Method for improving recovery ratio of high pour point oil reservoir

A technology of high pour point oil and recovery factor, applied in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve the problems of unmentioned, hidden danger of explosion, etc., to improve the flow performance, improve the validity period, and reduce the investment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Test reservoir D of an oil production plant in Shengli Oilfield 12 General situation: Reservoir temperature is 75°C, salinity of formation water is 25682mg / L, viscosity of crude oil is 160mPa.s, freezing point is 45°C, wax content is 35.2%, permeability is 1200×10 -3 μm 2 , the comprehensive water cut of the reservoir is 95.2%, and the geological reserves are 3.5×10 6 t. Utilize the method of the present invention to improve the recovery factor of this block, concrete steps are as follows:

[0040] (1) Screening of test reservoirs

[0041]Test reservoir D 12 The temperature is 75°C, the salinity of formation water is 25682mg / L, the viscosity of crude oil is 160mPa.s, the freezing point is 45°C, and the wax content is 35.2%. The screening criteria of the test reservoirs of the present invention are met, so the present invention can be practiced.

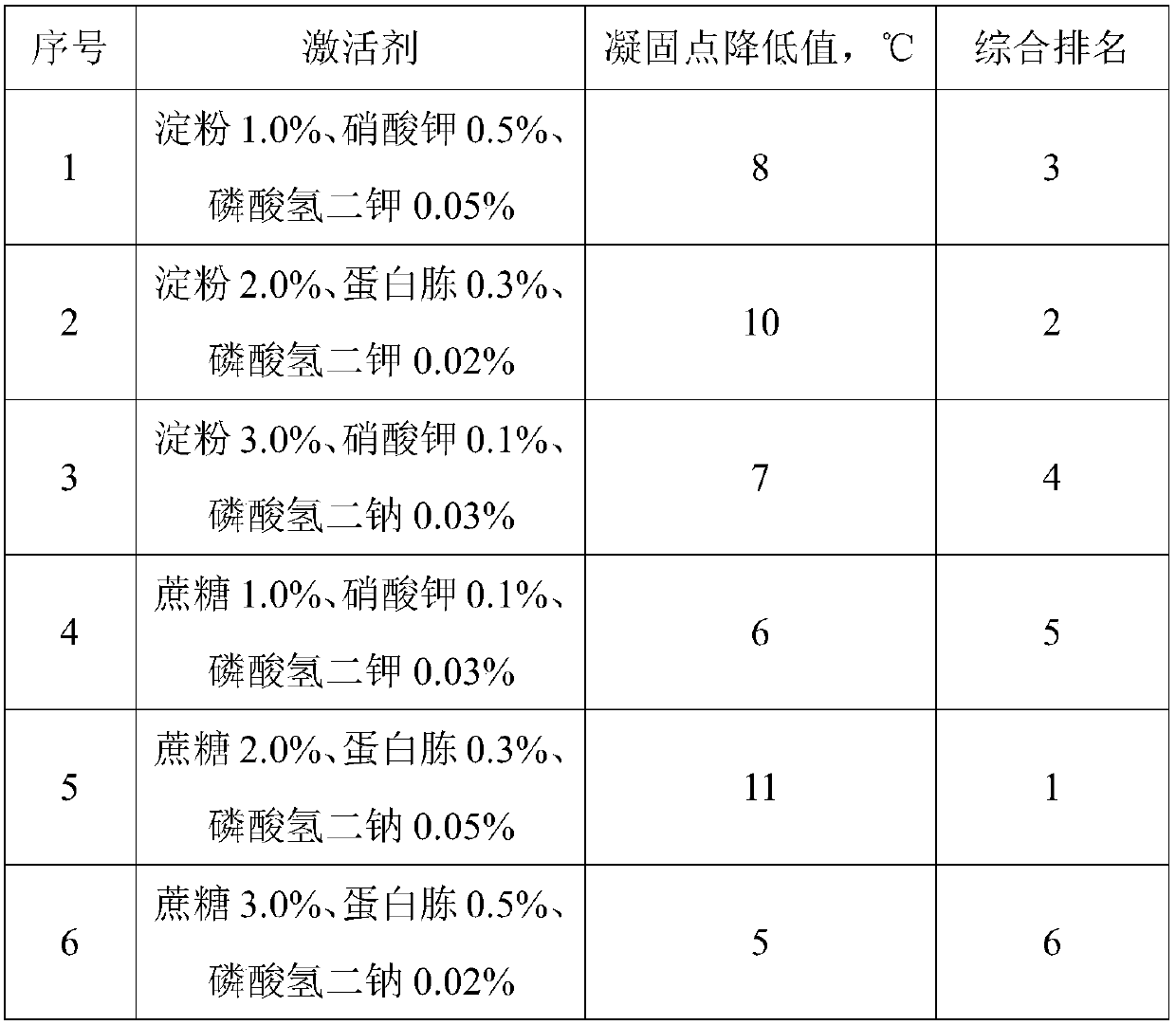

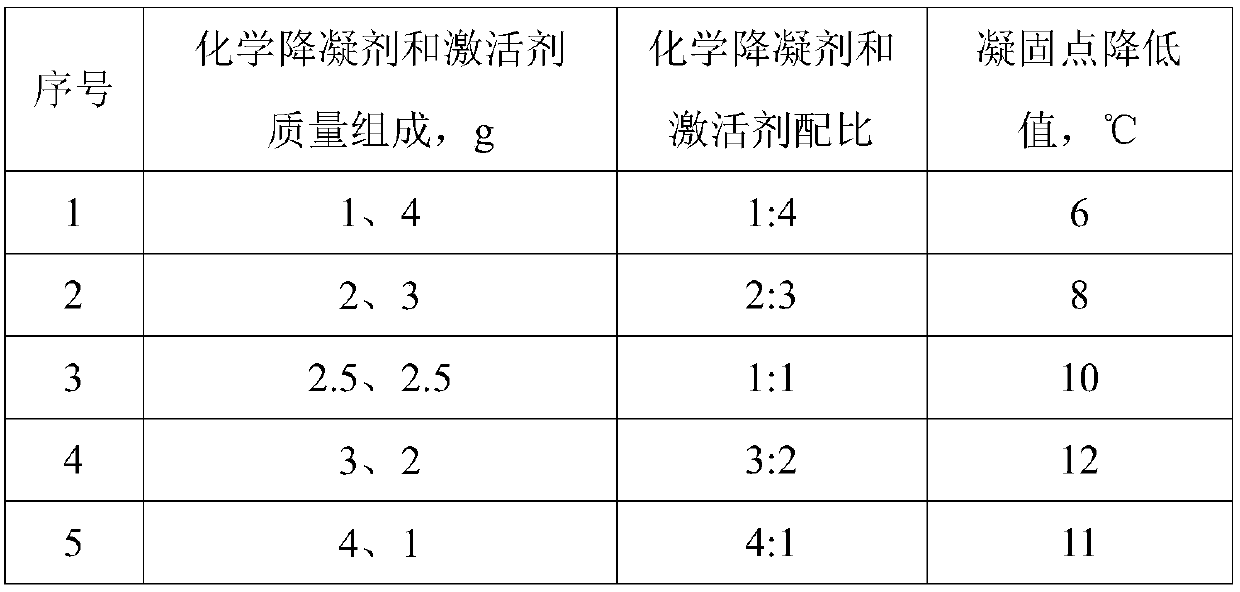

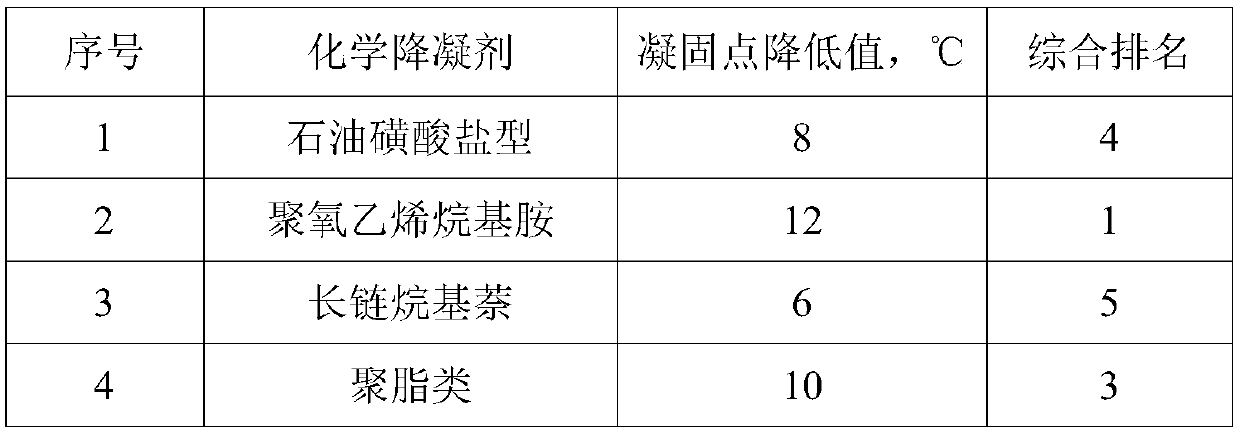

[0042] (2) Screening of chemical pour point depressants

[0043] The screening of chemical pour point depressants incl...

Embodiment 2

[0074] Test reservoir E of an oil production plant in Shengli Oilfield 21 General situation: Reservoir temperature is 70°C, salinity of formation water is 18623mg / L, viscosity of crude oil is 220mPa.s, freezing point is 48°C, wax content is 38.5%, permeability is 1500×10 -3 μm 2 , the comprehensive water cut of the reservoir is 97.3%, and the geological reserves are 3.2×10 6 t. Utilize the method of the present invention to improve the recovery factor of this block, concrete steps are as follows:

