Drilling speed increase tool capable of forming periodic drill string axial creeping and drilling pressure fluctuation

A periodic, drill string technology, applied in drilling equipment, driving devices for drilling in wellbore, earth-moving drilling, etc. speed and the effectiveness of WOB transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

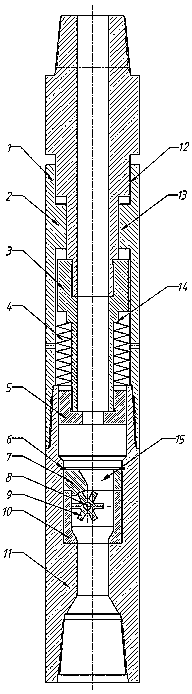

[0027] see figure 1 As shown, the drilling speed-up tool that can form periodic drill string axial creep and WOB fluctuations includes an upper joint 1, a casing 2, and a lower joint 11;

[0028] The upper joint 1 is set on the upper end of the shell 2, the upper joint 1 is used to connect with the upper drill string, and the lower joint 11 is threadedly connected to the lower end of the shell 2, wherein the cavity of the shell 2 is provided with a stepped shaft 3, and the lower joint The upper end in the cavity of 11 is connected with the bearing ring 5 in sliding seal.

[0029] The upper end of the stepped shaft 3 is threadedly connected to the lower end of the upper joint 1, and the lower end of the stepped shaft 3 is threadedly connected to the pressure ring 5, and the upper joint 1, the stepped shaft 3, the pressure ring 5 and the lower joint 11 form a connected flow channel .

[0030] The middle part of the outer periphery of the step shaft 3 is covered with a disc spr...

Embodiment 2

[0048] This embodiment is optimized on the basis of embodiment 1, specifically:

[0049] see figure 1 As shown, the inner diameter of the upper limit step 13 of the housing 2 is smaller than the diameter of the upper end of the stepped shaft 3;

[0050] The inner diameter of the upper limit step 13 of the housing 2 is smaller than the diameter of the middle part of the upper joint 1 .

[0051] The axial movement of the step shaft 3 and the upper joint 1 is limited by the limit step 13. On the one hand, a step fit is formed to effectively prevent the bottom hole drill bit connected to the lower end from falling, and on the other hand, it can prevent excessive WOB in the upper part. Disc spring group 4 is crushed, thereby can play a protective role.

Embodiment 3

[0053] This embodiment is optimized on the basis of embodiment 1, specifically

[0054] see figure 1 As shown, the eccentric flow channel 15 on the impeller guide sleeve 7 is closed;

[0055] By designing the eccentric flow channel 15 into a closed structure, the drilling circulating medium can be gradually supercharged after flowing through the eccentric flow channel 15 of the impeller guide sleeve 7, and the pressurized drilling circulating medium has a greater impact force The driving impeller 9 forms stronger pulses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com