A high-short-circuit-resistant, low-smoke, halogen-free home improvement wire and cable material and its preparation method

A technology for wire and cable materials and home decoration, applied in the field of wire and cable materials, can solve the problems of large investment, harsh operation protection, uneven cross-linking density, etc., and achieve the effect of high short-circuit resistance and improved mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

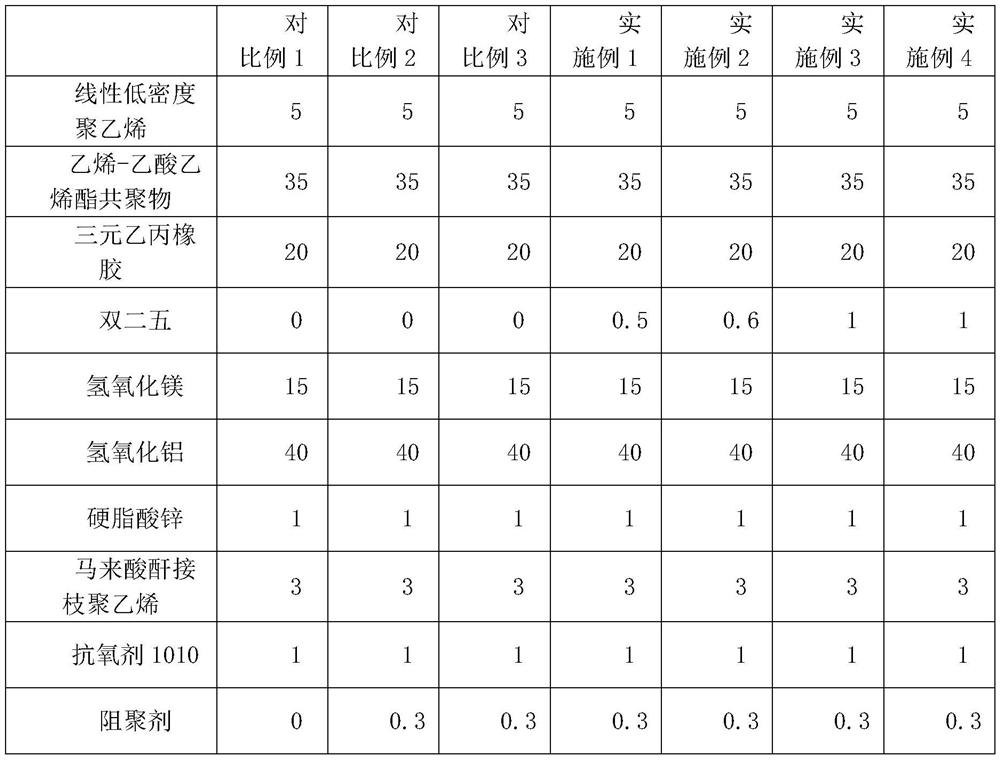

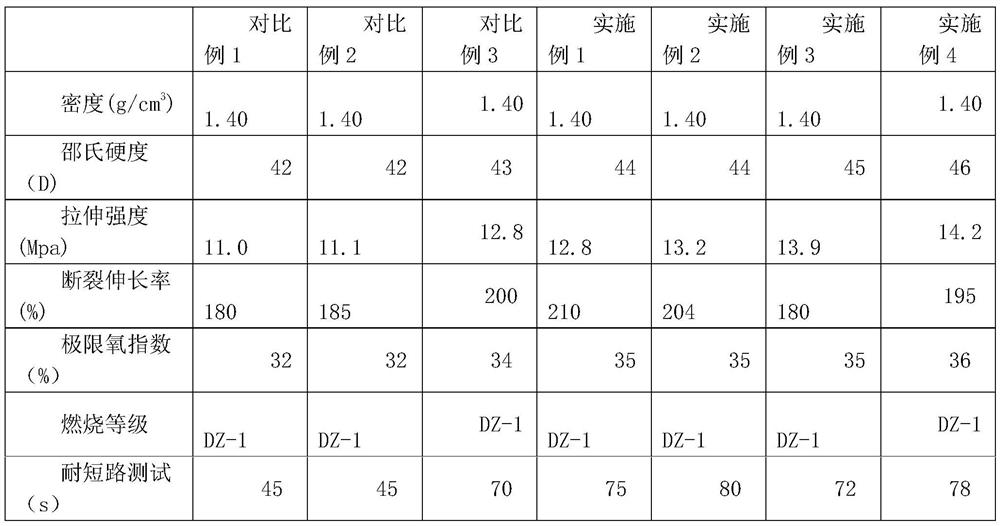

Embodiment 1

[0041] Mixing: Stir and mix the peroxide crosslinking agent, flame retardant, lubricant, compatibilizer, antioxidant, and polymerization inhibitor in a mixer. The mass components are as follows: 0.5 parts of peroxide crosslinking agent, flame retardant 55 parts of agent, 1 part of lubricant, 3 parts of compatibilizer, 1 part of antioxidant, 0.3 part of polymerization inhibitor.

[0042] Internal mixing: Mix the above mixed powder with 5 parts of linear low density polyethylene, 35 parts of ethylene-vinyl acetate copolymer, and 20 parts of EPDM rubber.

[0043] Dynamic vulcanization: Cable material is obtained by two-stage extrusion after banburying. The processing temperature of each section of single screw is: 90°C, 110°C, 125°C, 145°C, 150°C, and the temperature of each section of twin screw is: 150°C, 140°C , 130°C, 125°C, 115°C, 110°C, 100°C, the extrusion time is 1-2min.

[0044] The cable material is melted and extruded on the conductive wire core of the cable to form a...

Embodiment 2

[0047] Mixing: Stir and mix the peroxide crosslinking agent, flame retardant, lubricant, compatibilizer, antioxidant, and polymerization inhibitor in a mixer. The mass components are as follows: 0.6 parts of peroxide crosslinking agent, flame retardant 55 parts of agent, 1 part of lubricant, 3 parts of compatibilizer, 1 part of antioxidant, 0.3 part of polymerization inhibitor.

