Method for preparing 9 beta, 10 alpha-dehydroprogesterone diethyl diketal by utilizing LED light source

A technology of ketone diethylene ketal and LED light source, which is applied in the direction of ketal steroids, chemical instruments and methods, steroids, etc., can solve the problems of complex photochemical reaction products and difficult processes, and achieve important economic and social values. The effect of less control points and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

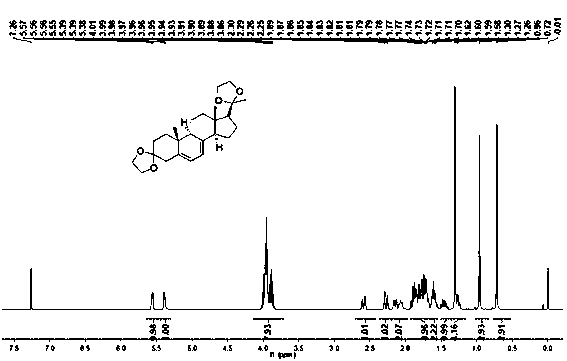

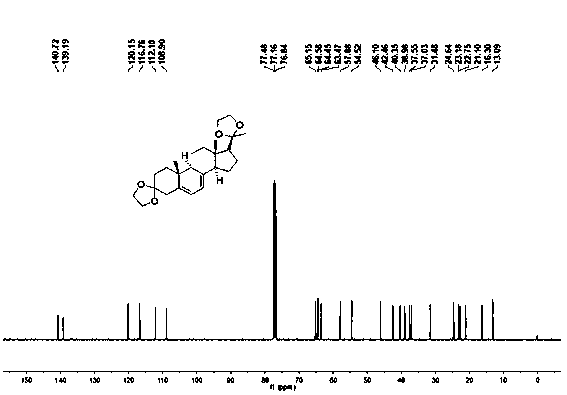

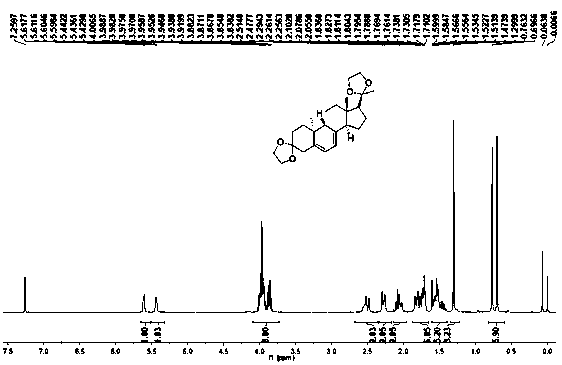

Image

Examples

Embodiment 1

[0043] Dissolve 10 grams of the raw material 9α, 10β-dehydroprogesterone diethylenediketal in 1 L of reaction solvent methanol, place it in the feeding tank and cool it to -30°C, protect it with argon, open the first photochemical reactor, the second Two photochemical reactors and condensing systems. The photochemical ring-opening reaction is carried out in the first photochemical reactor, and the photochemical ring-closing reaction is carried out in the second photochemical reactor. The wavelength of the LED light source in the first photochemical reactor is 270 nanometers, and the second photochemical The wavelength of the LED light source in the reactor is 330 nanometers, then the flowmeter is turned on, and the reaction temperature is controlled at -30±5°C.

[0044] The raw material solution passes through the first photochemical reactor to obtain a solution after the ring-opening reaction, and then directly enters the second photochemical reactor to obtain a solution conta...

Embodiment 2

[0047] Reaction temperature is controlled at-15 ± 5 ℃, and other conditions are with embodiment 1.

[0048] The reaction time is about 4 hours, and the HPLC test results show that the content of the raw material 9α, 10β-dhydroprogesterone diethylene ketal in the crude product is about 30%, and the content of the target product 9β, 10α-dhydroprogesterone diethylene ketal About 62%, other impurity content about 8%.

Embodiment 3

[0050] Reaction temperature is controlled at 0 ± 5 ℃, and other conditions are with embodiment 1.

[0051] The reaction time is about 3.5 hours, and the HPLC test results show that the content of the raw material 9α, 10β-dehydroprogesterone diethylene ketal in the crude product is about 38%, and the content of the target product 9β, 10α-dehydroprogesterone diethylene ketal About 56%, other impurity content about 6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com