Straight wire drawing device

A straight-forward, wire-drawing technology, applied in wire-drawing dies and other directions, can solve the problems of increasing production costs and burdens, achieving good stretching effect, expanding applicable area, and reducing production costs and burdens on enterprises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

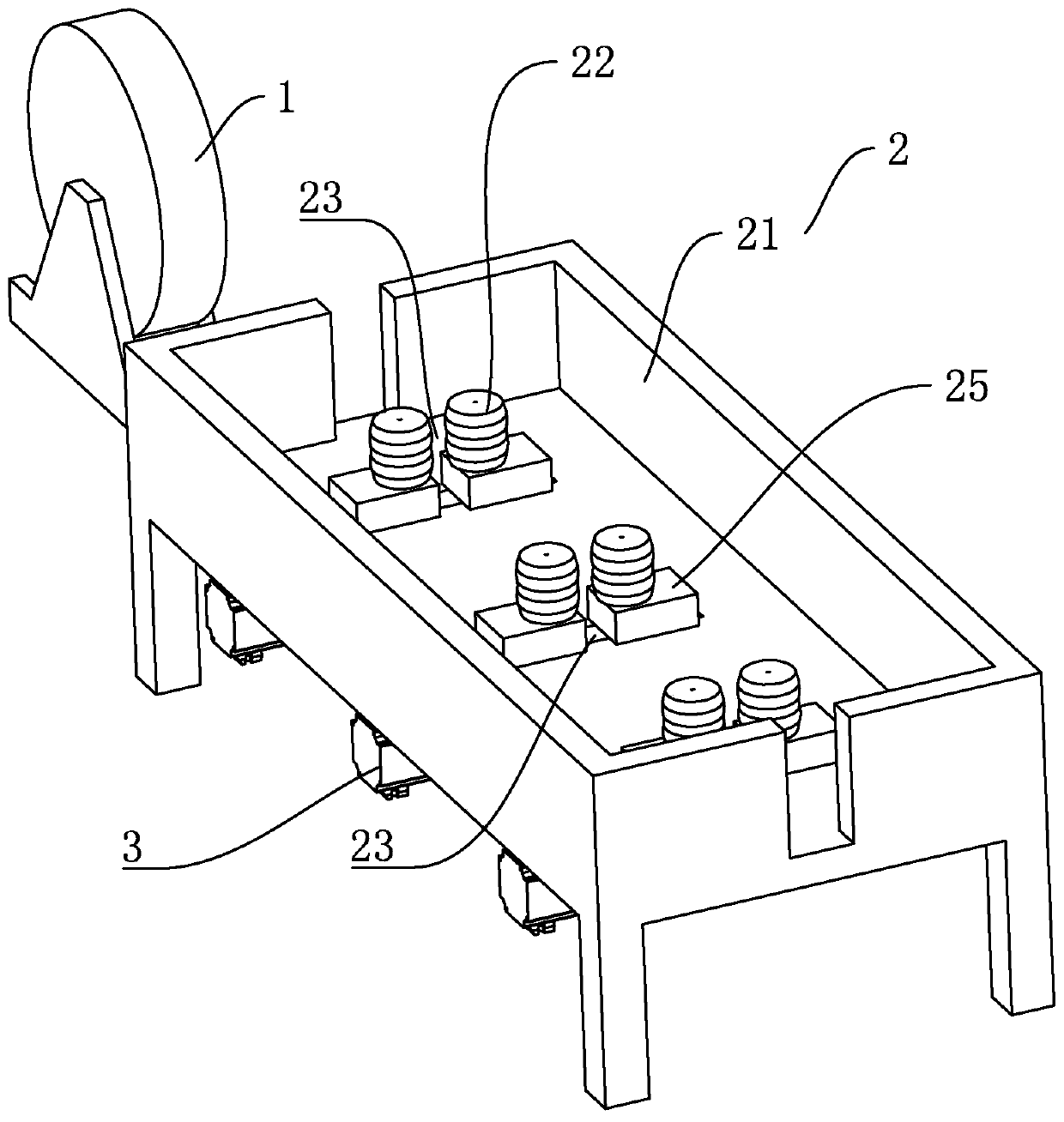

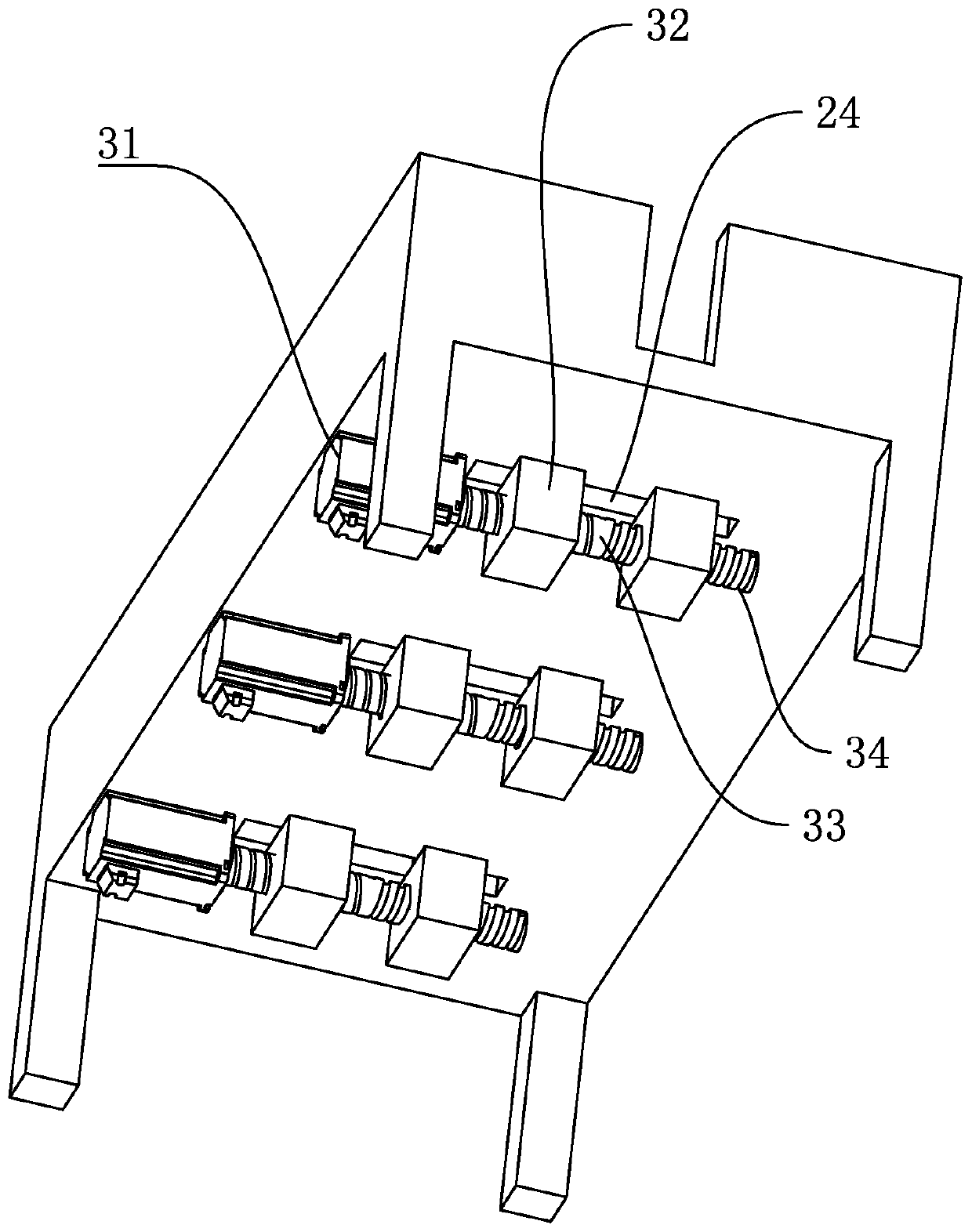

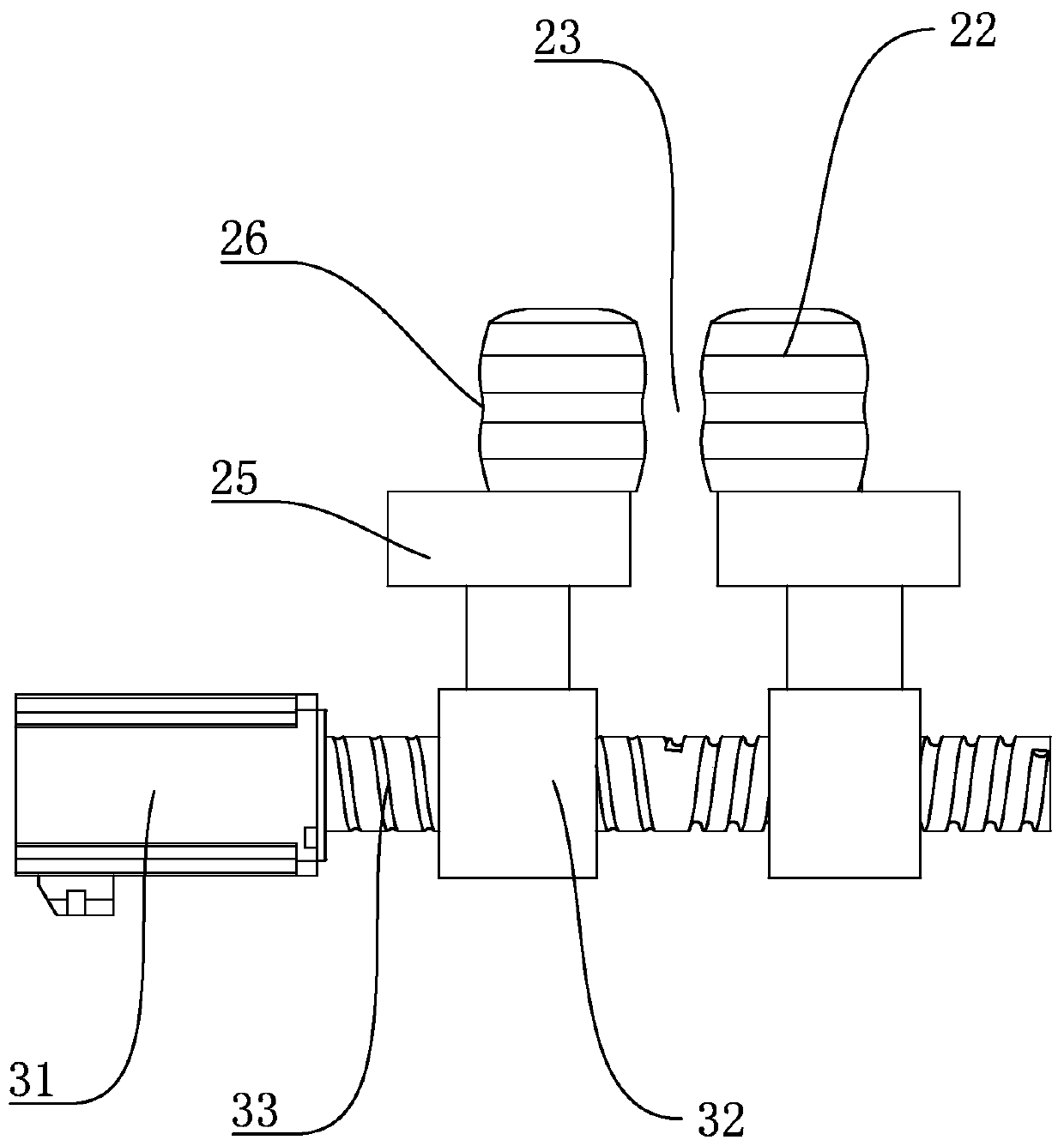

[0031] Embodiment 2, a kind of straight wire drawing equipment, structure such as figure 1 with Figure 4 As shown, the difference from Embodiment 1 is that the drive mechanism 3 includes a drive rack 35, one movable block 25 is fixedly connected to the housing 21, and the other movable block 25 is slidably connected in the parallel chute 24, and extends To the bottom of the housing 21 , the driving rack 35 is fixed on the movable block 25 , and the bottom of the housing 21 is rotatably connected with a driving gear 36 through a rotating shaft, and the driving rack 35 and the driving gear 36 mesh with each other.

[0032] Driving mechanism 3 also comprises driving worm gear 37, and driving worm gear 37 is fixed with the coaxial center of rotating shaft, and is connected with driving worm screw 38 in rotation on casing 21, and driving worm screw 38 and driving worm gear 37 mesh with each other, and casing 21 is also provided with driving motor 39, and driving The output shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com