Float type composite power plunger device

A compound power and float type technology, which is applied to parts of pumping devices for elastic fluids, piston pumps, machines/engines, etc., can solve the problems of large energy consumption and a lot of energy consumption for driving plunger pumps, and achieve easy Promote and use, wide range of uses, reduce the effect of matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

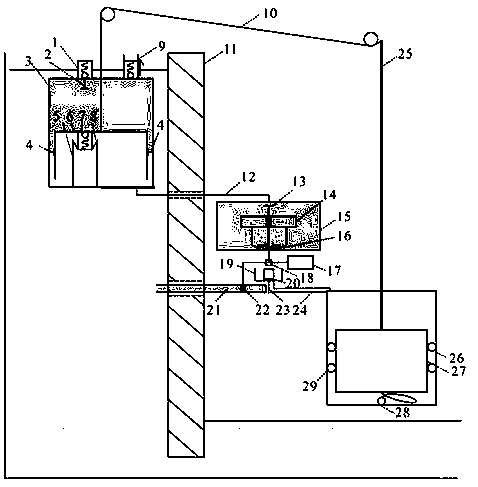

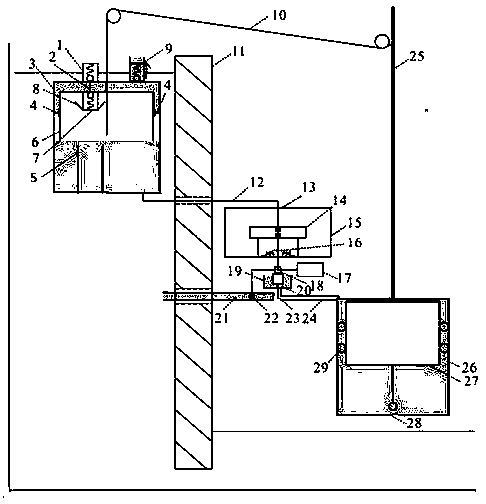

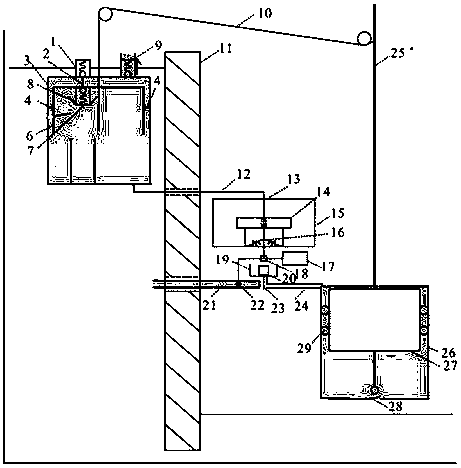

[0025] With reference to each figure, a float type composite power plunger device, said device includes a lifting mechanism capable of lifting infusion, a lifting mechanism for lifting, and a gas-liquid displacement work mechanism that provides power for the lifting mechanism and the lifting mechanism; The lifting part of the lifting mechanism is connected with the lifting part of the lifting mechanism through a power transmission chain; The buoyancy powers the lifting mechanism and the lifting mechanism; the lifting mechanism is placed in the high water zone and the lifting mechanism is located above the low water zone.

[0026] The lifting mechanism includes a pump body 3 and a plunger 6, the plunger 6 is located in the pump body 3, and the ring cavity between the plunger 6 and the pump body 3 is provided with a sealing baffle 4 for sealing fit, and the sealing baffle 4 is fixed On the inner wall of the pump body 1; the top of the plunger 6 is provided with a plunger exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com