Self-floating low-flow-rate river power generation device capable of lifting along with water level

A power generation device, self-floating technology, applied in hydropower, reaction engines, floating buildings, etc., can solve the problems of large pollutant discharge, long cable deployment length, large vertical water level drop, etc., and achieve high power generation Efficiency, Ensuring Work Efficiency, Ensuring Sustainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

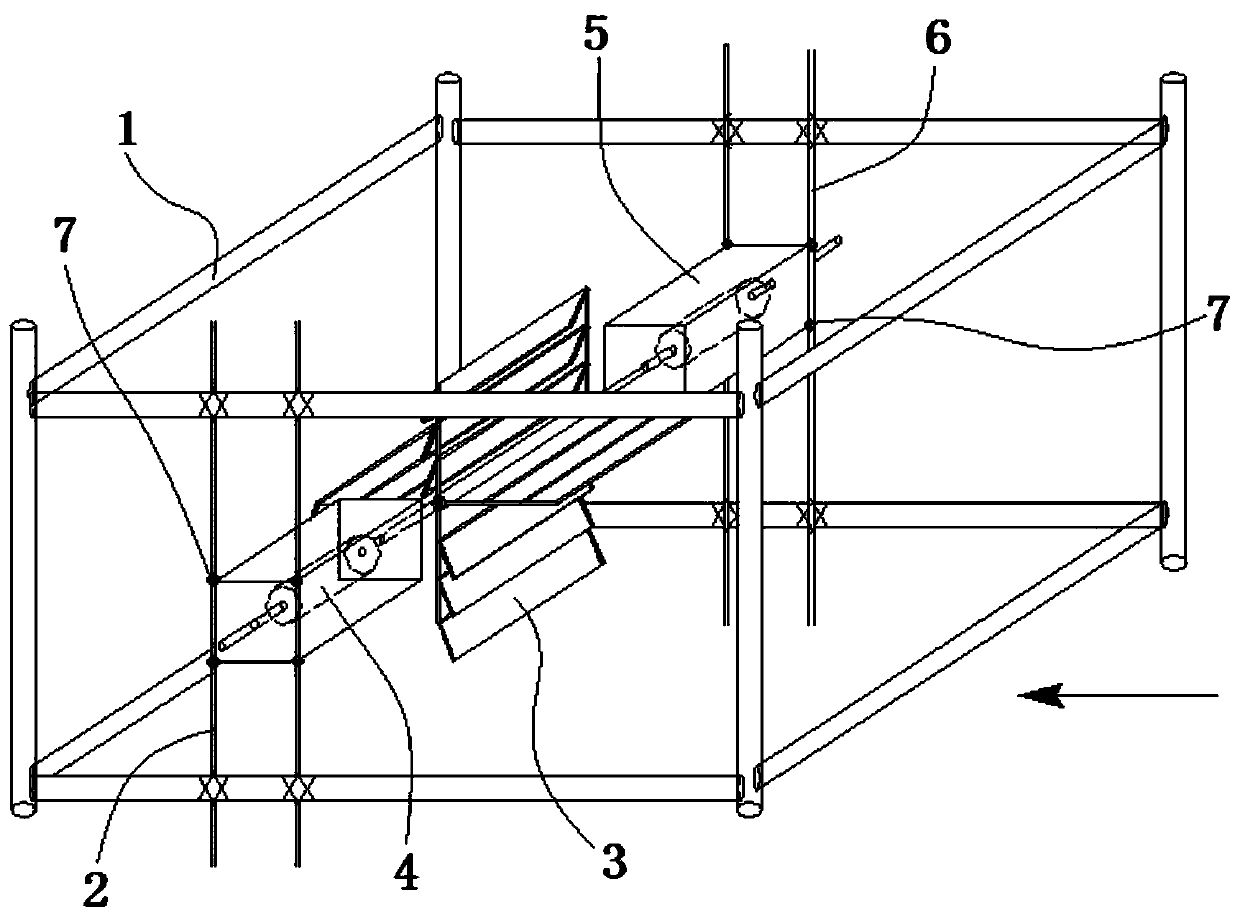

[0031] This embodiment discloses a self-floating low-velocity river power generation device that can rise and fall with the water level, including a rotating assembly 3, a power generation assembly 4, and a buoy 5 arranged under the overhead vertical wharf, and the materials used to make the rotating assembly 3 and the buoy 5 The density is less than that of water.

