Sugar refining clarification clean production process

A clean production and process technology, applied in food industry wastewater treatment, water/sludge/sewage treatment, filtration treatment, etc., can solve the problems of large one-time investment, high conversion of dry filter mud, high operation and maintenance costs, and achieve The effect of low light transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

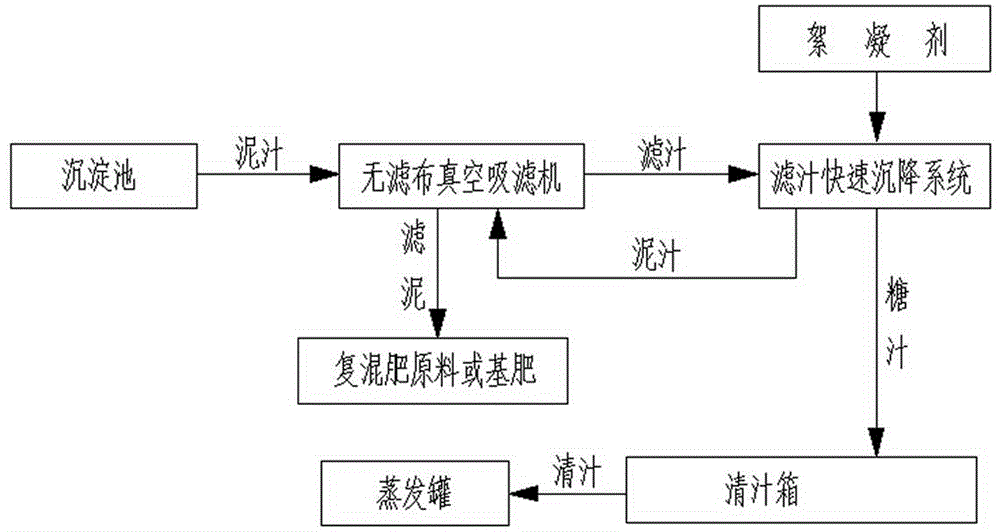

[0014] see figure 1 , a sugar clarification clean production process, its technological process is as follows:

[0015] First, the sedimentation tank sludge will enter the non-filter cloth vacuum suction filter for filtration and separation under the action of the non-filter cloth vacuum suction filter to obtain filtered juice and filter mud. The filter mud is used as raw material for compound fertilizer or directly supplied to Farmers make basal fertilizer, and the filtered juice enters the rapid sedimentation system of the filtered juice to further separate the solid and liquid under the action of the flocculant to obtain sugar juice and mud juice, and the obtained mud juice is returned to the non-filter cloth vacuum suction filter for re-filtering, while The obtained sugar juice is processed in the clear juice box, and the treated clear juice enters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com