Evaporative cooling system of rail transit traction equipment and rail transit traction equipment

A traction equipment and rail transit technology, applied in the field of rail transit, can solve the problems of increasing the complexity of the heat dissipation system, affecting the life of the insulation layer, and being unable to fully heat up, reducing pipeline layout, ensuring timely maintenance, and reducing volume and weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

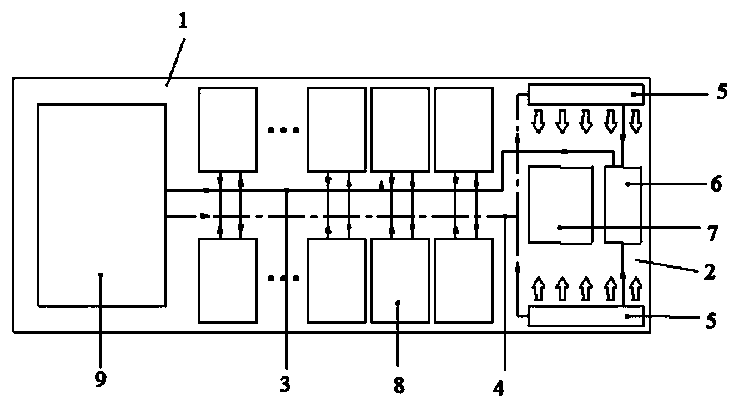

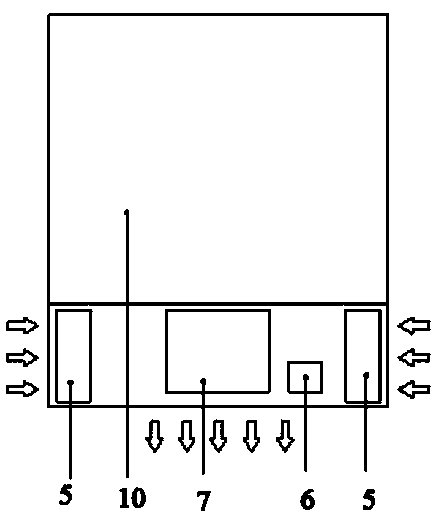

[0028] Such as figure 1 with figure 2 As shown, the evaporative cooling system of rail transit traction equipment in this embodiment includes a water cooling chamber 1, an air cooling chamber 2 and a liquid cooling circuit. , the main water outlet pipe 4 and the heat exchanger, the main water inlet pipe 3 and the main water outlet pipe 4 are located in the middle of the water cooling chamber 1 and arranged along the length direction of the water cooling chamber 1, separating the water cooling chamber 1 into left and right parts for installation of rail transit traction Each power module 8 of the converter in the equipment, in which the main water inlet pipe 3 and the main water outlet pipe 4 are connected to the water cooling plate of each power module 8, so as to evaporate and dissipate heat to each power module 8 (such as spraying the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com