An automatic finger beam device

An automatic, beam-fingering technology, applied in drill pipe, casing, drill pipe, etc., can solve the problems of high labor intensity and high operation risk, and achieve the effect of high work reliability, long service life and improved practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

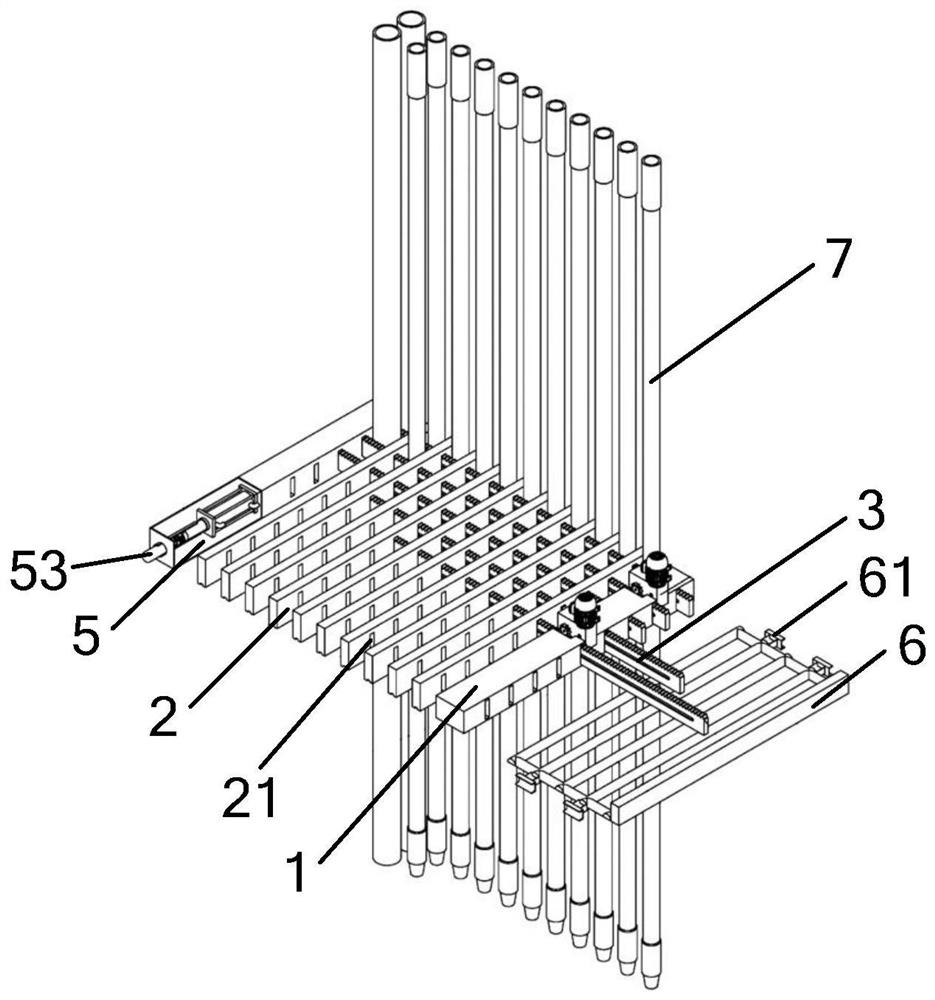

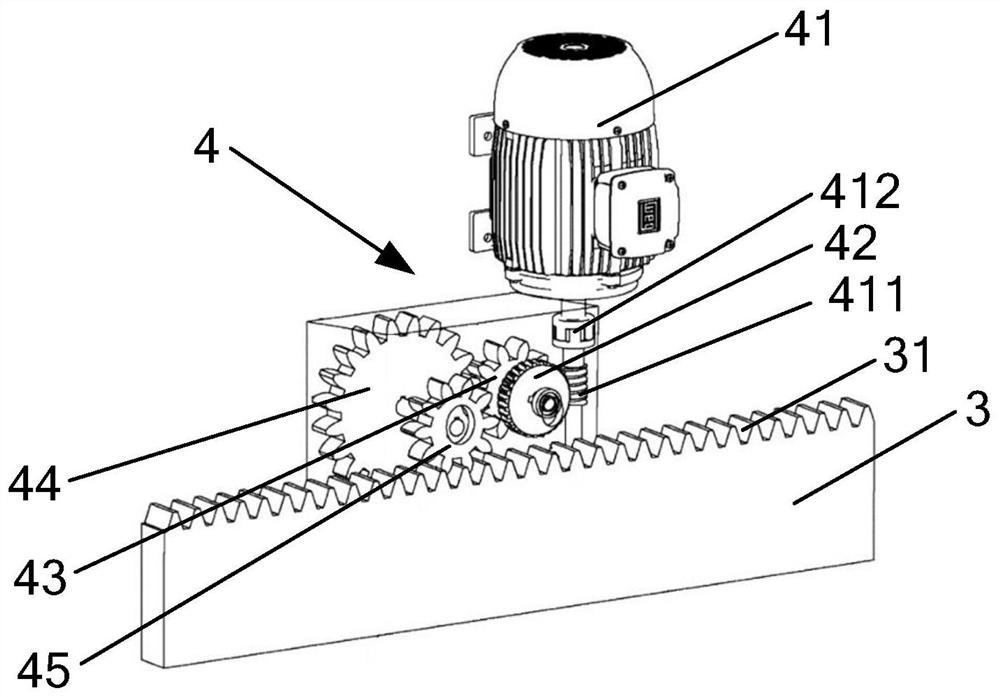

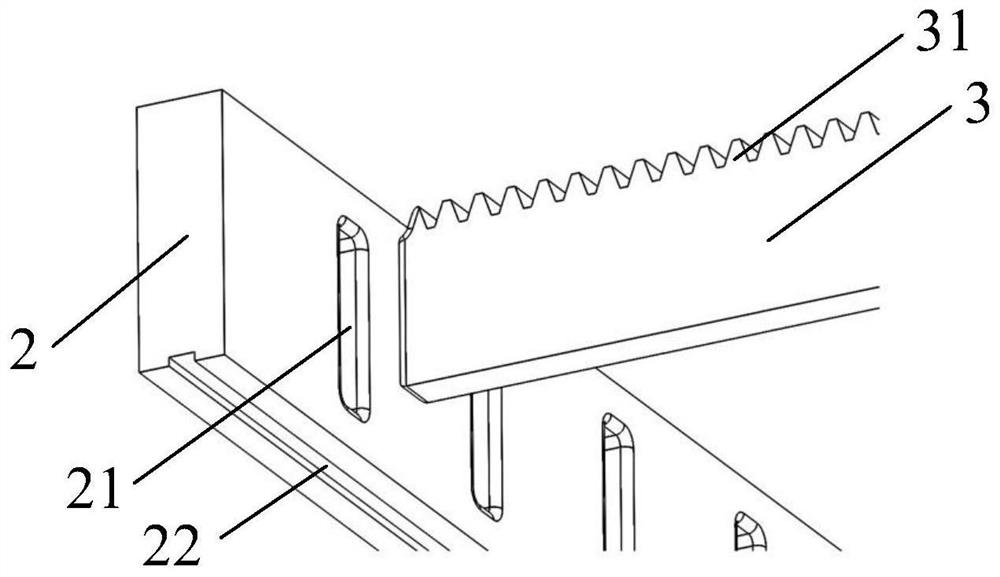

[0016] In order to make the purpose, technical solution and advantages of the application clearer, the embodiments of the application will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

[0017] The traditional finger beam device blocks a single working tube through a single opening and closing rod, and fixes the working tube in a limited position. However, due to the strong wind and waves on the offshore platform, the working tube may be affected by the wind and the opening and closing rod will be hit and opened (that is, the traditional The opening and closing rod cannot form a reliable protection for the working tube), causing misoperation and accidents. Moreover, since the traditional fingerboard device uses a single motor to control a single opening and closing lever, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com