Internal material returning guniting granulator

The technology of shotcrete granulator and granulator is applied in the direction of organic fertilizer, sewage/sludge fertilizer, solid/semi-solid fertilizer, etc. Achieve the effect of less equipment, reduced investment and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

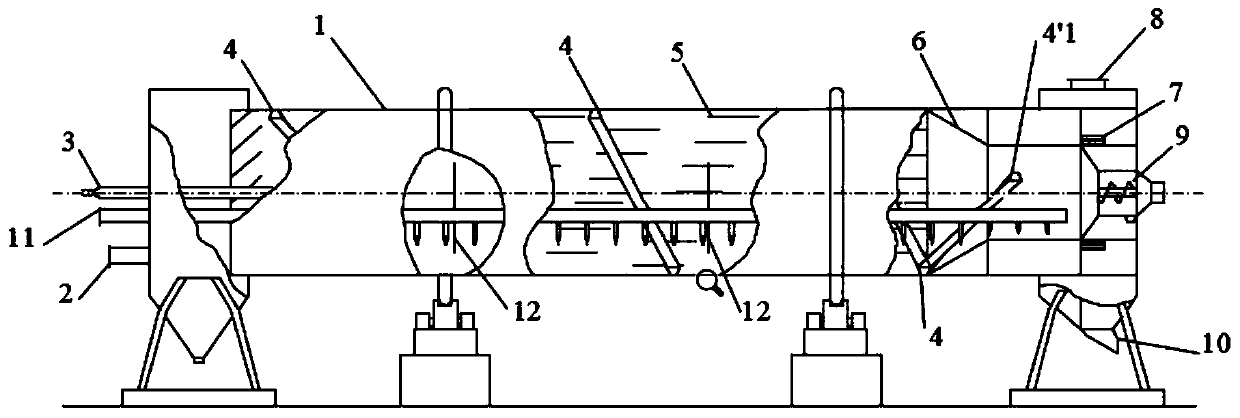

[0019] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

[0020] like figure 1 As shown, an internal material-returning slurry granulator includes a granulator drum 1, the head of the drum 1 is provided with an air inlet 2 and a spray gun 3, and the granulator drum 1 includes a granulation section, a drying Section and sieve section, the granulation section and the drying section are provided with a copying plate 5 and a main return screw 4, the drying section is provided with an electric heating net 12, and the sieve section is provided with a grading cone 6 and a trommel 7. The cone 6 is a screen structure and the large opening end of the grading cone 6 is connected to the drying section, and the small opening end is connected to the trommel 7. The inner wall of the sieve section is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com