[0075] (1) Screening of test reservoirs

[0076] Test reservoir E 21 The temperature is 70°C, the salinity of formation water is 18623mg / L, the viscosity of crude oil is 220mPa.s, the freezing point is 48°C, and the wax content is 38.5%. The screening criteria of the test reservoirs of the present invention are met, so the present invention can be practiced.

[0077] (2) Screening of chemical pour point depressants

[0078] The screening of chemical pour point depressants inc...

Embodiment 3

[0110] Test reservoir D of an oil production plant in Shengli Oilfield 15 General situation: Reservoir temperature is 65°C, salinity of formation water is 32567mg / L, viscosity of crude oil is 483mPa.s, freezing point is 48°C, wax content is 38.8%, permeability is 1100×10 -3 μm 2 , the comprehensive water cut of the reservoir is 98.0%, and the geological reserves are 7.5×10 6 t. Utilize the method of the present invention to improve the recovery factor of this block, concrete steps are as follows:

[0111] (1) Screening of test reservoirs

[0112] Test reservoir D 15 The temperature is 65°C, the salinity of formation water is 32567mg / L, the viscosity of crude oil is 483mPa.s, the freezing point is 48°C, and the wax content is 38.8%. The screening criteria of the test reservoirs of the present invention are met, so the present invention can be practiced.

[0113] (2) Screening of chemical pour point depressants

[0114] The screening of chemical pour point depressants inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com