Construction method of pile hole protective wall of manually excavated anti-slide pile

A technology of manual digging and construction methods, applied in excavation, foundation structure engineering, construction, etc., can solve the problems of weakening the slope anti-sliding ability of anti-slide piles, long exposure time of pile holes, and long construction period of pile holes, etc. Achieve the effect of reducing the workload of wet work, shortening the construction period, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

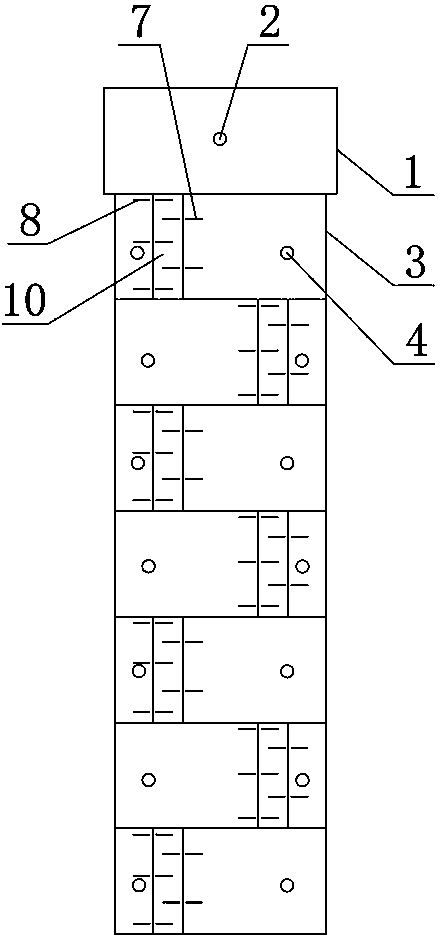

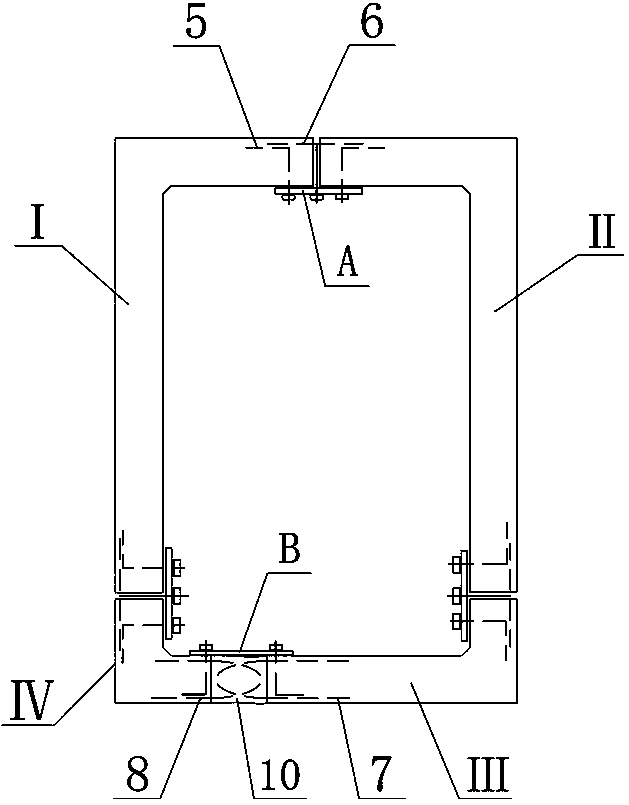

[0026] The following takes the construction of a rectangular anti-slide pile hole (the design size of the anti-slide pile is 2m×3m) whose section is 2.6m×3.6m and the size below the pile hole is 2.4m×3.4m as an example. , specifically illustrate the construction method of the manual digging anti-slide pile pile hole retaining wall, which specifically includes the following steps:

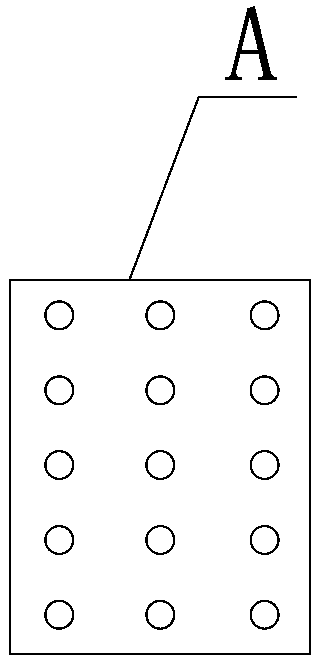

[0027] The first step is to prefabricate the top section retaining wall 1 with reinforced concrete in the prefabrication factory, its length × width × height = 3.6m × 2.6m × 1m, the wall thickness is 30cm, and a pair of lifting holes 2 are symmetrically opened on the top section retaining wall 1, To facilitate lifting and drainage;

[0028] Each wall unit is a rectangular ring structure assembled by four pieces of prefabricated parts. The four pieces of prefabricated parts include sub-batten I, sub-batten II, sub-batten III and sub-batten IV, sub-batten I and sub-batten II, which are connected head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com