Roll bending forming method and device for straight edges of to-be-welded pipe

A technology of roll forming and pipe material, which is applied in the field of steel pipe processing, can solve the problems of easy shifting of steel pipe center of gravity, uneven groove, low forming efficiency, etc., achieve stable and reliable manufacturing process, improve process stability, and improve forming quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A continuous roll bending forming method for the straight edge of the edge of the pipe to be welded, comprising the following steps:

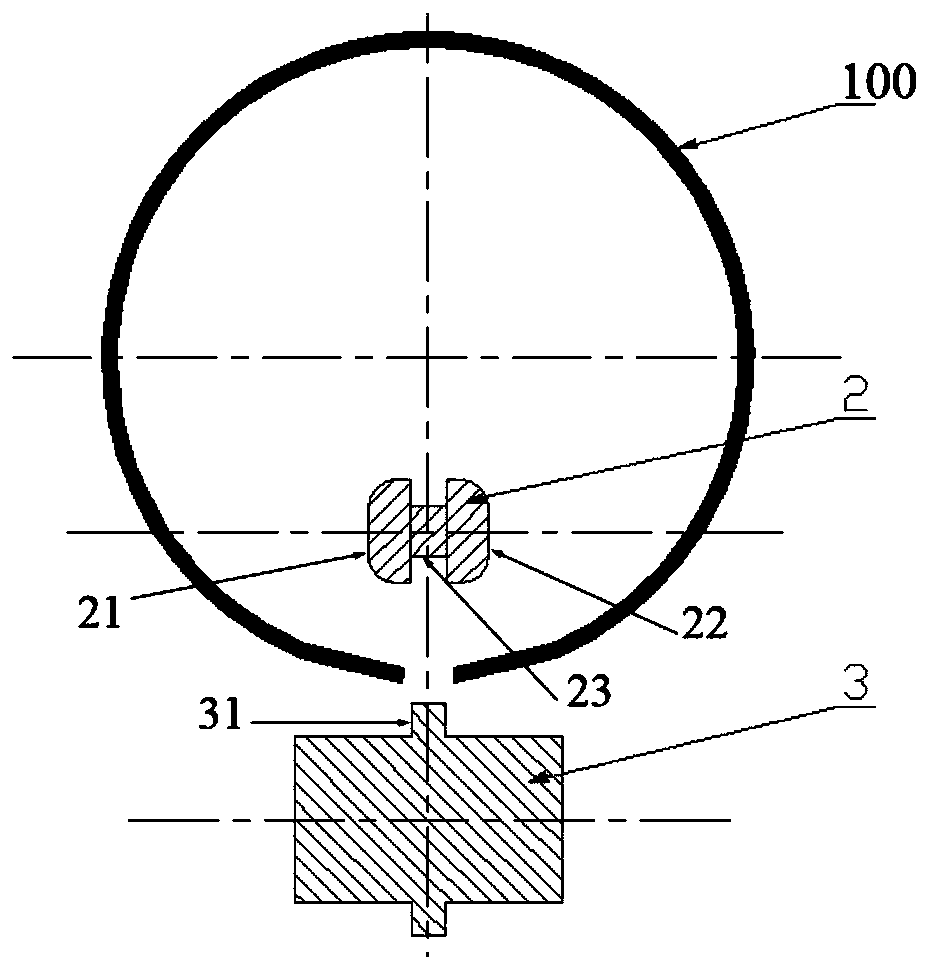

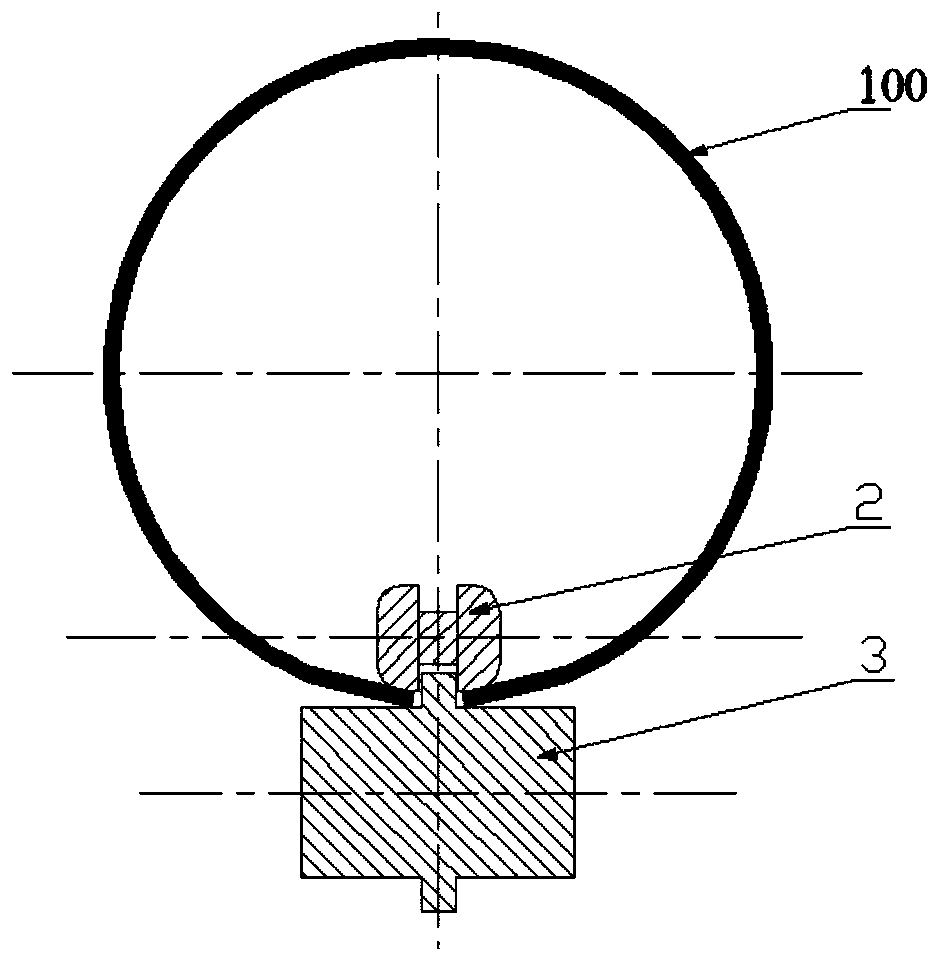

[0048] 1) if figure 1 and figure 2 As shown, after the coiled tube 100 with straight sides is transferred to the importing mold mechanism, the coiled tube 100 is placed on the lower importing die 3 , and the boss 31 on the surface of the lower importing die 3 is inserted between the two straight edges of the coiling tube 100 , the upper import mold 2 is fixed on the inner side of the roll tube 100 by the mold frame. The lower