Quickly tensioned anti-crack assembled building by means of fastener

A fastener and anti-cracking technology, applied in construction and building construction, etc., can solve the problems of plate-to-plate cracking, poor assembly efficiency, lack of flexibility, etc., to improve functionality, maintain impact resistance and seismic performance , good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Most of the existing building structures are formed by fixed concrete pouring. The specific construction period is determined according to the actual building scale and technology, but the specific construction period is within the standard range. If you want to shorten the construction period and improve assembly efficiency, It is necessary to adjust its assembly and construction methods, and now the rapid construction of prefabricated structures is used to improve assembly efficiency and shorten the construction period.

[0072] However, in the past there were prefabricated parts, but the connection methods of prefabricated parts in the past still used conventional methods. The prefabricated parts were used as the most basic building base material, and the connection was also made by cement mortar and steel bars. The effect of shortening the working hours has not been achieved, and the structural strength of the prefabricated plate structure is low due to improper hand...

Embodiment 2

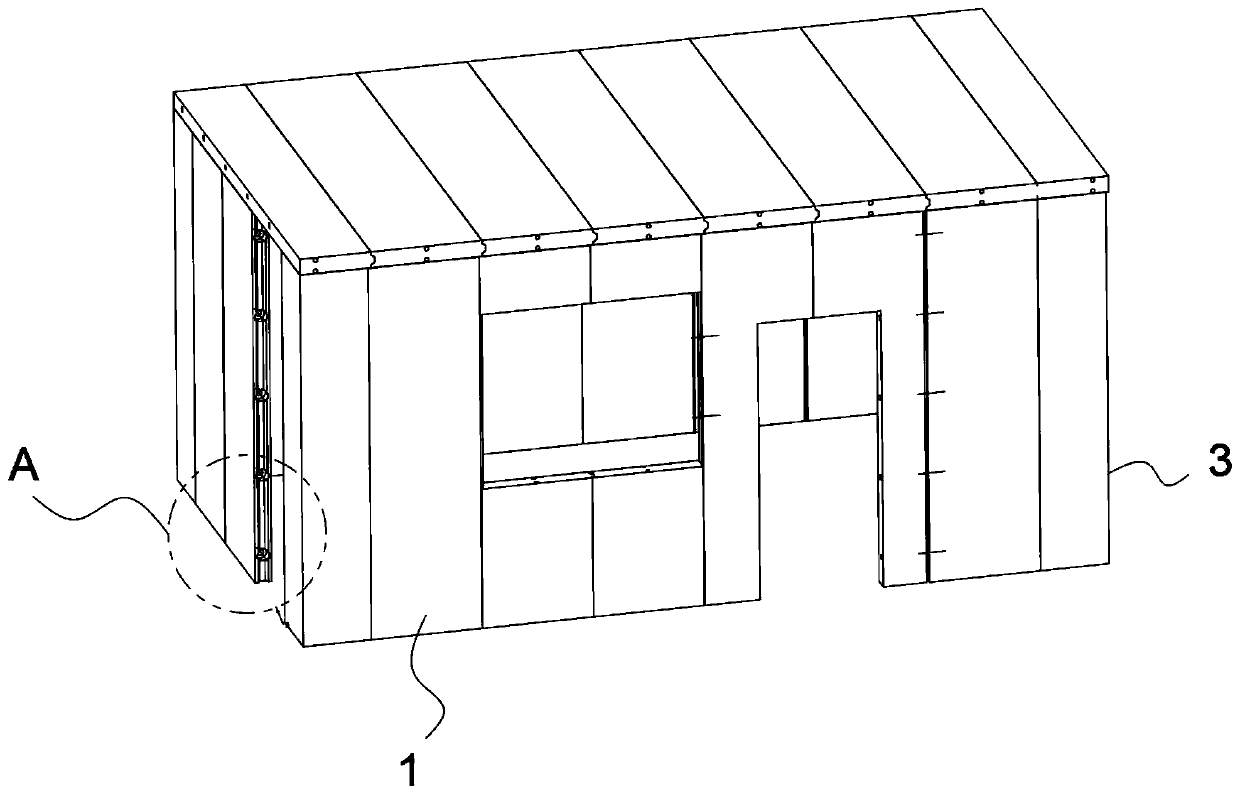

[0078] This embodiment discloses a crack-resistant prefabricated building that utilizes fasteners to quickly tighten, such as Figure 1-5 As shown, it includes a combined wall surface 1, a top plate 2 and a connecting plate 3. The combined wall surface 1 is connected to each other through the connecting plate 3 to form a ring-shaped structure set on the ground, and the roof plate 2 is set in a ring-shaped structure. The top opening of the building forms an independent space structure.

