Haw coring and stringing device for preparing sugar-coated haws on a stick

A technology of candied haws and hawthorn, which is applied to fruit pitting devices, transmission devices, confectionery, etc. It can solve the problems of high labor intensity, easy to stab hands, and low production efficiency, achieve efficient cycle operations, reduce manpower input, and improve production efficiency. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

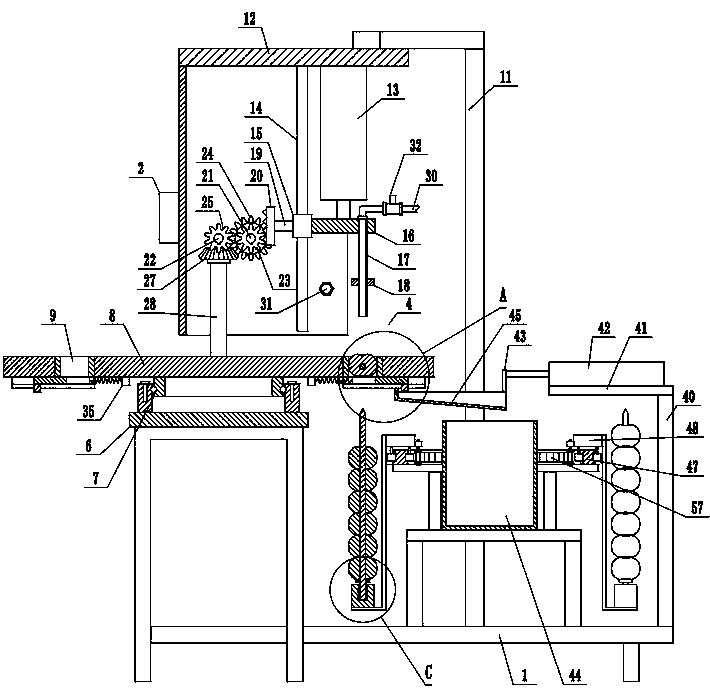

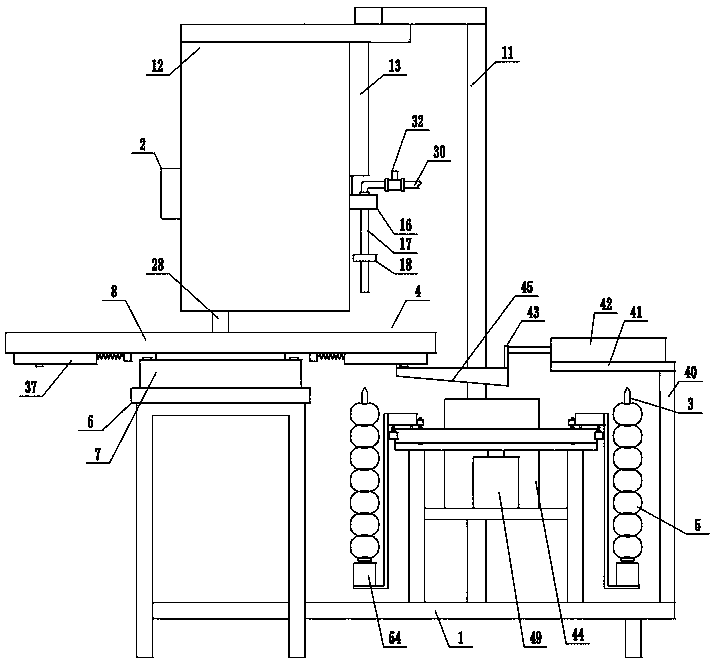

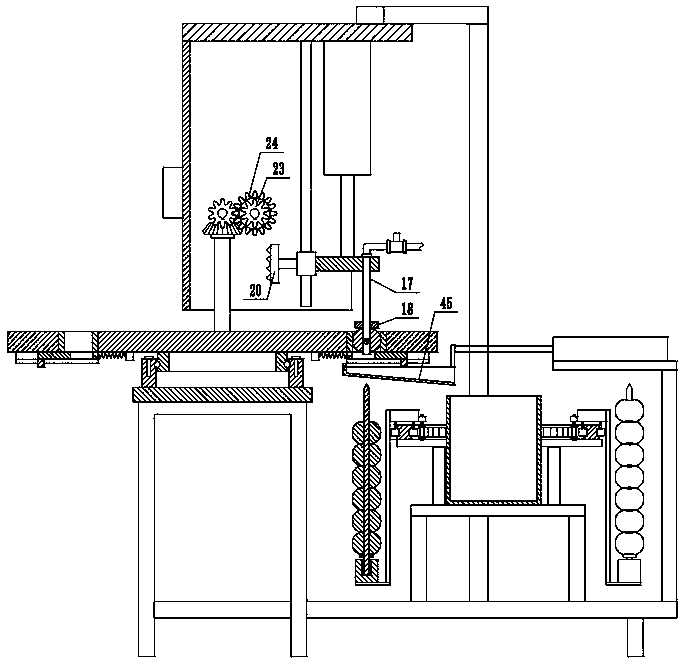

[0031] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-12Shown: a kind of hawthorn depitted bunching device that is used for making candied haws, comprises frame 1, controller 2 and candied haws stick 3, has denuclearing station 4 on the frame 1, is provided with for candied haws Pick 3 transports to the conveying mechanism of denucleating station 4 one by one, is used for the turntable mechanism that hawthorn 5 is transported to denucleating station 4 one by one and carries out denucleating mechanism to the hawthorn 5 that is in denucleating station 4 places, The enucleating mechanism drives the turntable mechanism to move intermittently through the transmission mechanism; the turntable mechanism includes a horizontal plate 6, a turntable bearing 7 and a rotating disk 8, the horizontal plate 6 is horizontally installed on the frame 1, and the rotating disk 8 is rotatably installed on the horizontal plate through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com