introduction mold 3 rises firstly, abuts against the straight edge of the roll tube 100 from the outer surface of the roll tube 100 and approaches the upper introduction mold 2 . Due to the extruding effect of the forming blocks 21, 22 of the upper leading die and the lower leading die 3, the straight edge of the roll tube 100 is preformed.

[0049] At the same time, the motor drives the lead-in mold 3 to rotate...

Embodiment 2

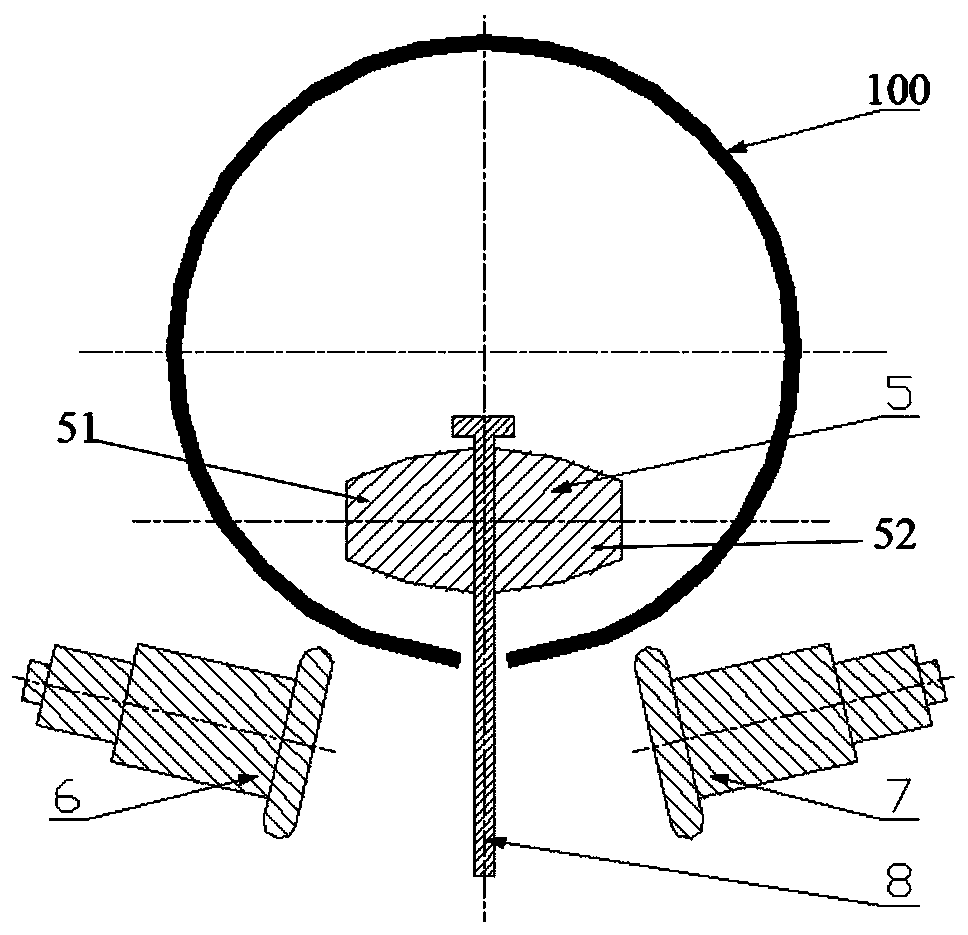

[0057] This embodiment provides a roll-bending method for straight edges of pipes with different diameters to be welded. According to the external dimensions required by pipe products with different diameters, the trajectory of the left-down roll-bending die 6 and the right-down roll-bending die 7 is adjusted so that The lower left roll bending die 6 and the lower right roll bending die 7 move back and forth along the circumferential direction of the coiled pipe edge, thereby realizing the manufacture of pipes to be welded without straight edges of different diameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com