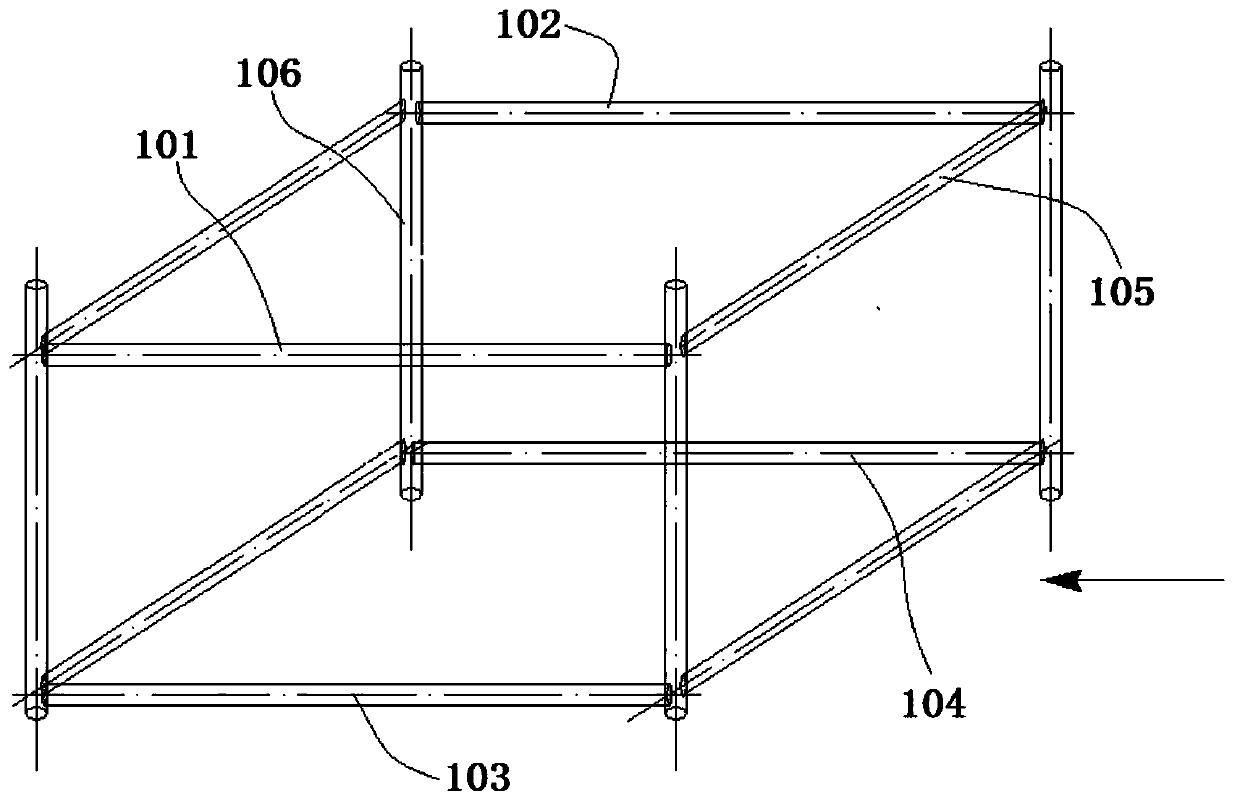

[0032] Several square support frames 1 are connected to the lower end of the overhead vertical wharf. see figure 2 , the square supporting frame 1 includes beam I101, beam II102, beam III103, beam IV104, four longitudinal beams 105 and four columns 106, beam I101, beam II102 and two longitudinal beams 105 spliced into an upper rectangular frame, beam III103 , beam IV 104 and two longitudinal beams 105 are spliced into a lower rectangular frame, and four columns 106 connect the upper rectangular frame and the lower rectangular frame as a whole.

[0033] The beam I 101 , beam II 102 , beam III 103 and beam IV...

Embodiment 2

[0047] This embodiment discloses a self-floating low-velocity river power generation device that can rise and fall with the water level, including a rotating assembly 3, a power generation assembly 4, and a buoy 5 arranged under the overhead vertical wharf, and the materials used to make the rotating assembly 3 and the buoy 5 The density is less than that of water.

[0048] Several square support frames 1 are connected to the lower end of the overhead vertical wharf. see figure 2 , the square supporting frame 1 includes beam I101, beam II102, beam III103, beam IV104, four longitudinal beams 105 and four columns 106, beam I101, beam II102 and two longitudinal beams 105 spliced into an upper rectangular frame, beam III103 , beam IV 104 and two longitudinal beams 105 are spliced into a lower rectangular frame, and four columns 106 connect the upper rectangular frame and the lower rectangular frame as a whole.

