Fluid conveying device

A technology for fluid transportation and installation, which is applied in the direction of pump devices, noise reduction devices, exhaust devices, etc. It can solve the problems of reducing the working efficiency of urea solution and measuring accuracy, and achieve the goal of eliminating air bubbles, ensuring working efficiency and improving the waterproof level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

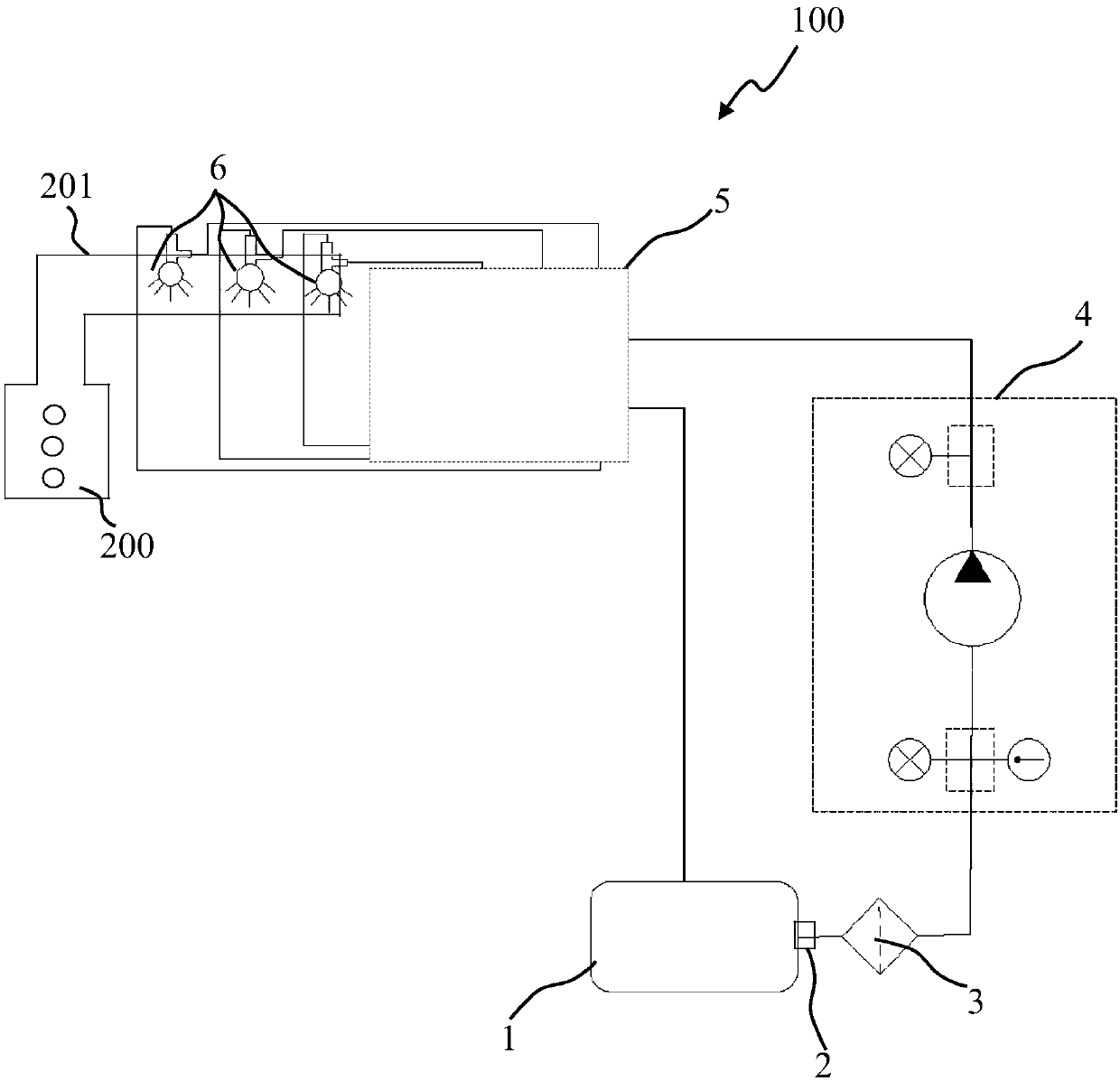

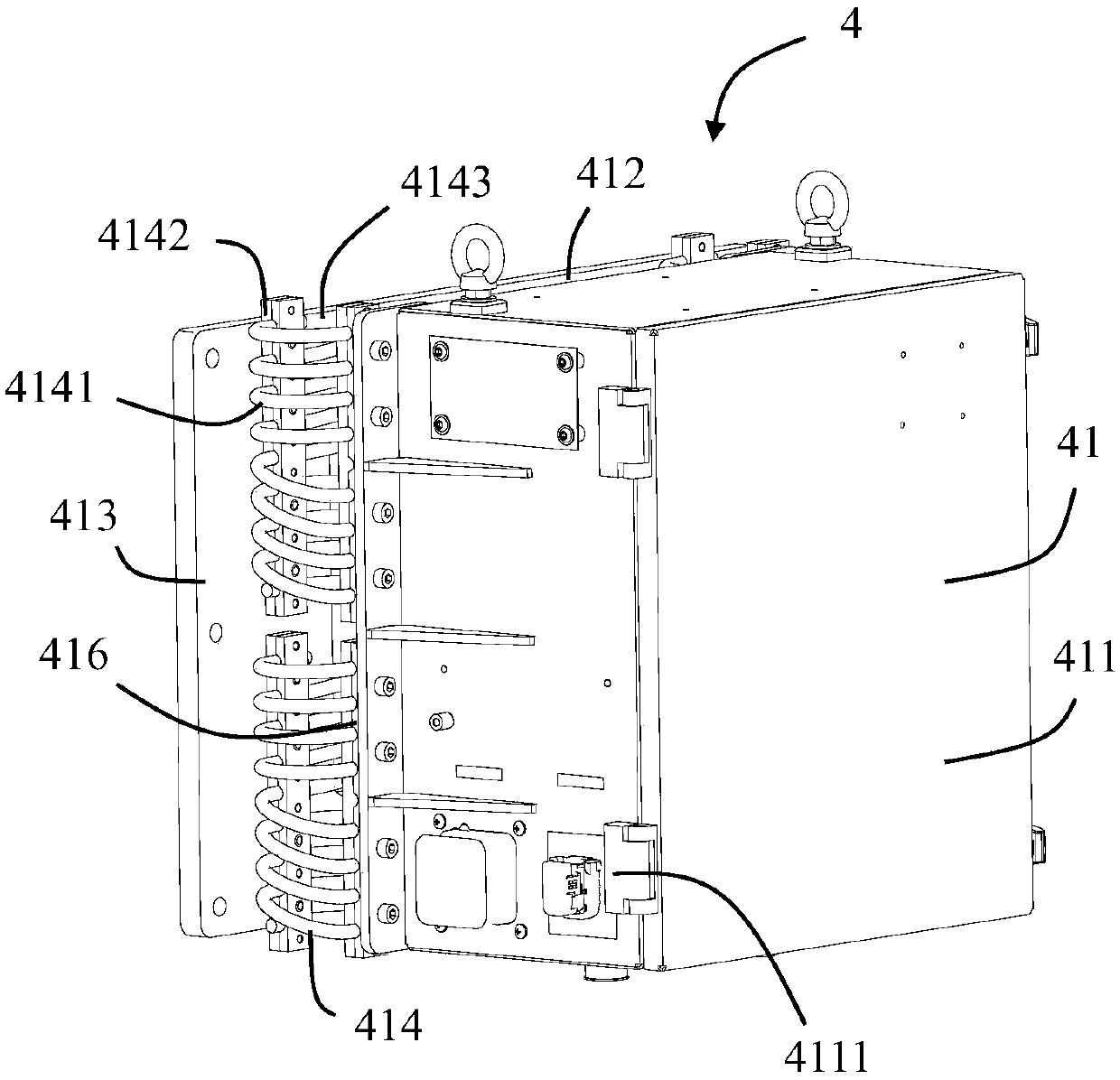

