Deslagging scraper device for oven return roller

A technology of scraper device and return roller, which is applied in the field of papermaking equipment, can solve the problems of potential safety hazards, tearing, paper wrapping and difficult cleaning, etc., and achieve the effect of improving equipment automation, reducing potential safety hazards, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

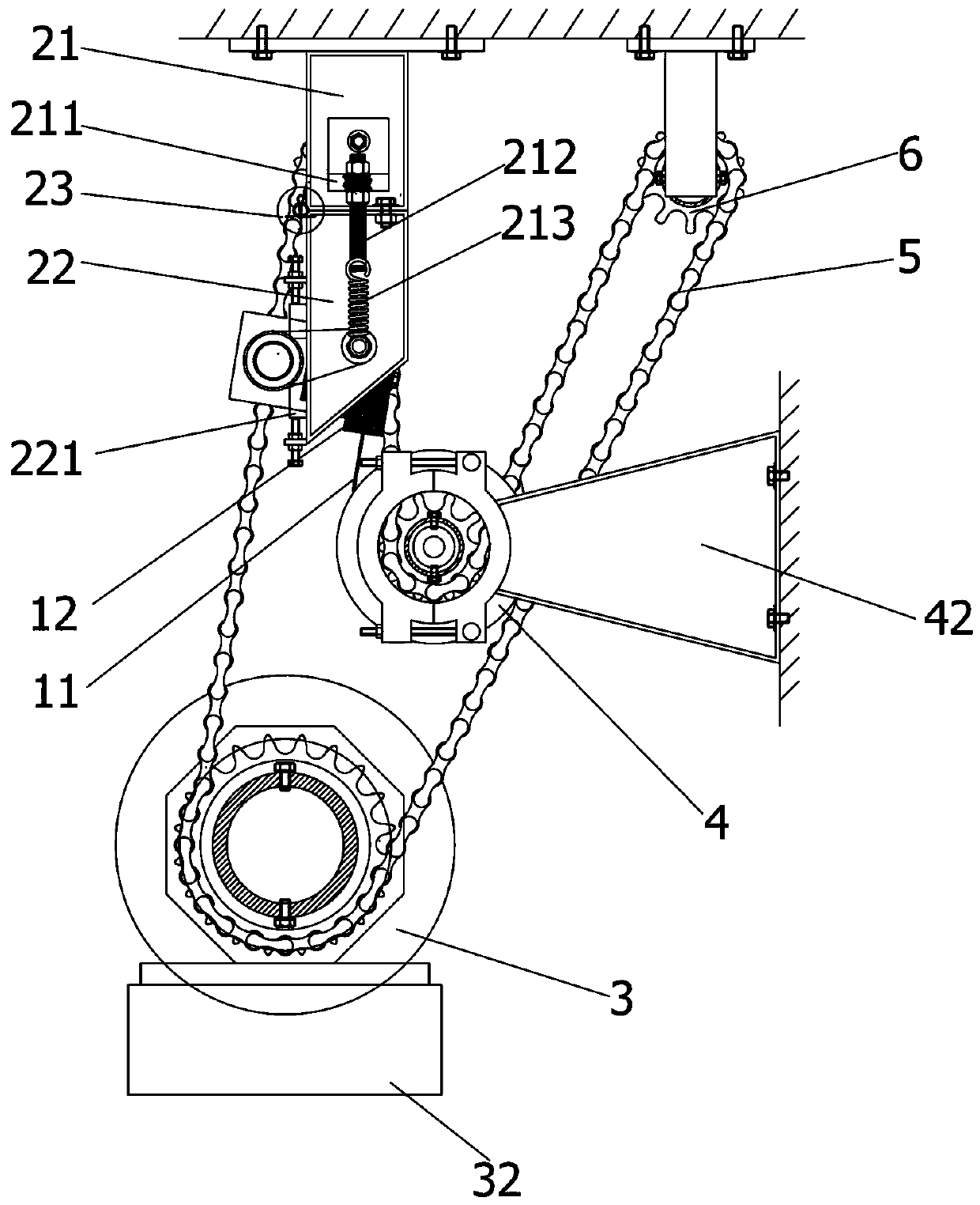

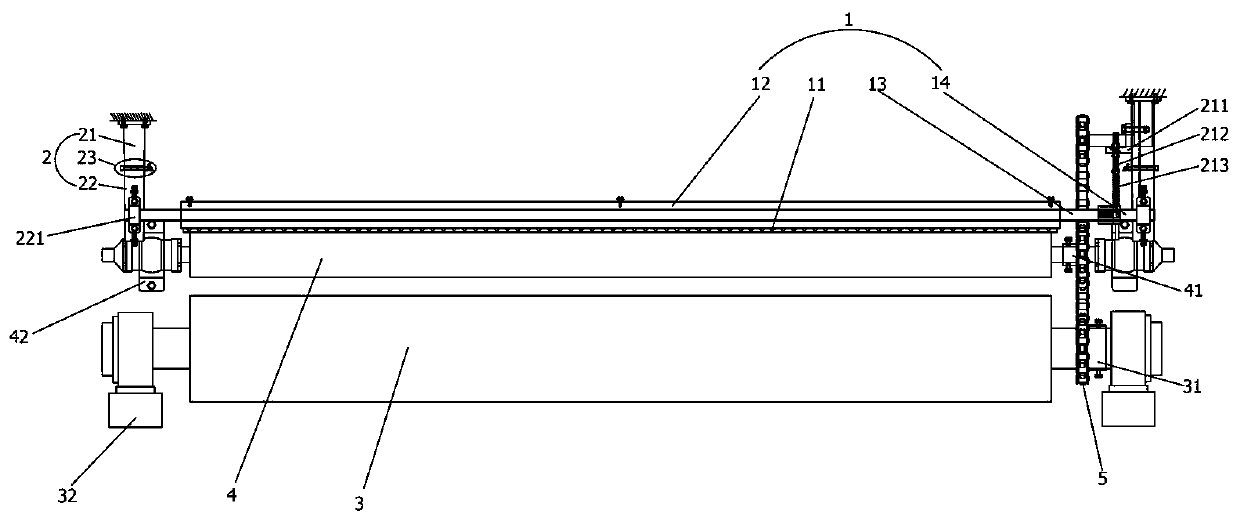

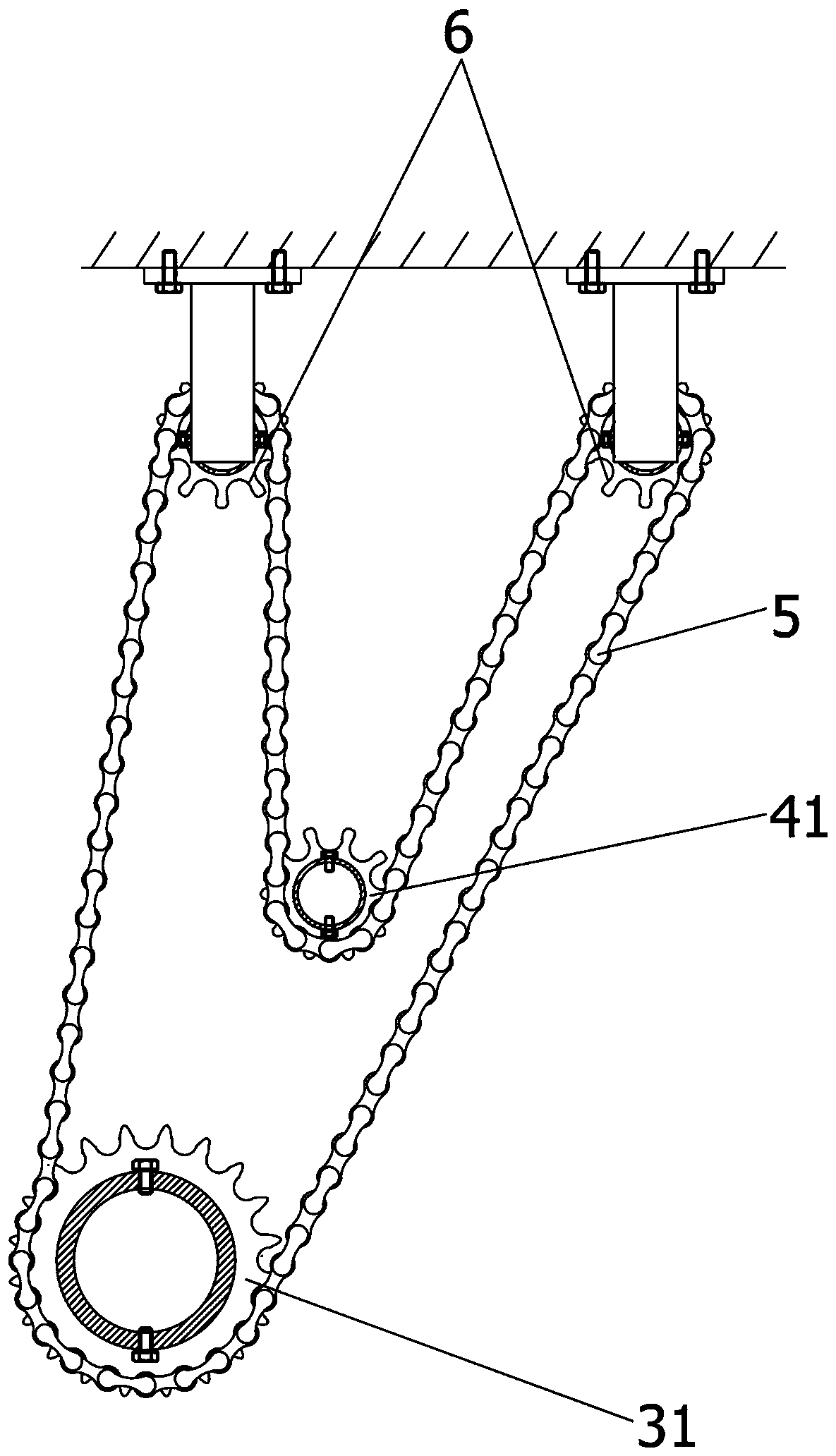

[0031] Example one: such as Figures 1 to 7 As shown, it is only one of the embodiments of the present invention. A scum scraper device for an oven returning roller includes a driving roller 3, a returning roller 4, and a transmission chain 5 for connecting the driving roller 3 and the returning roller 4 And an adjusting sprocket 