[0049] The beam I 101 , beam II 102 , beam III 103 and beam IV...

Embodiment 3

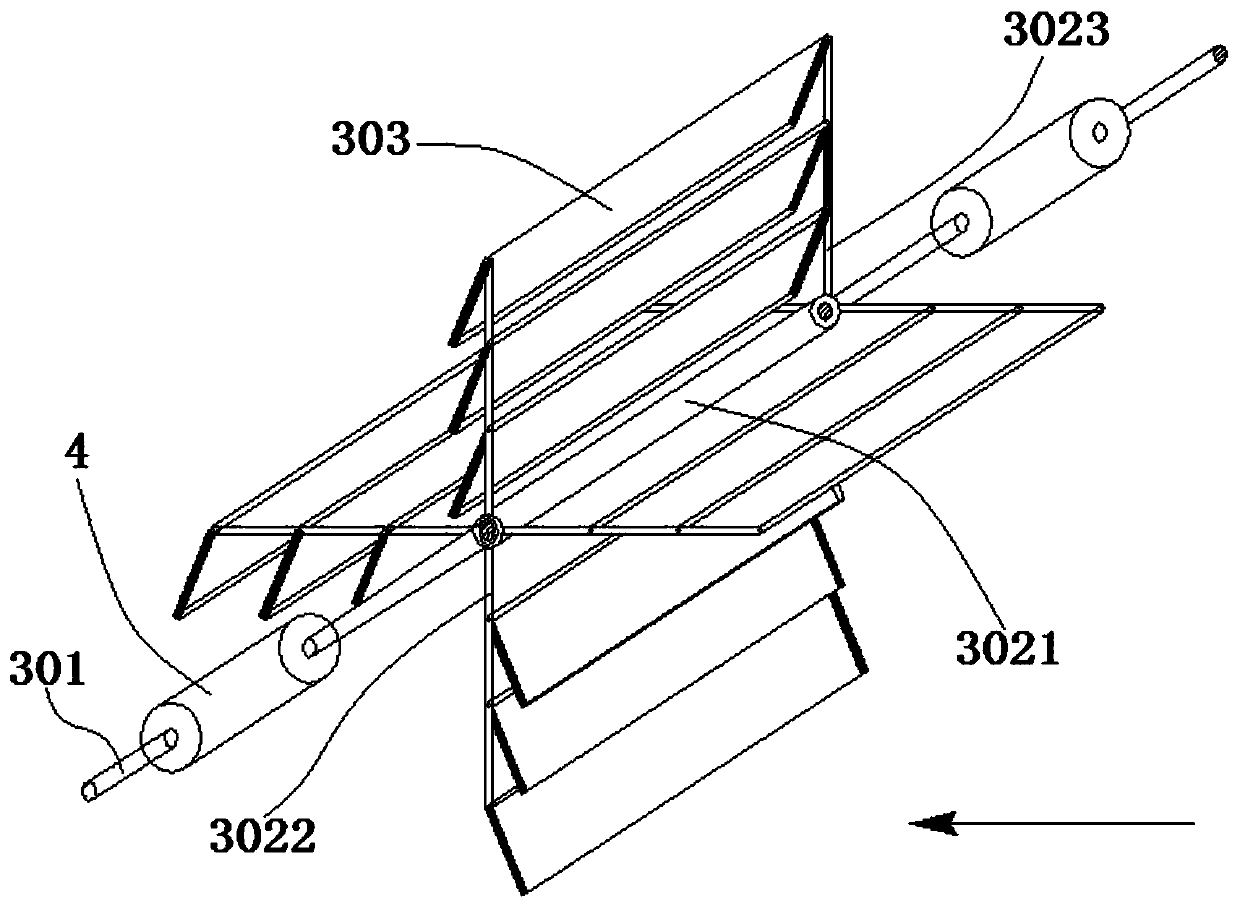

[0060] The main structure of this embodiment is the same as that of Embodiment 3, further, see Figure 5 In Figure (2), when the steel pipe I, steel pipe II, steel pipe III, steel pipe IV, steel pipe V, steel pipe VI, steel pipe VII and steel pipe VIII are all curved steel pipes, the plate surface of the blade 303 is a curved surface. When working, the concave side of steel pipe I, steel pipe II, steel pipe III, steel pipe IV, steel pipe V, steel pipe VI, steel pipe VII and steel pipe VIII is the side facing the water, and when several blades 303 are closed, the curved steel pipe The curved surface is marked as curved surface L1, and several blades 303 hinged on the arc-shaped steel pipe are all on the curved surface L1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com