Fibrous facial mask, fibrous facial mask processing device and method

A processing device and facial mask technology, which is applied in the field of fiber mask and fiber mask processing device, can solve the problems such as the inability to quantitatively add essence, and achieve the effect of occupying a small space and improving moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

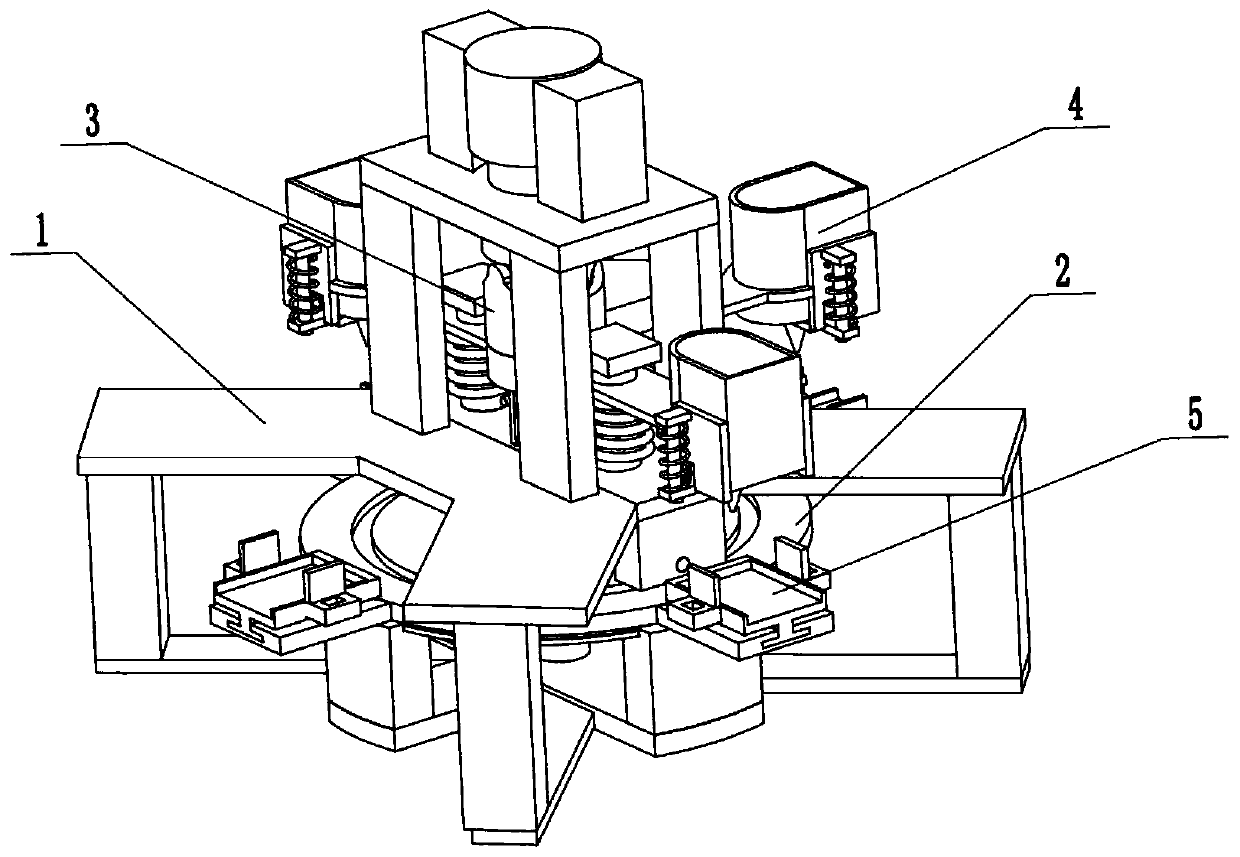

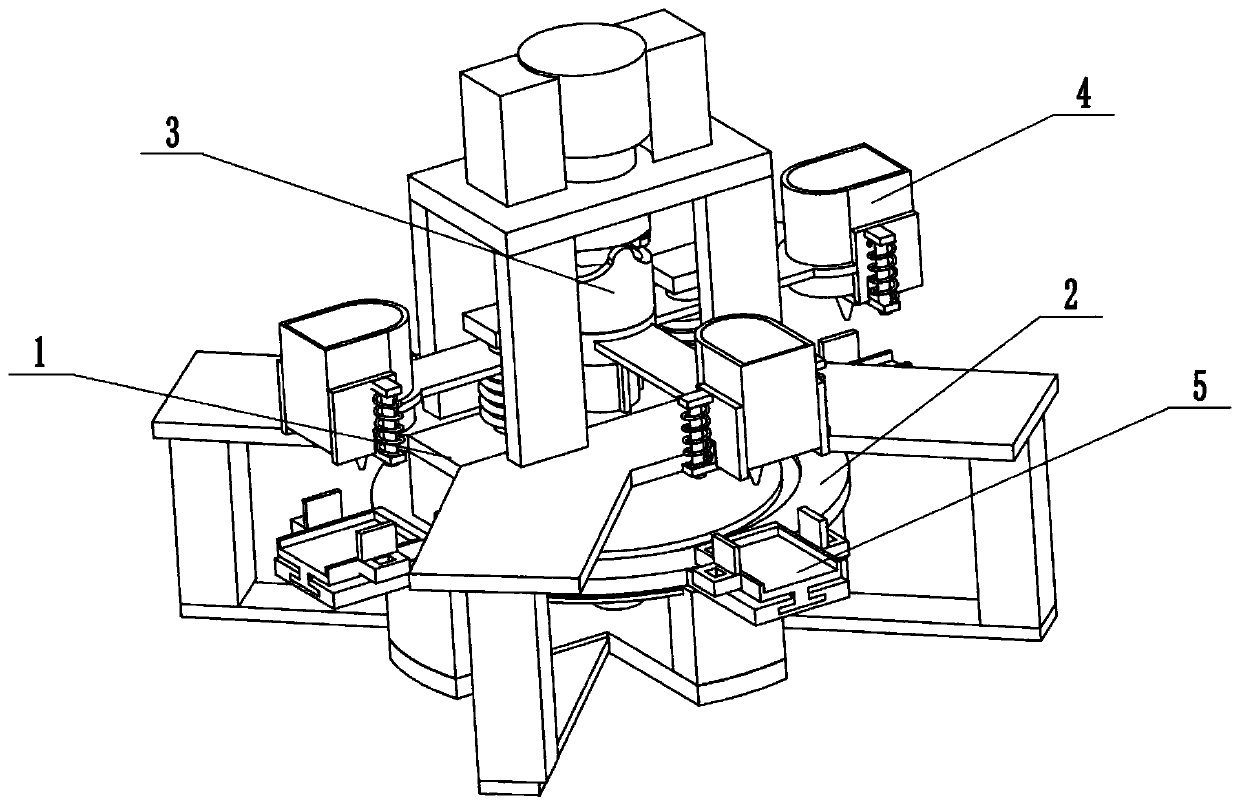

[0036] Such as Figure 1 to Figure 13 Shown, a kind of fiber facial mask processing device comprises fixed sliding base 1, intermittent rotary driver 2, advances adder 3, three stoste adders 4 and four fiber facial mask are carrier 5, the intermittent rotary driver 2 The lower end is fixedly connected to the fixed sliding base 1, the upper end of the intermittent rotary driver 2 is slidably connected to the intermittent rotary driver 2, the propulsion adder 3 is slidably connected to the middle end of the fixed sliding base 1, and the three stock solution adders 4 are all fixedly connected to the Propel the adder 3, and the four fiber facial masks are evenly slidably connected on the fixed sliding base 1 in the carrier 5. The fiber mask that needs to be added with essence is intermittently transported to the intermittent rotary drive 2 through the fiber mask carrier 5, and the three stock solution adders 4 are sequentially added with sake yeast essence, arbutin essence and vit...

