heat sink

A radiator and heat sink technology, which is applied in indirect heat exchangers, heat exchange equipment, electric solid devices, etc., can solve the problems such as the inability to fully uniformize the heating of the heat pipe group, the inability to fully improve the cooling characteristics, and the inability to exert the cooling characteristics. Achieves the effect of improving the cooling performance, preventing the increase of the size of the radiator, and improving the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

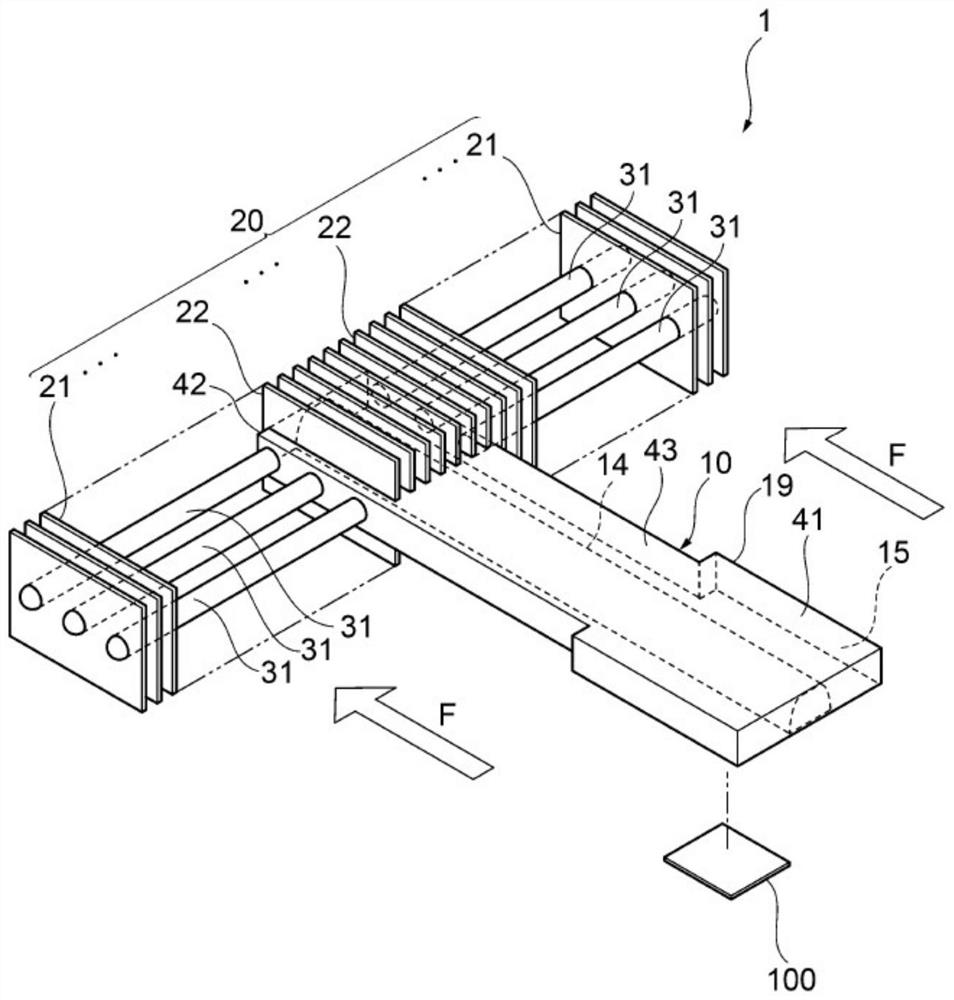

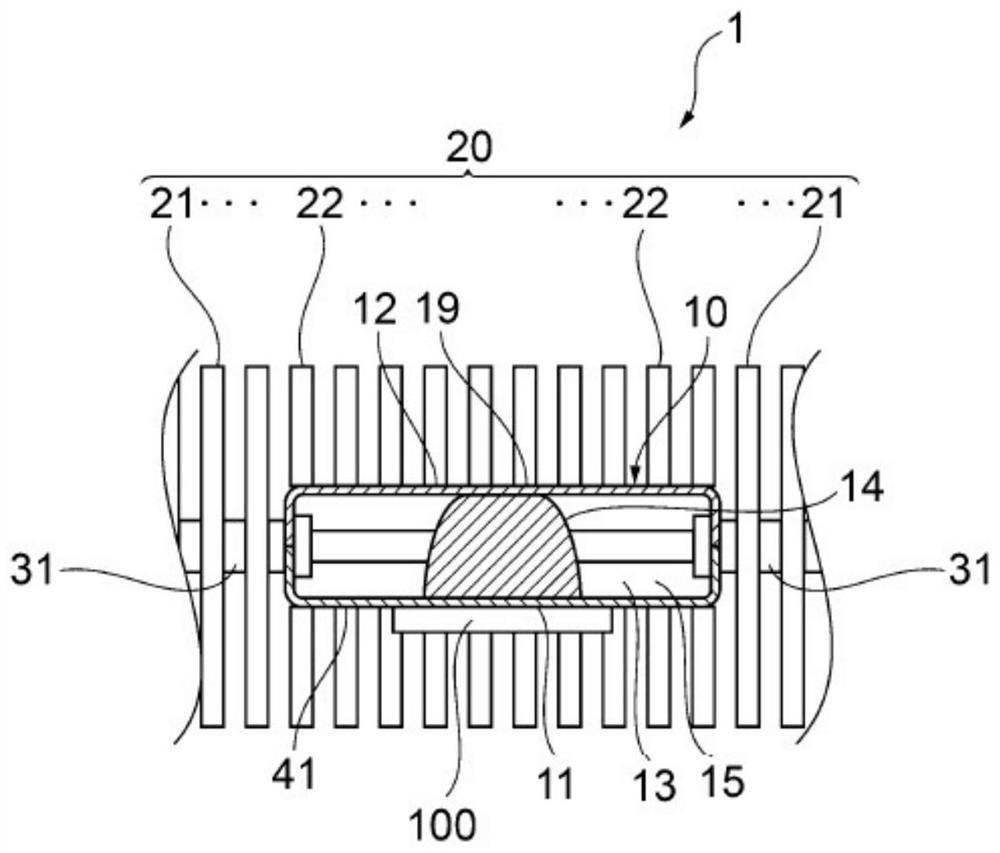

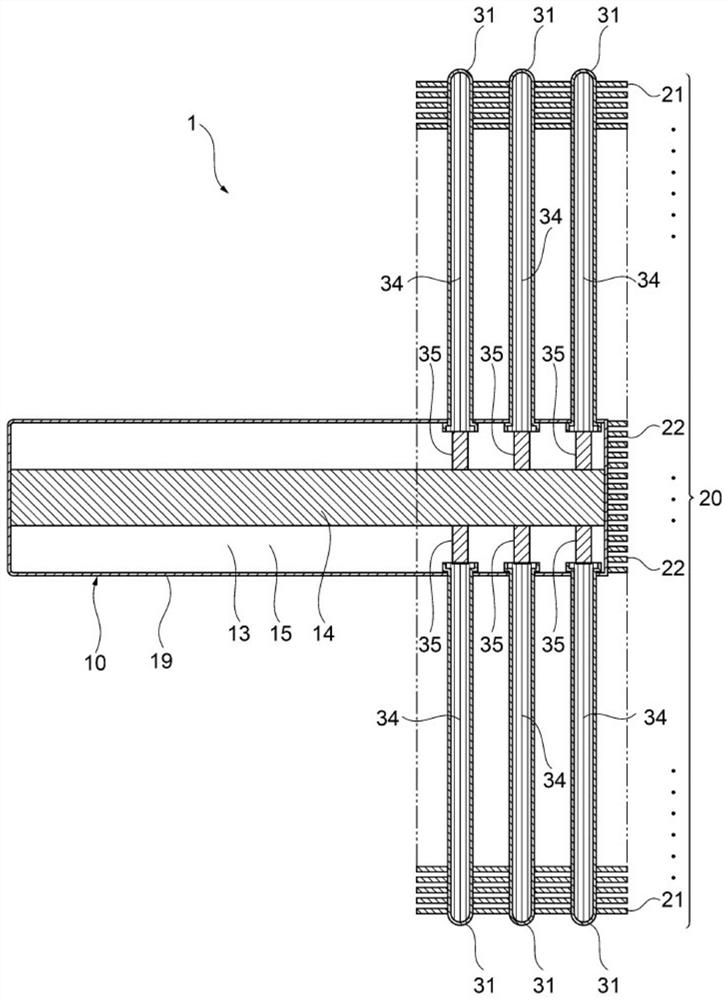

[0049] Hereinafter, a heat sink according to an embodiment example of the present invention will be described with reference to the drawings. figure 1 It is a schematic perspective view explaining the heat sink concerning the Example of this invention. figure 2 It is a schematic sectional view explaining the heat sink concerning the Example of this invention. image 3 It is a schematic explanatory drawing which shows the connection part of the heat-transfer member and a pipe body of the radiator concerning the Example of this invention. Figure 4 It is a schematic perspective view explaining the heat sink concerning the 2nd Embodiment of this invention. Figure 5 is a schematic plan view illustrating a heat sink according to a second embodiment of the present invention. Figure 6 is a schematic front view illustrating a heat sink according to a second embodiment of the present invention. Figure 7 is a schematic perspective view illustrating a heat sink according to a thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com