Grinding fixture and straight pipe inner wall arc grinder

A technology for grinding jigs and clamping bodies, which is applied in the direction of grinding racks, grinding machine parts, and machine tools designed for grinding the rotating surface of workpieces, etc., which can solve the problems of low efficiency and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

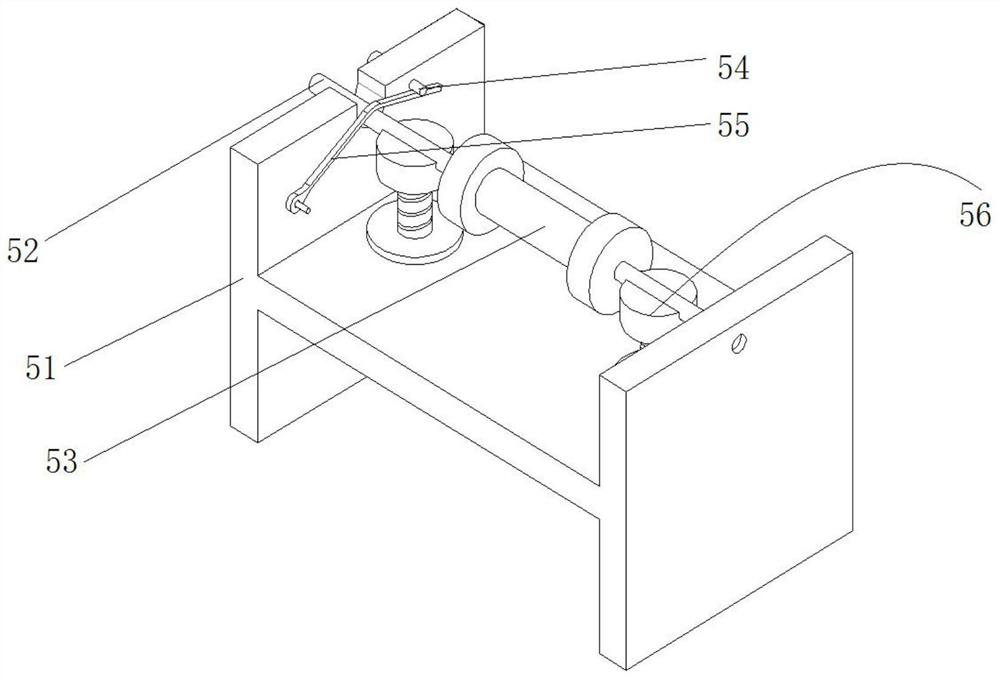

[0034] like Figure 1-4 As shown in , according to an embodiment of the present invention, a grinding fixture is provided, including a fixture body 51 , a grinding roller shaft 52 , a grinding roller 53 , a pin 54 , a pressing rod 55 and a supporting mechanism 56 . The jig body 51 is used as the basic part of the whole grinding jig, and all elements and mechanisms of the grinding jig are installed on it to make it a whole. Rigid materials such as cast iron or marble are preferred in the material selection of the clamp body 51 to avoid deformation of the clamp body 51 , resulting in processing errors of the glass tube. The support mechanism 56 is arranged on the top of the chuck body 51, and the top of the support mechanism 56 is provided with a placement groove, and the grinding roller shaft 52 is embedded in the groove, so as to position and support the grinding roller shaft 52. The first end of the grinding roller shaft 52 is installed in the socket at one end of the chuck ...