specific Embodiment approach 2

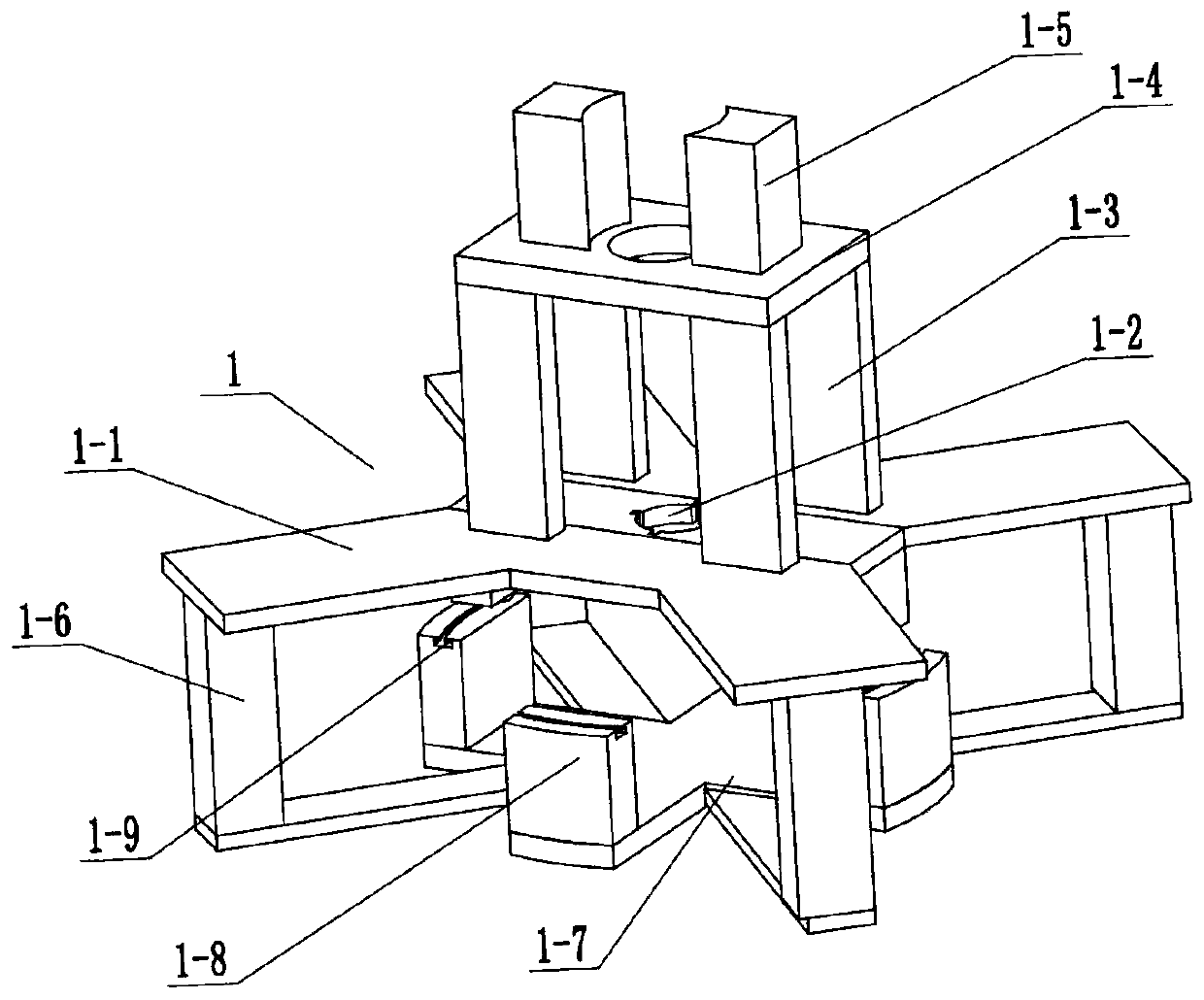

[0038] Such as Figure 1 to Figure 13 As shown, this embodiment will further describe Embodiment 1. The fixed sliding base 1 includes a central connecting plate 1-1, a central limiting chute 1-2, four upper connecting plates 1-3, and an upper fixing plate 1 -4, two motor fixing seats 1-5, four lower connecting plates 1-6, base plate 1-7, four chute seats 1-8, four arc-shaped T-shaped chute 1-9, two pulleys Seat 1-10, two pulley grooves 1-11 and two pulleys 1-12, the middle end of the center connection plate 1-1 and the center limit chute 1-2 that runs through up and down, four upper connection plates 1-3 Evenly and fixedly connected to the upper end of the central connecting plate 1-1, the upper fixing plate 1-4 is fixedly connected to the four upper connecting plates 1-3, and the two motor fixing seats 1-5 are fixedly connected to the upper fixing plate 1-4 The upper end of the central connecting plate 1-1 is uniformly fixedly connected to four lower connecting plates 1-6, a...

specific Embodiment approach 3

[0040] Such as Figure 1 to Figure 13 As shown, this embodiment will further illustrate the second embodiment. The intermittent rotation driver 2 includes a lower servo motor 2-1, a double fan drive gear 2-2, a central drive gear 2-3, a central shaft 2-4, Sliding turntable 2-5, T-shaped ring slider 2-6, four loaded sliding seats 2-7, four T-shaped chute 2-8 and pulley sliding groove 2-9, the lower servo motor 2-1 is fixed Connected to the base plate 1-7, the double fan drive gear 2-2 is fixedly connected to the transmission shaft of the lower servo motor 2-1, the double fan drive gear 2-2 is meshed with the central drive gear 2-3 for transmission, and the central drive gear 2-3 is fixedly connected to the central rotating shaft 2-4, the lower end of the central rotating shaft 2-4 is rotatably connected to the middle end of the base plate 1-7, the sliding turntable 2-5 is fixedly connected to the upper end of the central rotating shaft 2-4, and the sliding turntable The lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com