Solid medium heat conduction performance measuring device

A technology of measuring device and solid medium, which is applied in the field of characterization devices of thermal conductivity of materials, can solve the problems of high cost, complicated structure of testing device, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

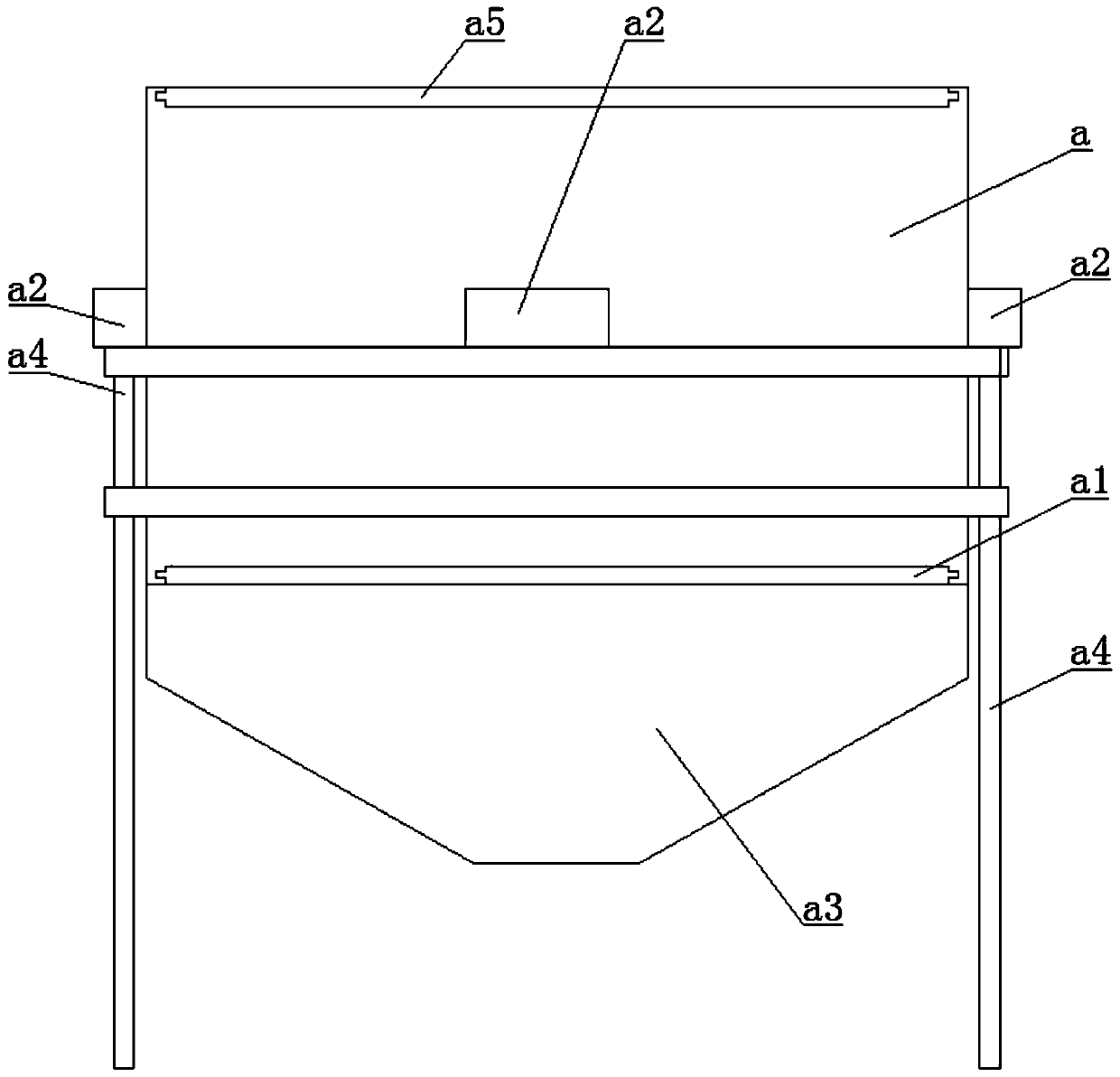

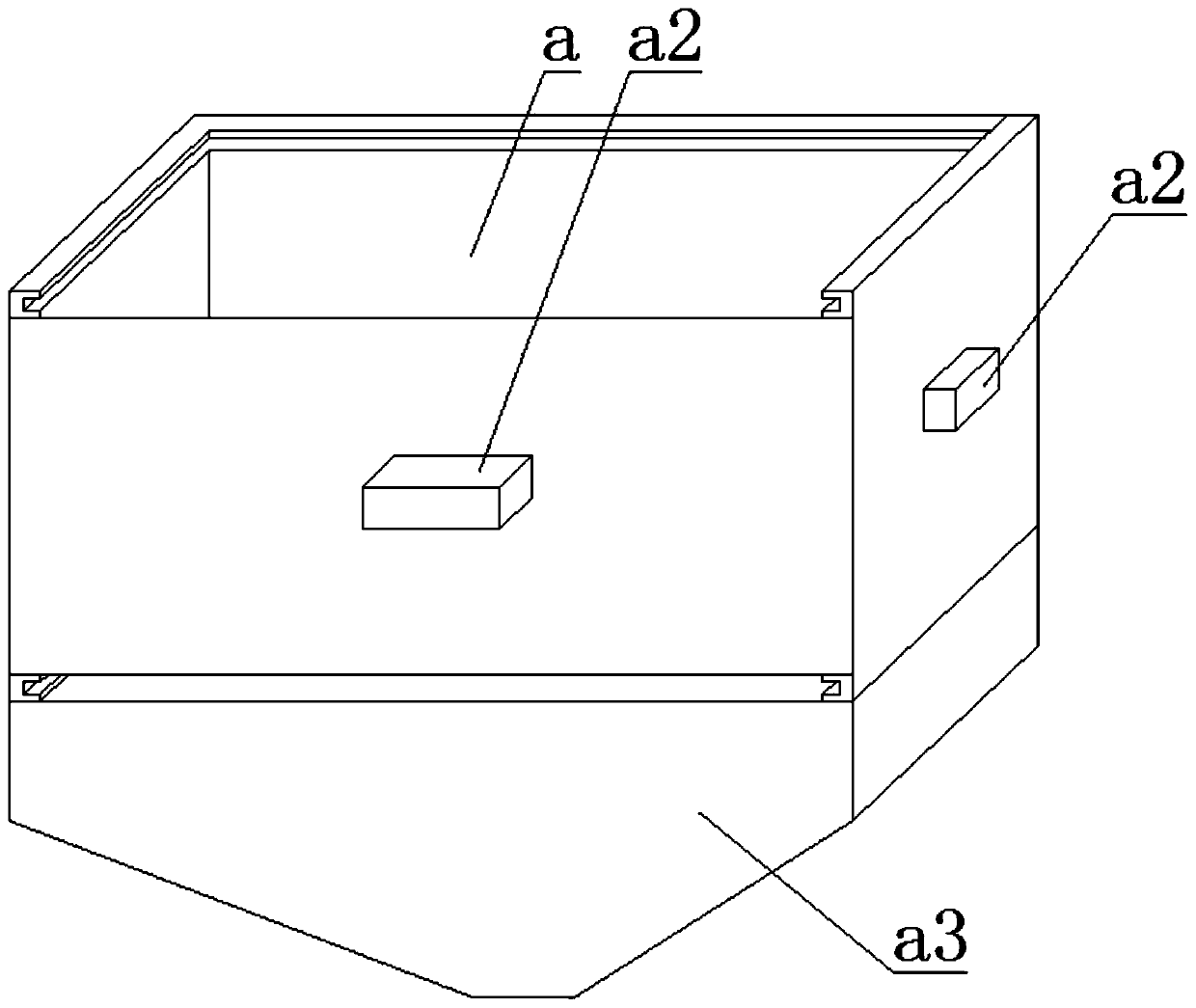

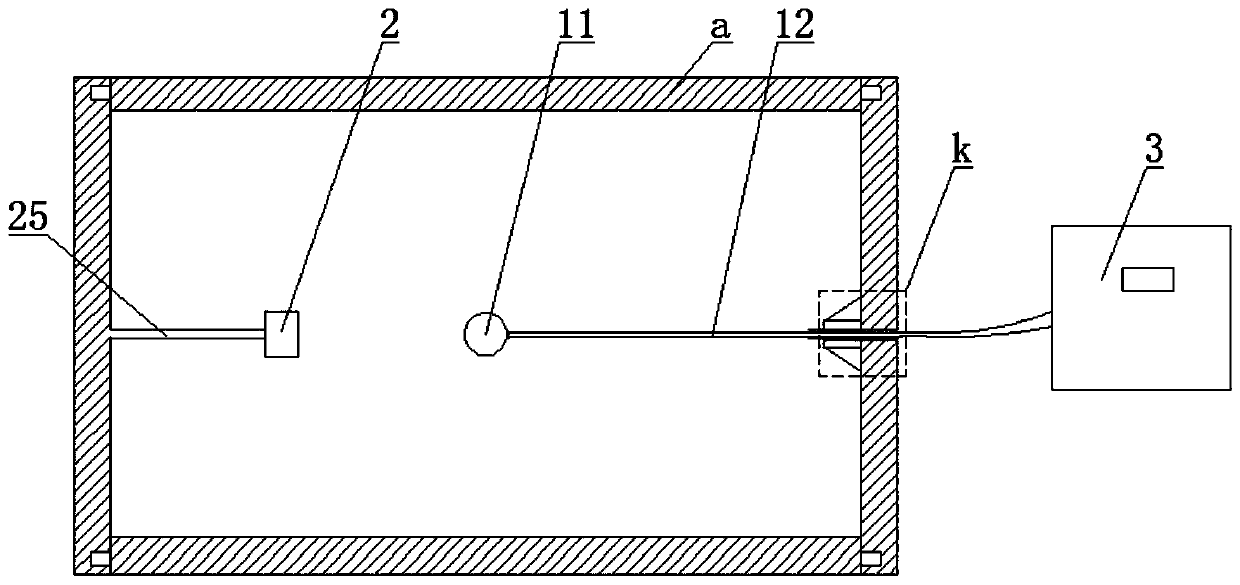

[0054] Such as figure 1 , 2 , 3, a solid medium thermal conductivity measurement device, including a box a and a control display module 3, the box a is provided with a heat source 1 and a first temperature sensing module 2, the heat source 1 and the first temperature sensing module The modules 2 are arranged at intervals, and the heat source 1 and the first temperature sensing module 2 are connected to the control display module 3;

[0055] The top of the box body a is provided with a feed opening, the bottom of the box body a is provided with a discharge opening, the discharge opening is covered with a baffle plate a1, and the feed opening is covered with a shielding plate a5, so A return hopper a3 is provided below the box body a.

[0056] The side wall of the box body a is provided with a material baffle socket corresponding to the material baffle a1, and the inner wall of the box a is provided with a material baffle slot corresponding to the material baffle a1. The mate...

Embodiment 2

[0089] Use the above device to carry out constant temperature heating, and use the specific steps of method ① as follows:

[0090] Step 1, placing the material to be tested and the box a at room temperature (25°C) for at least 24 hours, so that the temperature of the material to be tested and the box a is consistent with room temperature;

[0091] Step 2. At room temperature, heat the heat source 1 to the target temperature and maintain it, and put the material to be tested into the box a from the feeding port within a predetermined time, so that the box a is filled with the material to be tested ;

[0092] Step 3, taking the time when the material to be tested is started to be added as the initial moment, continuously acquire and record the temperature data measured by the first temperature sensing module 2 until the temperature measured by the first temperature sensing module 2 is stable, and plot the temperature - time curve; due to the constant temperature heating, the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com