Flexible switching system layout structure for vehicle welding

A technology of switching systems and layout structures, applied in welding/cutting auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problem of inability to produce multiple models at the same time, and achieve the goal of shortening the renovation period, reducing production costs and high productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

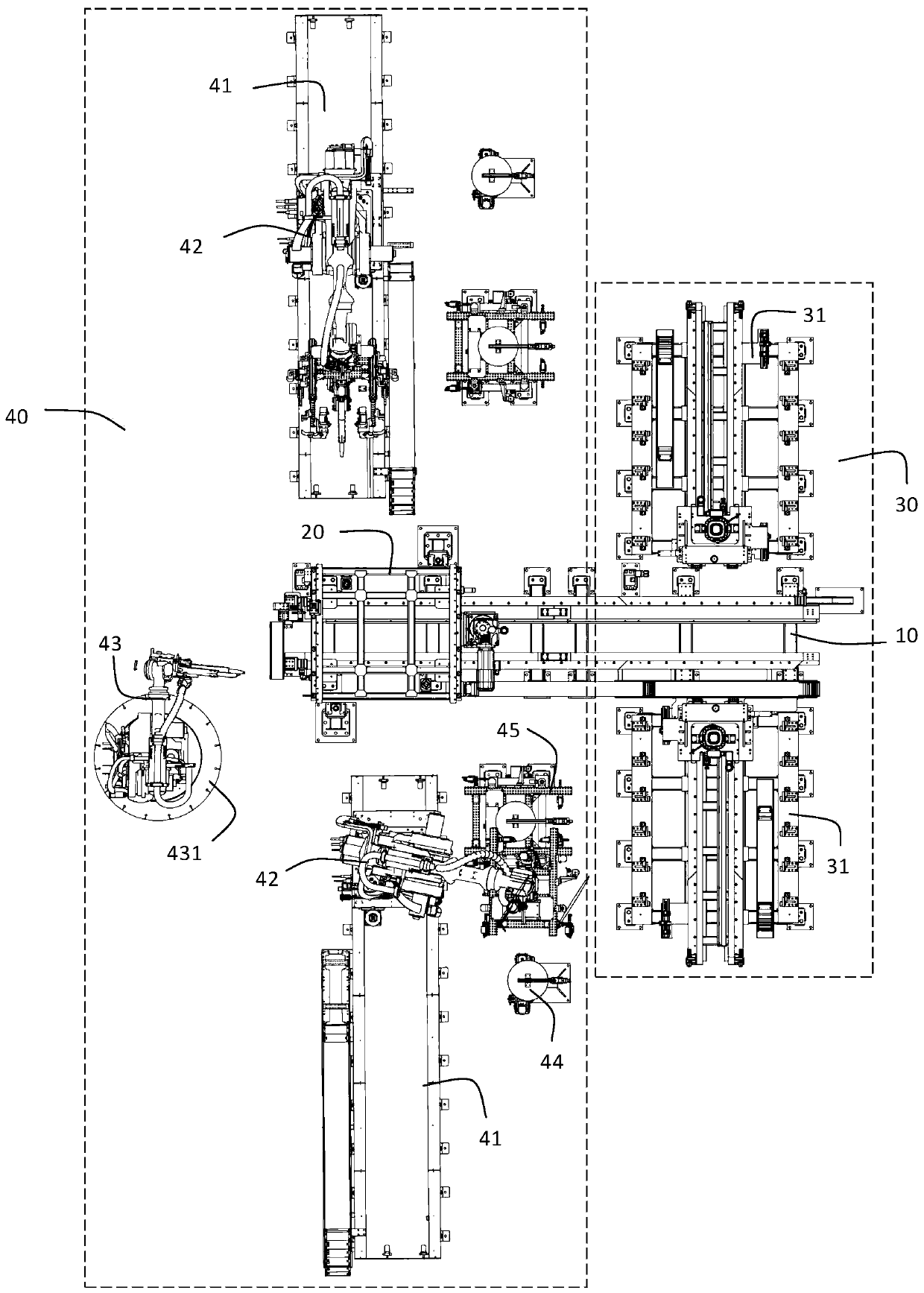

[0089] Such as figure 1 Shown is the layout structure of the flexible switching system for automobile welding of the present invention, including: a linear sliding table 10 , a trolley mechanism 20 , a vehicle type switching area 30 and a welding transfer area 40 .

