Space on-orbit refueling self-locking type butt-joint interface device

A technology of docking interface and filling interface, which is applied in the field of docking interface devices, can solve the problems of cumbersome mechanism, liquid splash leakage in the pipeline, jamming, etc., and achieve the effects of avoiding stress concentration, reducing the risk of fracture, and reliable connection and locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] For ease of description, the locking spheres are all referred to as "steel balls" in this manual, but the material of the spheres is not necessarily made of steel. The specific selection of materials should be based on actual engineering needs, considering the various properties of the material. In the case, confirm it.

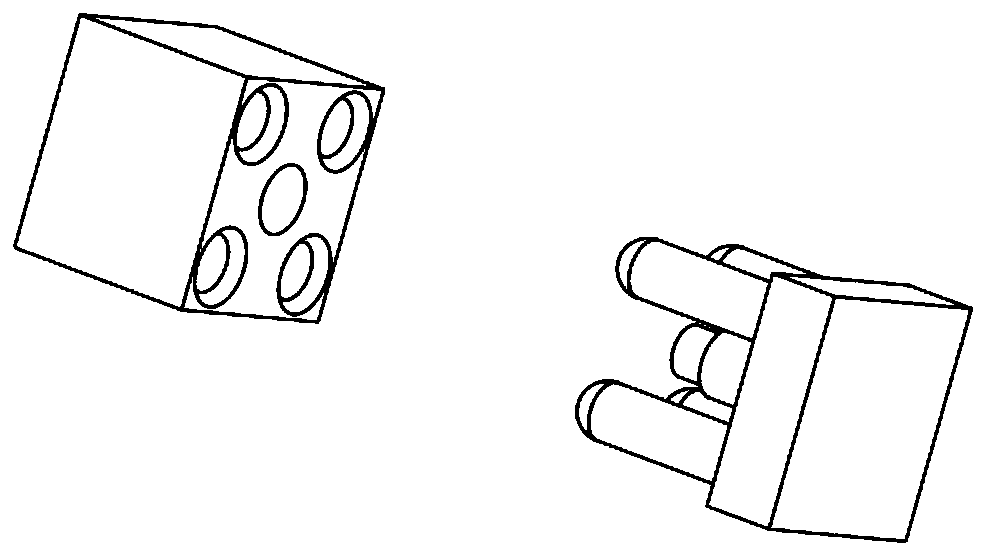

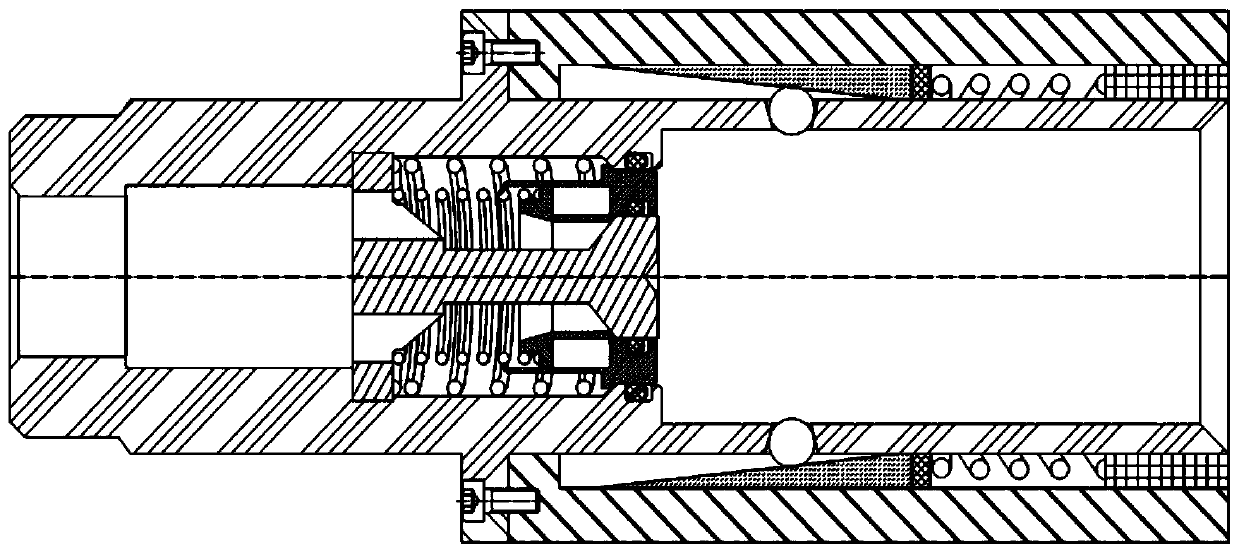

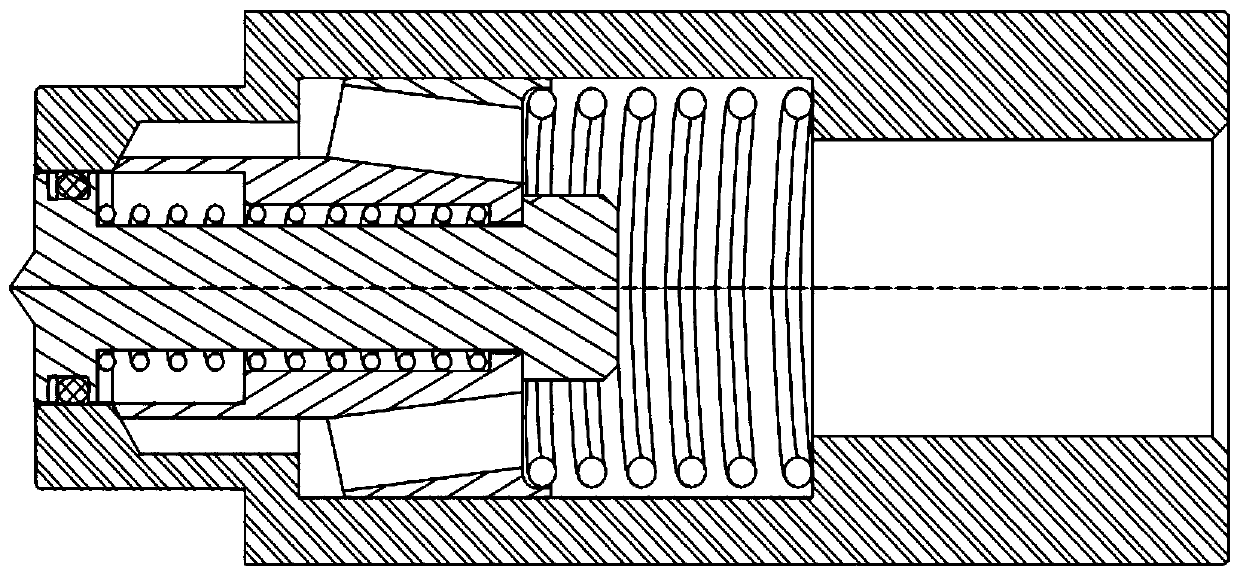

[0047] The present invention includes two parts, the injection interface and the filling interface, specifically including the injection interface fixed valve core 1, the injection interface internal outer spring 2, the injection interface internal spring 3, the first floating body 4, the second floating body 5, and the injection spring shell Body 6, Steel Ball 7, Locking Part Housing 8, Inner Taper Sleeve 9, Permanent Magnet 10, Locking Spring 11, Electromagnetic Coil Part 12, Filling Interface Outer Shell 13, Filling Joint Internal Outer Spring 14, Filling Joint The floating spool 15, the internal spring 16 of the filling joint, the No. 3 floating bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com