Hot-swap system and method for on-site testing of bus function modules

A field test, functional module technology, applied in general control systems, control/regulation systems, simulators, etc., can solve the problems of not fully meeting requirements, waste of resources, and high costs, to achieve protection, solve thermal shock problems, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

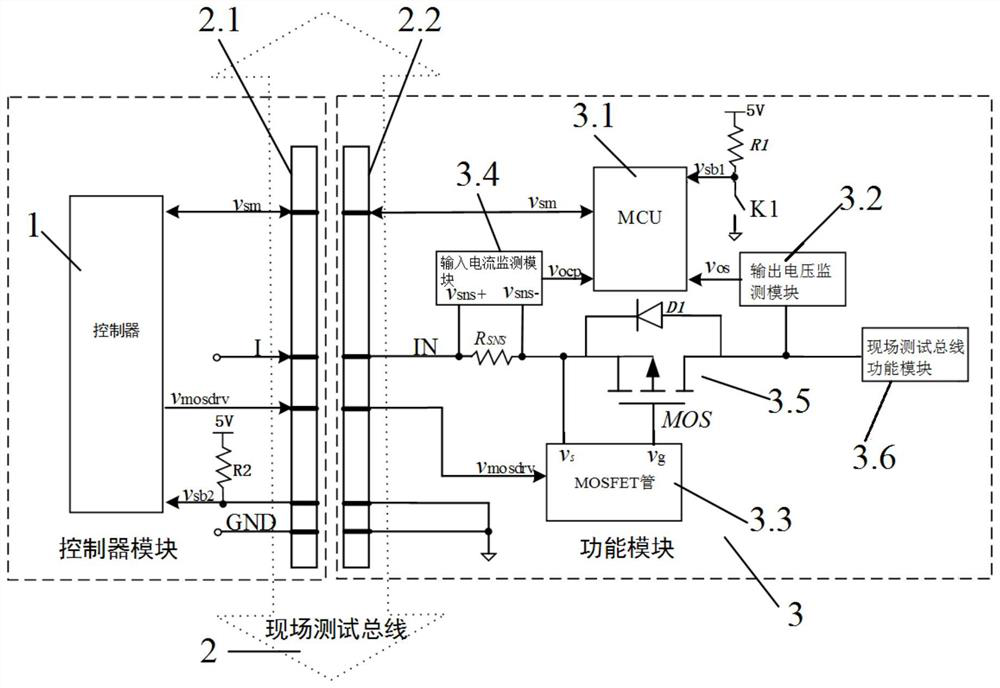

[0031] Such as figure 1 Shown is a kind of hot-swappable system that is used for field test bus functional module, and it comprises controller 1 (controller 1 is made of single-chip microcomputer system) and the hot-swappable unit 3 of field test bus functional module, described field test bus The hot-swappable unit 3 of the functional module includes an MCU 3.1, an output voltage monitoring module 3.2, a MOSFET driver module 3.3, an input current monitoring module 3.4 and a MOSFET tube 3.5, and the controller 1 is used to connect the controller 1 and the Status monitoring line v between MCU3.1 sm , so that the MCU3.1 access state information communication and MCU3.1 identity identification are performed between the controller 1 and the MCU3.1;

[0032] The controller 1 is also used to transmit a control signal for switching on the MOSFET to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com