Device and method for improving seam smoothness of easy-care fabric

A flatness and fabric technology, applied to the seams of textile materials, sewing equipment, sewing machine components, etc., can solve the problems of poor sewing performance, poor flatness of garment seams, waste of manpower and material resources, etc., and achieve uniform results Accurate, improve flatness, reduce manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present invention will be further described below in conjunction with accompanying drawing.

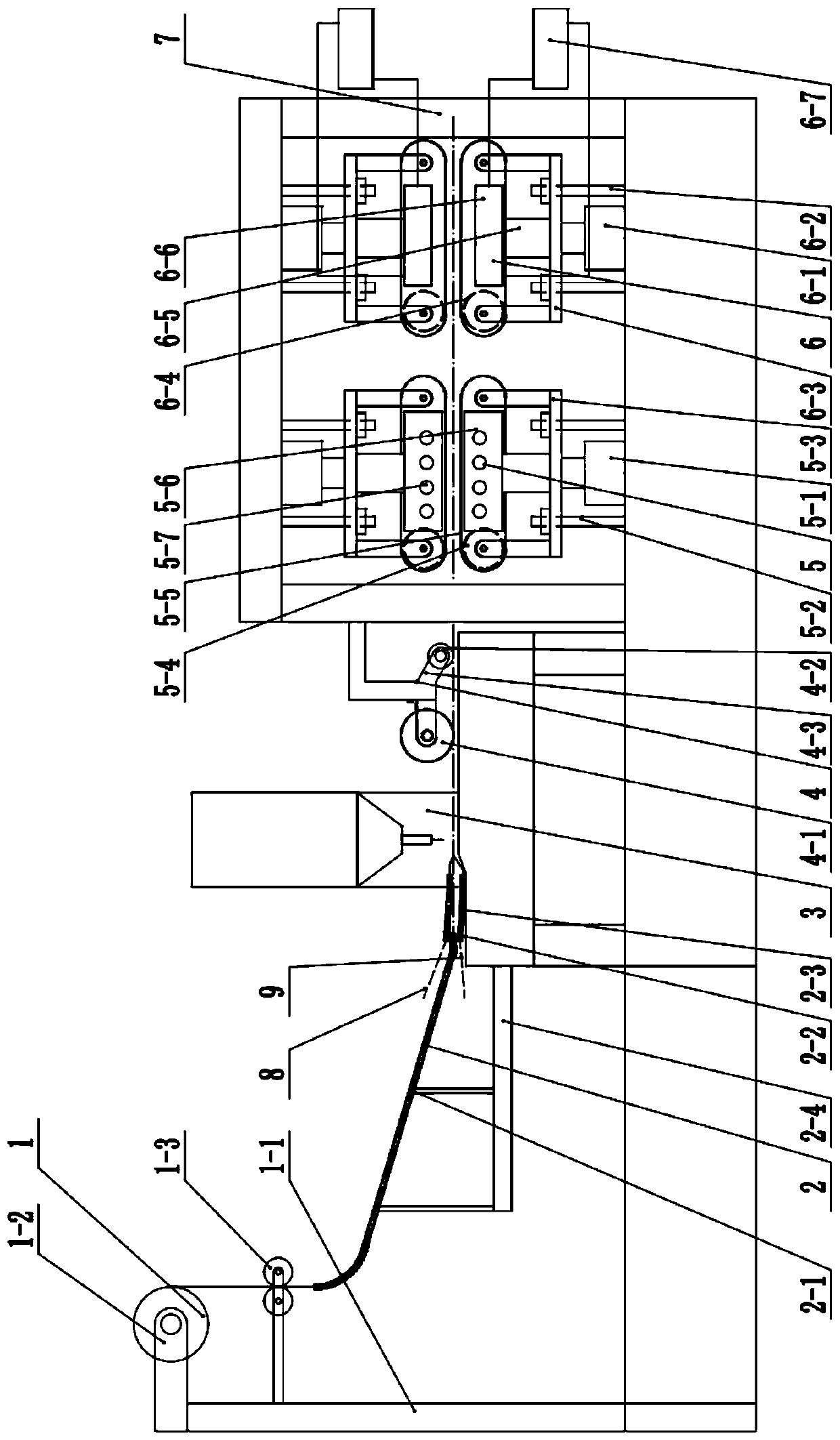

[0035] like Figure 1-2 As shown, a device for improving the seam flatness of non-ironing fabrics according to the present invention includes:

[0036] The upper molding mechanism 1 is used for unwinding and conveying the molding 10 used for non-ironing;

[0037] The guide 2 before sewing is arranged on the rear side of the upper molding mechanism 1, and is used to introduce the molding 10, the upper fabric 8 and the lower fabric 9 into the sewing area;

[0038] The sewing machine 3 is arranged on the rear side of the guide 2 before sewing, and is used to sew the molding 10, the upper fabric 8 and the lower fabric 9, and controls the forward speed of the sewn fabric through the needle speed;

[0039] The heating unit 5 is arranged on the rear side of the sewing machine 3, and is used for melting the molding 10 on the inside of the sewn fabric, and stretching and shaping t...