6 for adjusting the transmission chain 5, further comprising a scraper portion 1 arranged above the turning roller 3 and an adjusting portion 2 for adjusting the position of the scraper portion 1, the scraper portion 1 includes The scraper 11, the scraper holder 12 for clamping the scraper 11, the scraper shaft 13 connected with the scraper holder 12, and the adjusting member 14 for connecting the scraper shaft 13 and the adjusting part 2, the adjustment The part 2 includes an upper fixing frame 21 connected with the oven wall, a lower fixing frame 22 connected with the adjusting member 14, and a connecting frame 23 for connecting the upper fixing fram...

Embodiment 2

[0040] Example two, still as Figures 1 to 7 Shown is only one of the embodiments of the present invention. In order to make the cleaning effect and stability of the slag removing scraper device of an oven turning back roller of the present invention better, the present invention also has the following design:

[0041] First, the number of the seated bearing 221 is at least one. The scraper shaft 13 needs to be rotated to adjust the angle between the scraper 11 and the return roller 4, so fixed belt bearings 221 are installed at both ends of the scraper shaft 13 to make the scraper shaft 13 meet the rotation requirements.

[0042] Moreover, the extending direction of the sliding groove 222 is the same as the extending direction of the adjusting screw 212 and the tension spring 213, which ensures that the seated bearing 221 slides to drive the position of the adjusting screw 212 to change.

[0043] Then, a fixed welding block 121 is provided at the connection between the scraper base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com