Embodiment 2

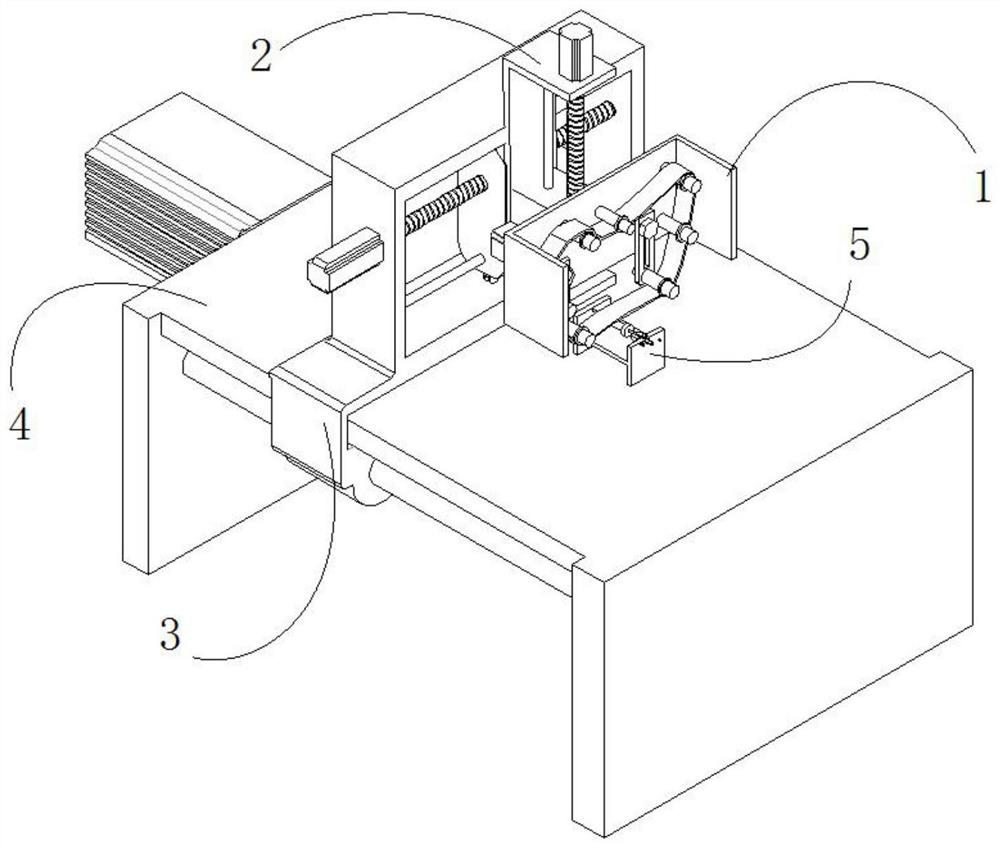

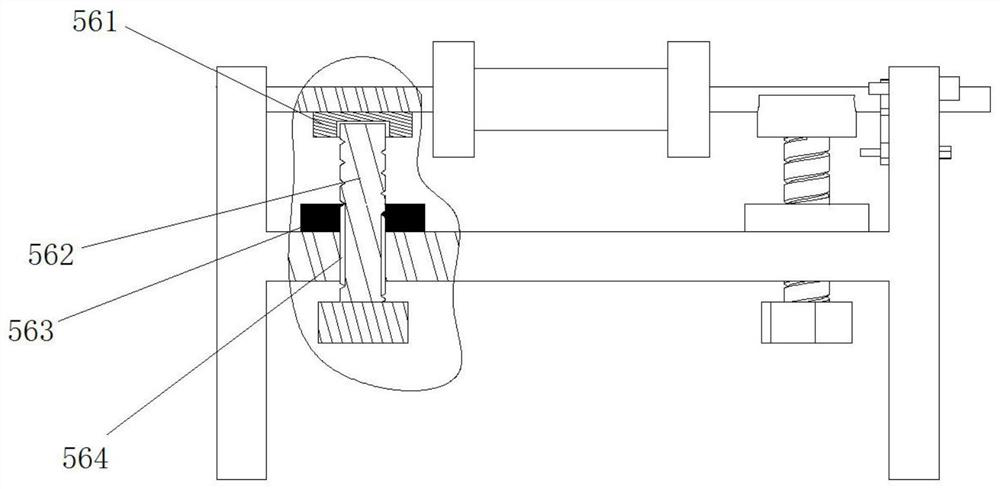

[0039] like Figure 5-9 As shown in , according to Embodiment 2 of the present invention, a straight pipe inner wall arc grinding machine is provided, including a grinding fixture, an actuator 1 and a frame, the grinding fixture is fixed on the top of the frame, and the actuator 1 is located above the grinding jig. Further speaking, the grinding jig and the top of the frame can be fixed by screw connection, and at the same time can also be fixed by insertion. The specific selection can be determined according to the processing accuracy of the glass tube. When the processing accuracy is less than 4 microns, the grinding jig uses a screw top. Fixed, when the machining accuracy is greater than 4 microns, the grinding fixture is fixed by plugging.

[0040] In a specific embodiment 2 of the present invention, the actuator 1 includes an actuator 11, an output roller 12, an adjustment roller 13, a protective cover 15, a transmission roller 16, a transmission belt 17, and the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com