Embodiment 2

[0061] S3 conveys the preliminary fabric to the heating part 5 through the driving roller 4-2 of the pressing guide wheel 4 for pressurization and heating, and adjusts the transmission speed of the heating part 5. The transmission speed of the heating part 5 is the sewing speed of the sewing machine 3 1 times, the heating part 5 stretches and flattens the inner fillet 10 after melting;

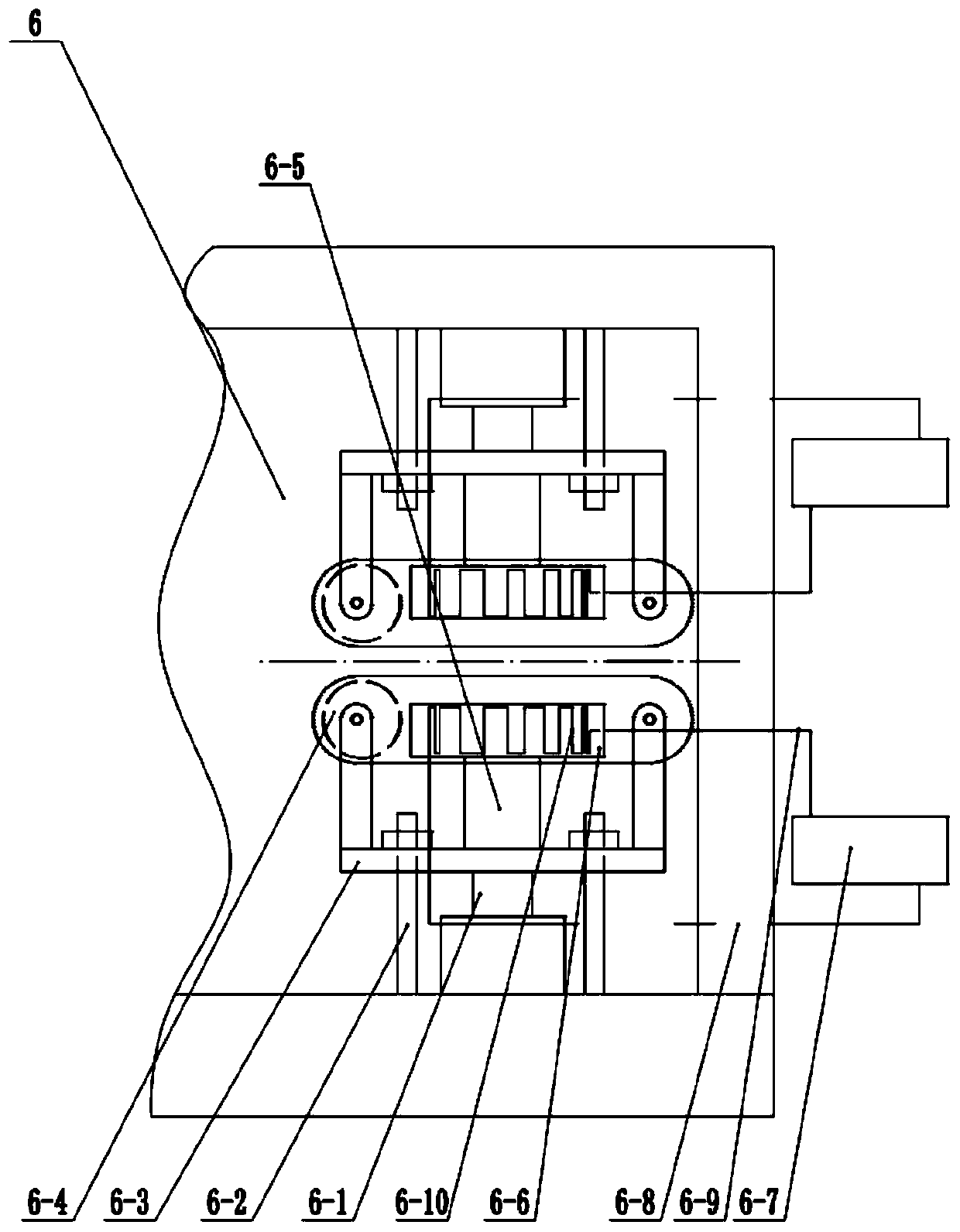

[0062] S4 cools and presses the stretched and flattened fabric through the cooling part 6, and compresses and transmits it. The cooling part 6 adjusts its transmission speed. The transmission speed of the cooling part 6 is 1 times the transmission speed of the heating part 5. The cooling part 6 is used to Stretch and flatten the inner molding 10 after cooling.

[0063] The speed of the sewing machine 3 is 100mm / s in the step S2;

[0064] The heating temperature of the heating part 5 described in step S3 is 140°C, and the pressure of the heating part 5 on the sewing fabric is controlled at 25N...

Embodiment 3

[0068] S3 conveys the preliminary fabric to the heating part 5 through the driving roller 4-2 of the pressing guide wheel 4 for pressurization and heating, and adjusts the transmission speed of the heating part 5. The transmission speed of the heating part 5 is the sewing speed of the sewing machine 3 1.05 times of , the heating part 5 stretches and flattens the inner fillet 10 after melting;

[0069] S4 cools and presses the stretched and flattened fabric through the cooling part 6, and compresses and transmits it. The cooling part 6 adjusts its transmission speed. The transmission speed of the cooling part 6 is 1.05 times that of the heating part 5. The cooling part 6 is used to Stretch and flatten the inner molding 10 after cooling.

[0070] The speed of sewing machine 3 is 150mm / s in the step S2;

[0071] The heating temperature of the heating part 5 described in step S3 is 170°C, and the pressure of the heating part 5 on the sewing fabric is controlled at 50N;

[0072] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com