A bionic strain sensor with omnidirectional perception and its preparation method

A strain sensor and bionic technology, applied in the field of strain sensors, can solve the problems of poor accuracy, sensitivity and reproducibility of strain measurement components, and achieve the effect of simple structure, high sensitivity and enhanced reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] (1) Preparation of bionic strain sensor with omnidirectional perception

[0069] (1.1) Provide a polydimethylsiloxane (PDMS) substrate;

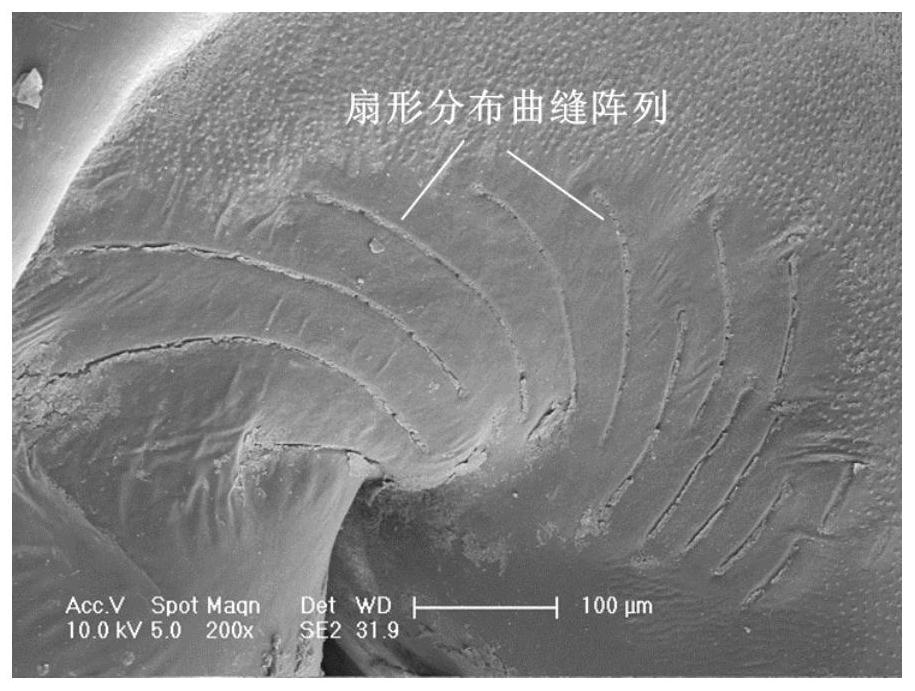

[0070] (1.2) Then the micro-nano groove array is prepared on the polydimethylsiloxane substrate by mechanical cutting, and the micro-nano groove array is recessed on the polydimethylsiloxane substrate; the micro-nano groove The groove array includes 24 identical micro-nano grooves, and the micro-nano grooves are evenly distributed around the circumference of the virtual central circle to form a circular array;

[0071] (1.3) Then cover the PDMS substrate and the micro-nano groove array by sputtering and plate a silver nanoparticle layer;

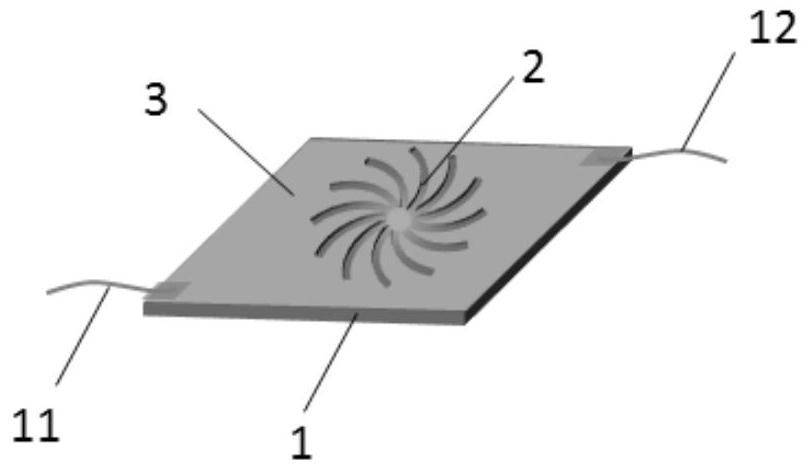

[0072](1.4) Finally, the first electrode and the second electrode are prepared on the silver nanoparticle layer. The first electrode is a copper sheet, and the second electrode is a conductive silver glue, that is, an omnidirectional sensing bionic strain sensor is obtained. Its three-dimensional s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com