Additive for electrotinning process of methylsulphonic acid method

A technology of methanesulfonic acid method and electroplating tin, which is applied in the field of additives and can solve problems such as difficult process procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

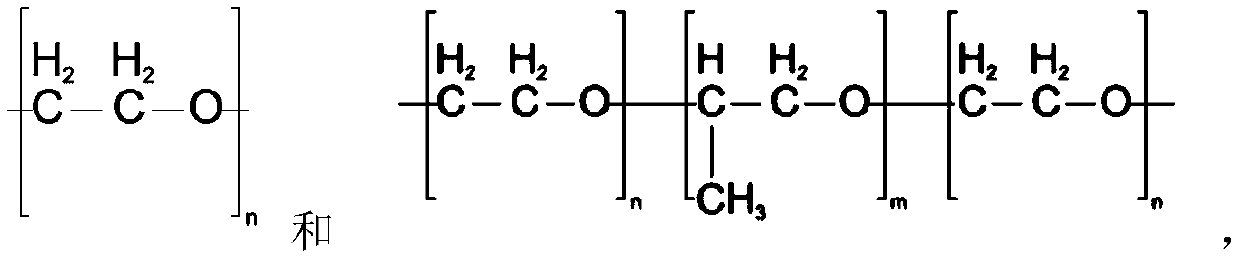

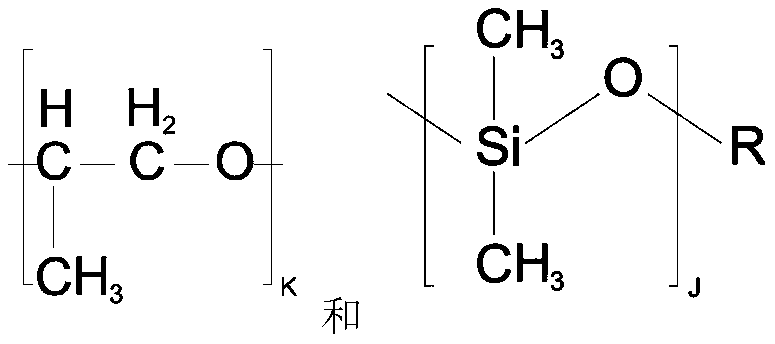

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the present invention, the preferred embodiments of the present invention will be described below in conjunction with examples, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention, rather than limiting the claims of the present invention.

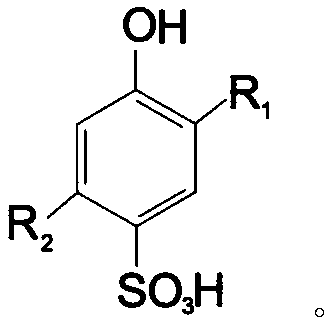

[0031] According to a preferred embodiment of the present invention, the additive used in the methanesulfonic acid method tin electroplating process will be described in detail below. In this embodiment, the additive used in the methanesulfonic acid method tin electroplating process is The modified product of phenolsulfonic acid, specifically the binary substituent on the benzene ring in phenolsulfonic acid, in which two substituents are respectively replaced by R 1 And R 2 .

[0032] In the first embodiment of the present invention, the additive of the tin electroplating process in the methanesulfonic acid method is a modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com