[0048] Internal mixing: Mix the above mixed powder with 5 parts of linear low density polyethylene, 35 parts of ethylene-vinyl acetate copolymer, and 20 parts of EPDM rubber.

[0049] Dynamic vulcanization: Cable material is obtained by two-stage extrusion after banburying. The processing temperature of each section of single screw is: 90°C, 110°C, 125°C, 145°C, 150°C, and the temperature of each section of twin screw is: 150°C, 140°C , 130°C, 125°C, 115°C, 110°C, 100°C, the extrusion time is 1-2min.

[0050] The cable material is melted and extruded on the conductive wire core of the cable to form a...

Embodiment 3

[0053] Mixing: Stir and mix the peroxide crosslinking agent, flame retardant, lubricant, compatibilizer, antioxidant, and polymerization inhibitor in a mixer. The mass components are as follows: 1 part of peroxide crosslinking agent, 1 part of flame retardant 55 parts of agent, 1 part of lubricant, 3 parts of compatibilizer, 1 part of antioxidant, 0.3 part of polymerization inhibitor.

[0054] Internal mixing: Mix the above mixed powder with 5 parts of linear low density polyethylene, 35 parts of ethylene-vinyl acetate copolymer, and 20 parts of EPDM rubber.

[0055] Dynamic vulcanization: Cable material is obtained by two-stage extrusion after banburying. The processing temperature of each section of single screw is: 90°C, 110°C, 125°C, 145°C, 150°C, and the temperature of each section of twin screw is: 150°C, 140°C , 130°C, 125°C, 115°C, 110°C, 100°C, the extrusion time is 1-2min.

[0056] The cable material is melted and extruded on the conductive wire core of the cable to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com