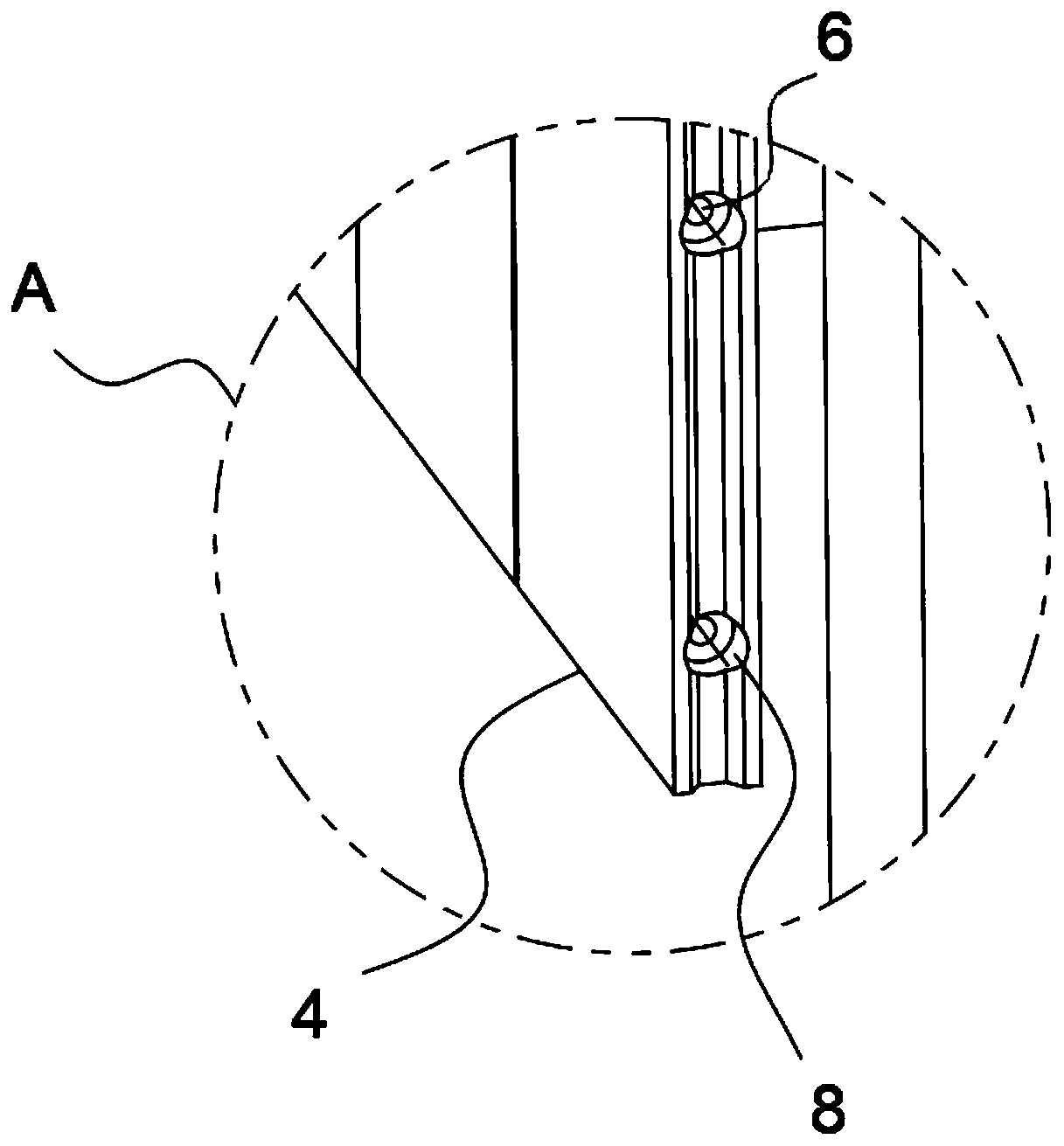

[0079] Wherein, the combined wall surface 1 and the top board 2 both include a plurality of base material plates 4 connected in parallel to each other, and the rod-shaped connectors passing through the entire base material plates 4 are passed between the base material plates 4, on the rod-shaped connectors Fasteners for fixing the base plate 4 are provided.

[0080] The base plate 4 is provided with a plurality of connection holes 6 along the arrangement direction of the base plate 4, and when...

