Fast packaging and pouring device for concrete pipelines and construction method of fast packaging and pouring device for concrete pipelines

A technology of concrete and rapid packaging, which is applied in the direction of construction and infrastructure engineering, etc. It can solve the problems of accelerating the ground subsidence of the lower end of the concrete pipe, the narrow operation space of the sealing width, and the interruption of urban water supply and drainage, etc., and achieves good quality and use effect. The structure and method are simple and practical, and the effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

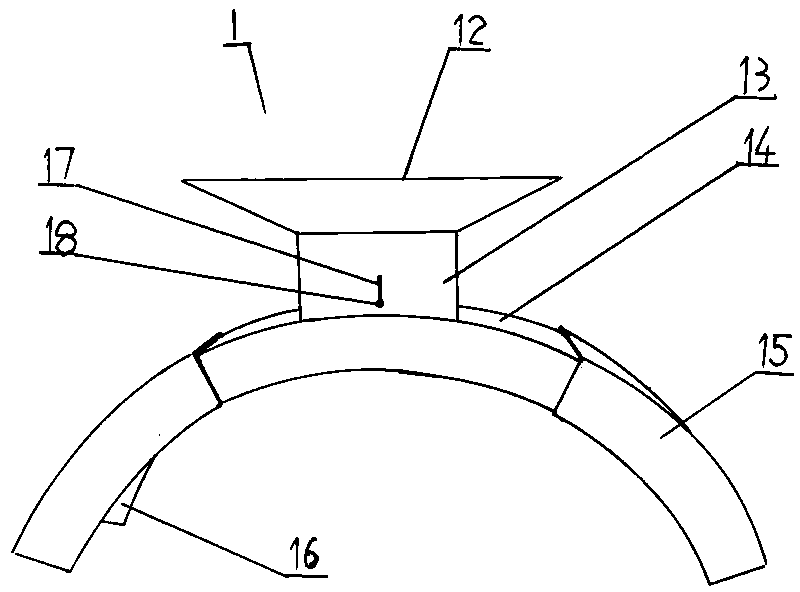

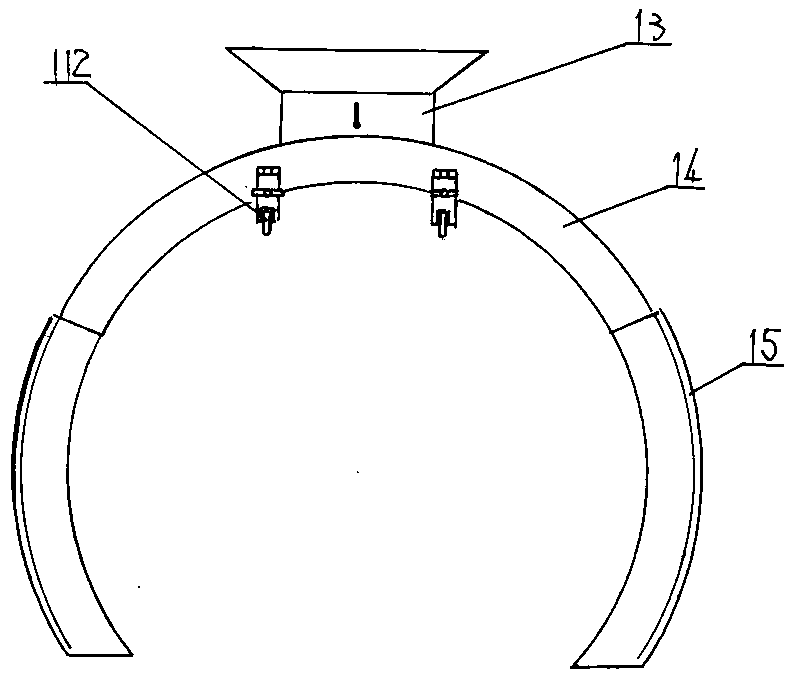

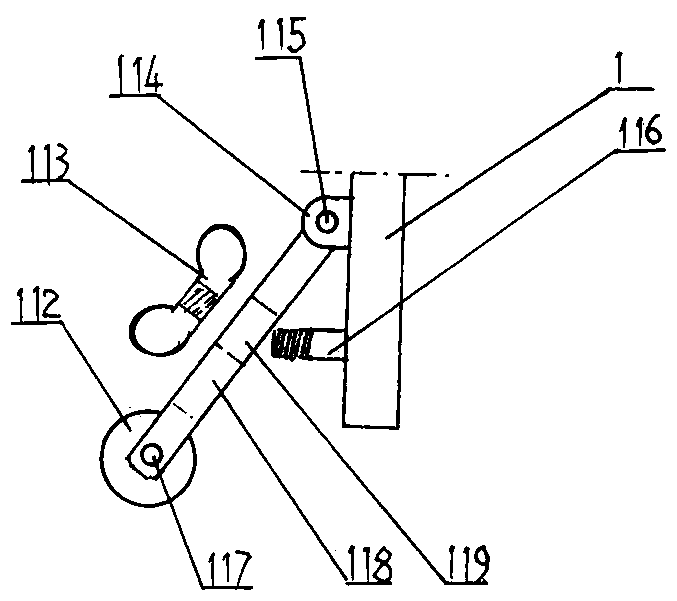

[0034] Such as Figure 1 to Figure 8 As shown, a concrete pipeline rapid encapsulation pouring device includes a concrete pipeline 4 and a fixing nut 31, wherein:

[0035] Such as figure 1 and figure 2 As shown, the upper ring formwork 1: the upper ring formwork is in the shape of a ring with an open lower end. The upper ring formwork is located at the upper end of the outer wall between the two concrete pipes connected in series. Upper ring formwork is made of ash passage 13, trapezoidal ash collection inlet 12, plate shaft 18, ash separation plate 19, left and right fixed ash separation mold roads and left and right movable ash separation mold roads.

[0036]The middle part of the upper ring formwork is the lower end of the ash passage, and the upper end of the ash passage is a trapezoidal ash collection inlet 12. The middle transverse axis of the ash passage is provided with a plate shaft 18, and the lower end of the ash separating plate 19 is fixed as one with the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com