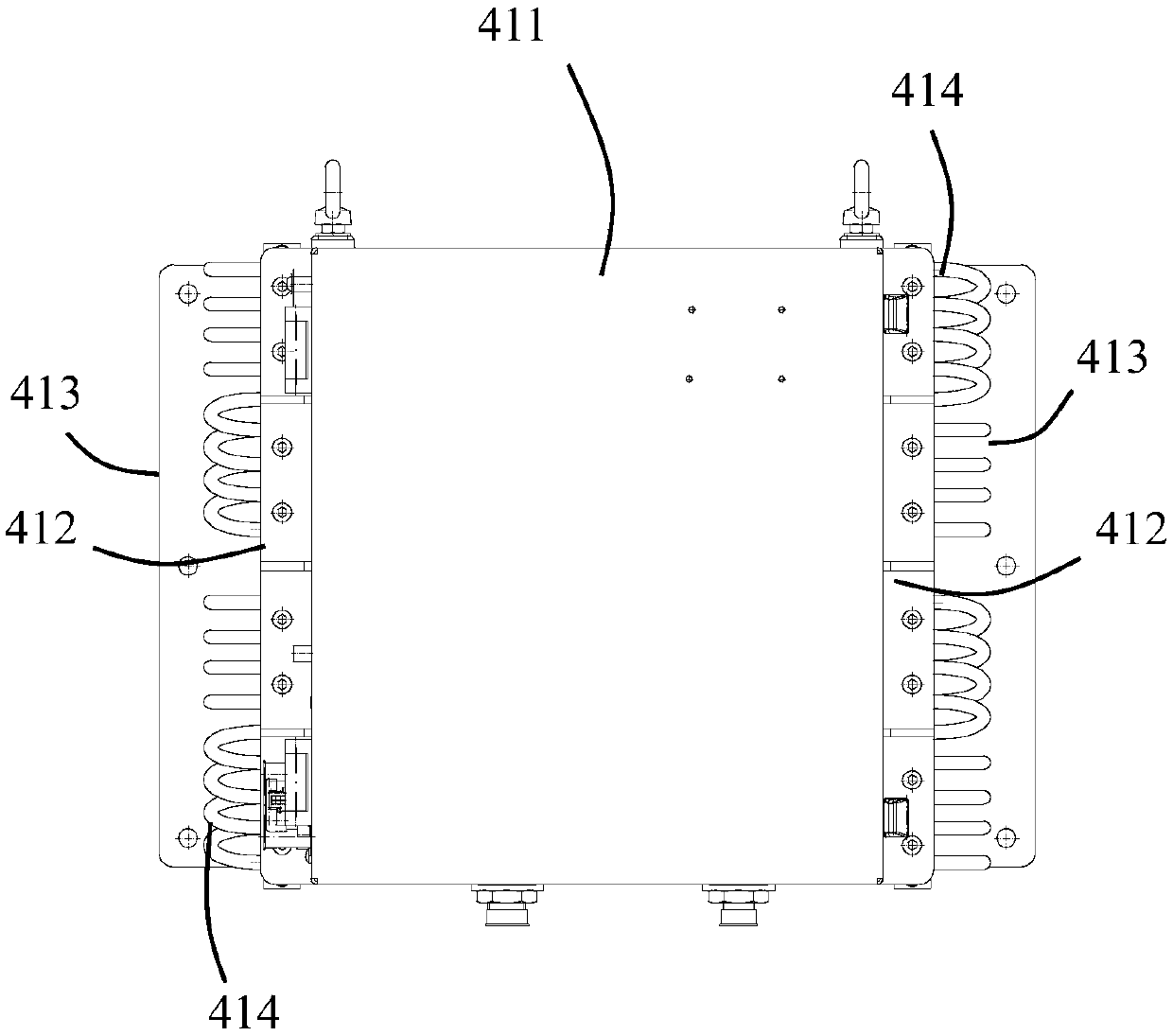

[0022] Please refer to figure 1 As shown, the present invention discloses an engine exhaust gas treatment system 100 , which is applied to the exhaust gas treatment of an engine 200 . The engine exhaust treatment system 100 includes a urea tank 1, a sensor integration device 2 connected to the urea tank 1, a filter 3 connected downstream of the sensor integration device 2, and a fluid delivery device for delivering the urea solution 4. A common rail 5 connected to the fluid delivery device 4 and a nozzle 6 connected to the common rail 5 . In the illustrated embodiment of the present invention, the engine 200 is a high-power engine whose power generally exceeds 500 kilowatts. Correspondingly, the nozzle 6 usually has a plurality. The nozzle 6 is used for spraying urea solution into the engine exhaust pipe 201 . The atomized urea solution is decomposed into ammonia gas in the engine exhaust pipe 201 , and the ammonia gas can react with nitrogen oxides in the exhaust gas, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com