Embodiment 3

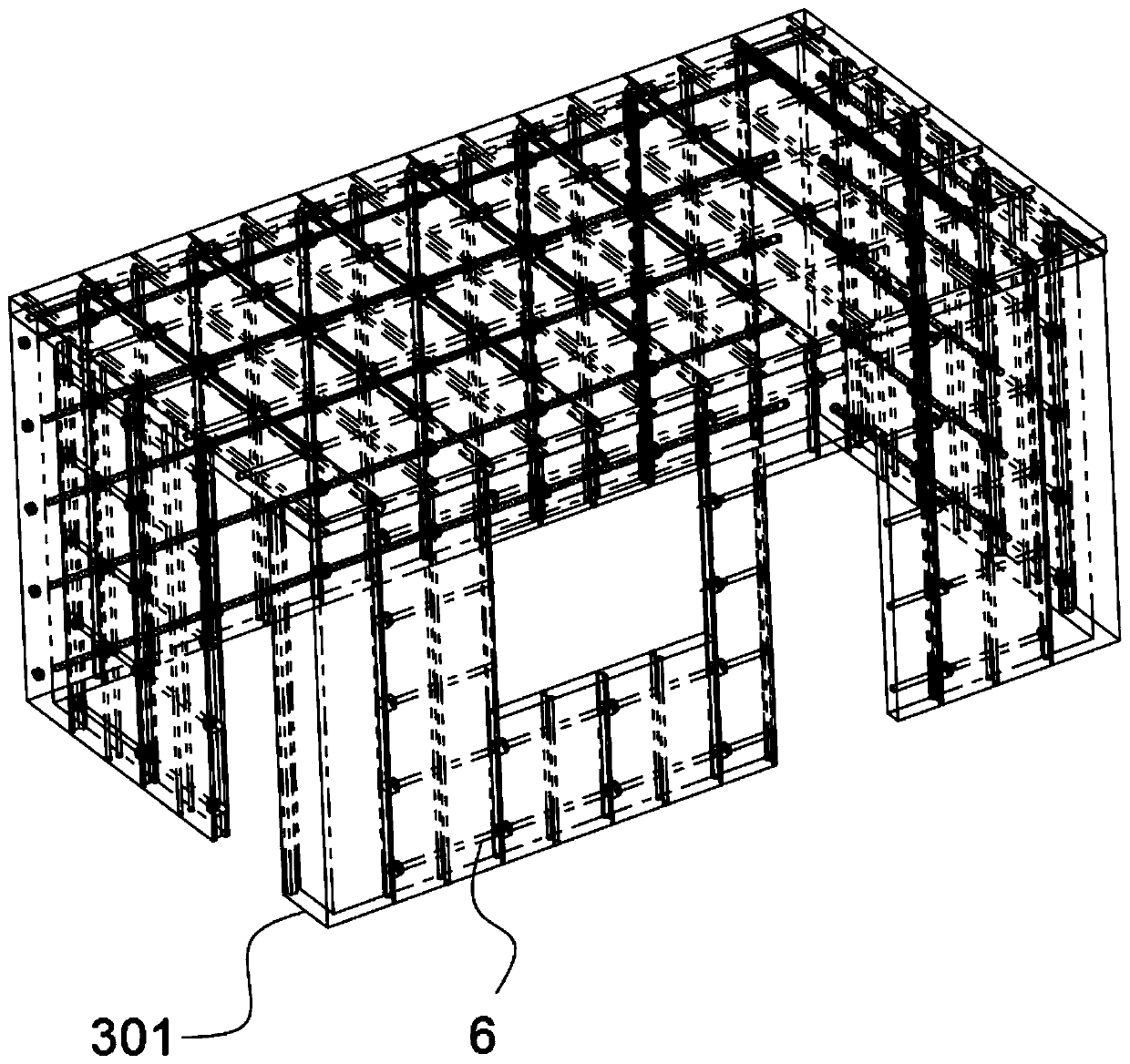

[0087] This embodiment discloses a crack-resistant prefabricated building that utilizes fasteners to quickly tighten, such as Figure 8-10 As shown, it includes a combined wall surface 1, a top plate 2 and a connecting plate 3. The combined wall surface 1 is connected to each other through the connecting plate 3 to form a ring-shaped structure set on the ground, and the roof plate 2 is set in a ring-shaped structure. The top opening of the building forms an independent space structure.

[0088] Wherein, the combined wall surface 1 and the top board 2 both include a plurality of base material plates 4 connected in parallel to each other, and the rod-shaped connectors passing through the entire base material plates 4 are passed between the base material plates 4, on the rod-shaped connectors Fasteners for fixing the base plate 4 are provided.

[0089] The base plate 4 is provided with a plurality of connection holes 6 along the arrangement direction of the base plate 4, and whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com