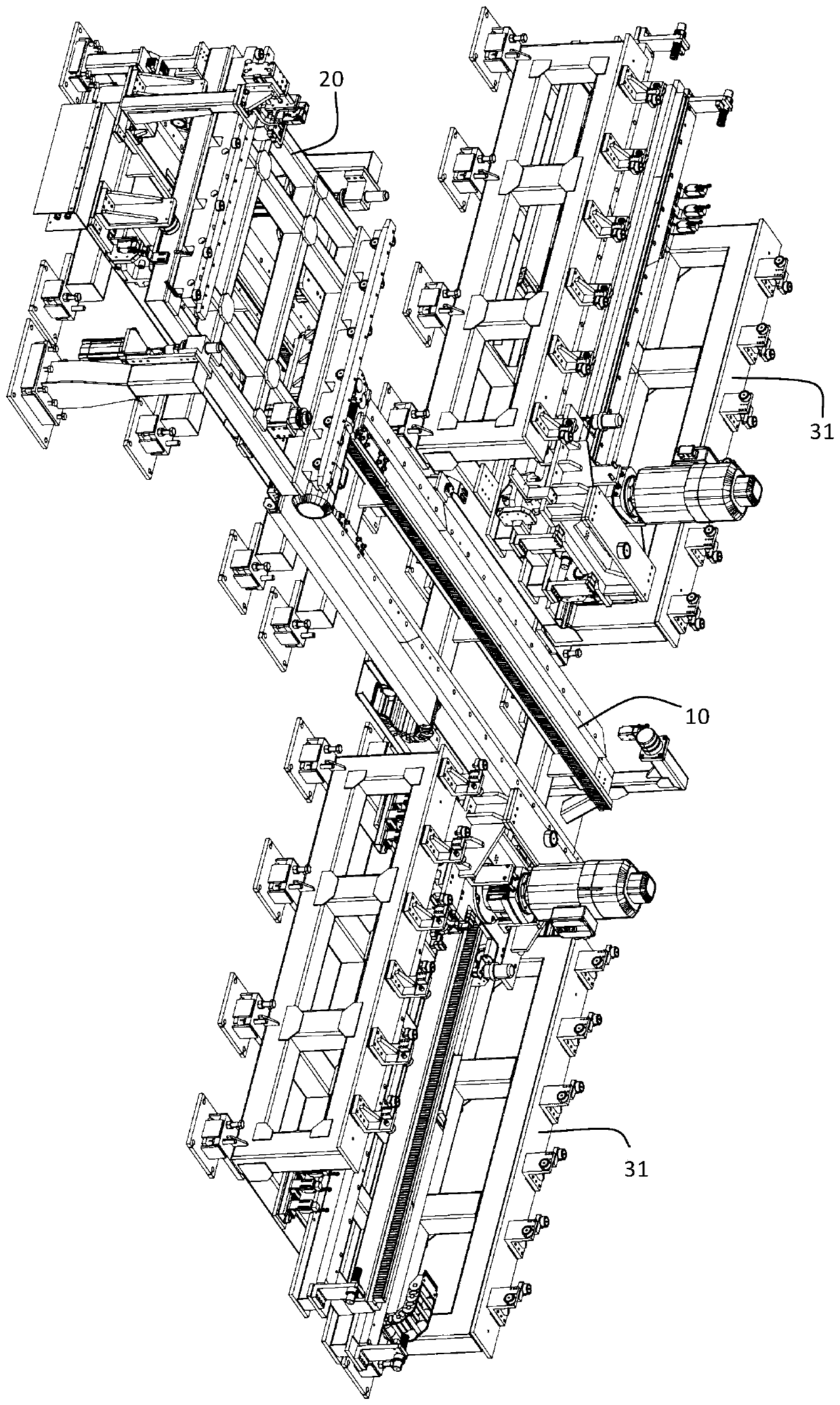

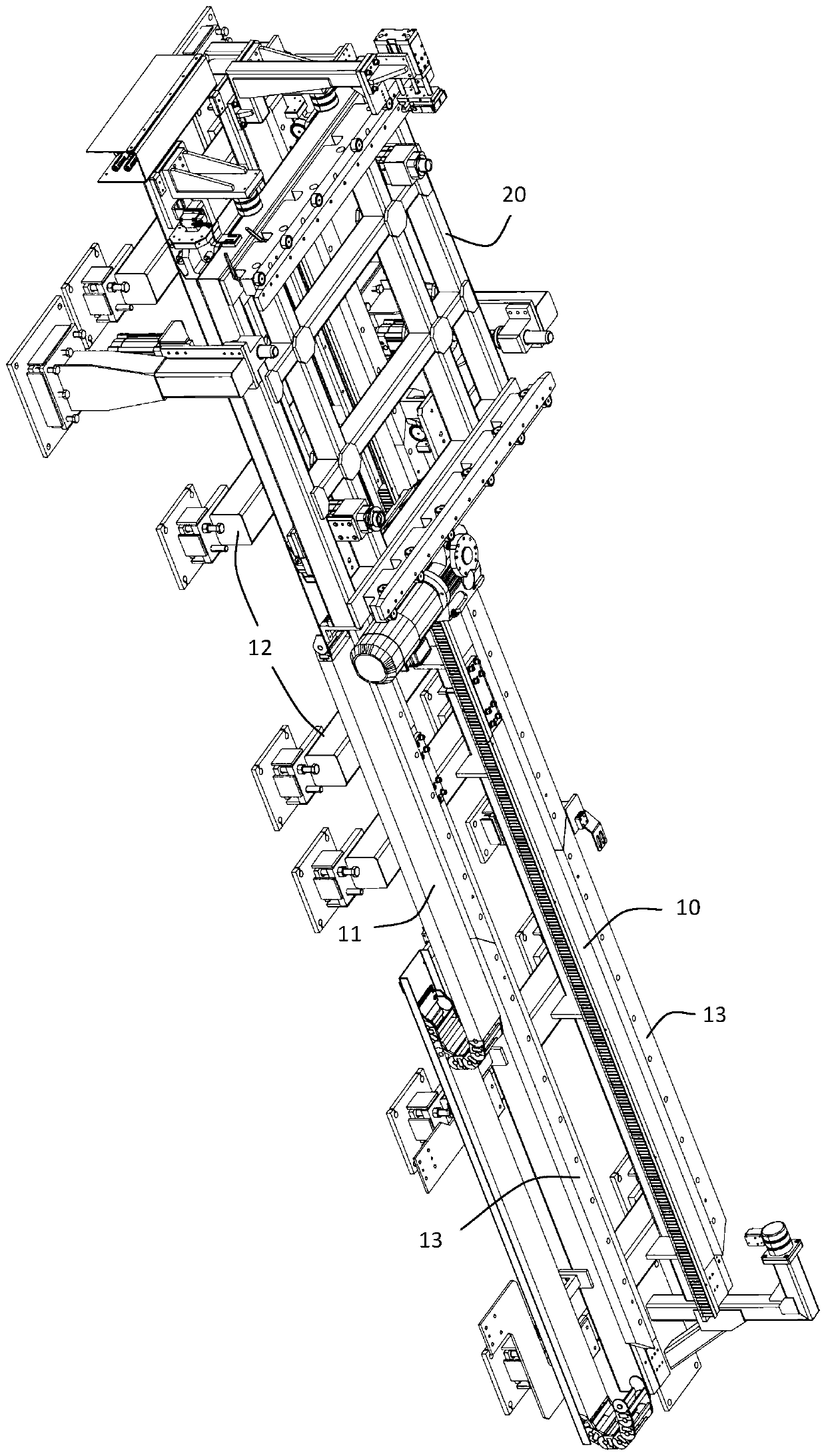

[0090] Such as Figure 2~3 As shown, the linear slide table 10 has: two parallel bottom beams 11; several sleepers 12 are arranged in parallel and at intervals, and the bottom beams 11 are fixed on the sleepers 12; Sliding is provided with trolley mechanism 20. The trolley mechanism 20 can shuttle and slide back and forth between the station opposite to the fixture warehouse 31 of the vehicle type switching area 30 and the station opposite to the welding transfer area 40 on the slide rail 13 of the slide table 10 .

[0091] Such as Figure 4 As shown, the vehicle type switching area 30 has two fixture warehouses 31, which are arranged on both sides of one end of the slide table 10, and the center line of the fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap