Connecting structure of mutual inductor and wiring terminal button, manufacturing method and instrument

A technology of connection structure and manufacturing method, which is applied in the field of connection structure between transformers and terminal buttons, can solve the problems that the welding hot-melt process is difficult to achieve consistency, affects the normal use of devices, and is not stable enough, so as to improve the connection Consistency, reduce contact resistance, reduce the effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

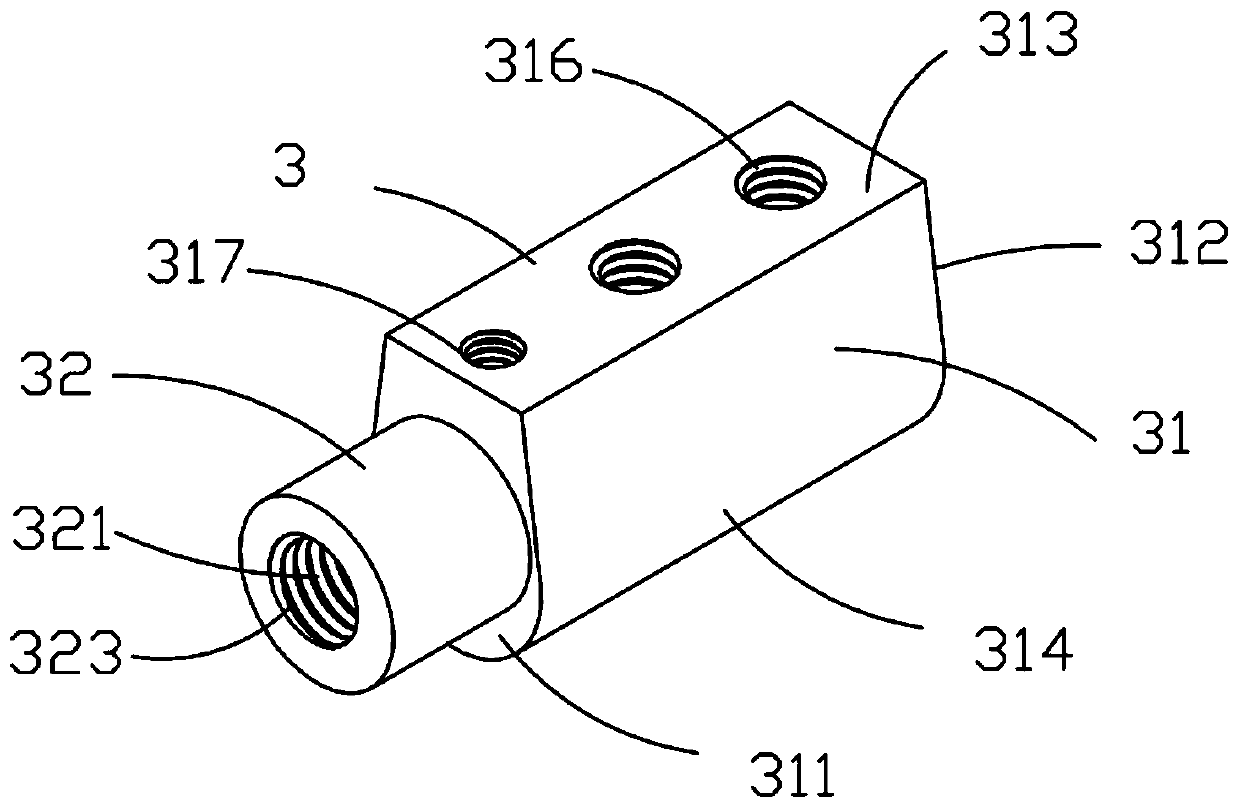

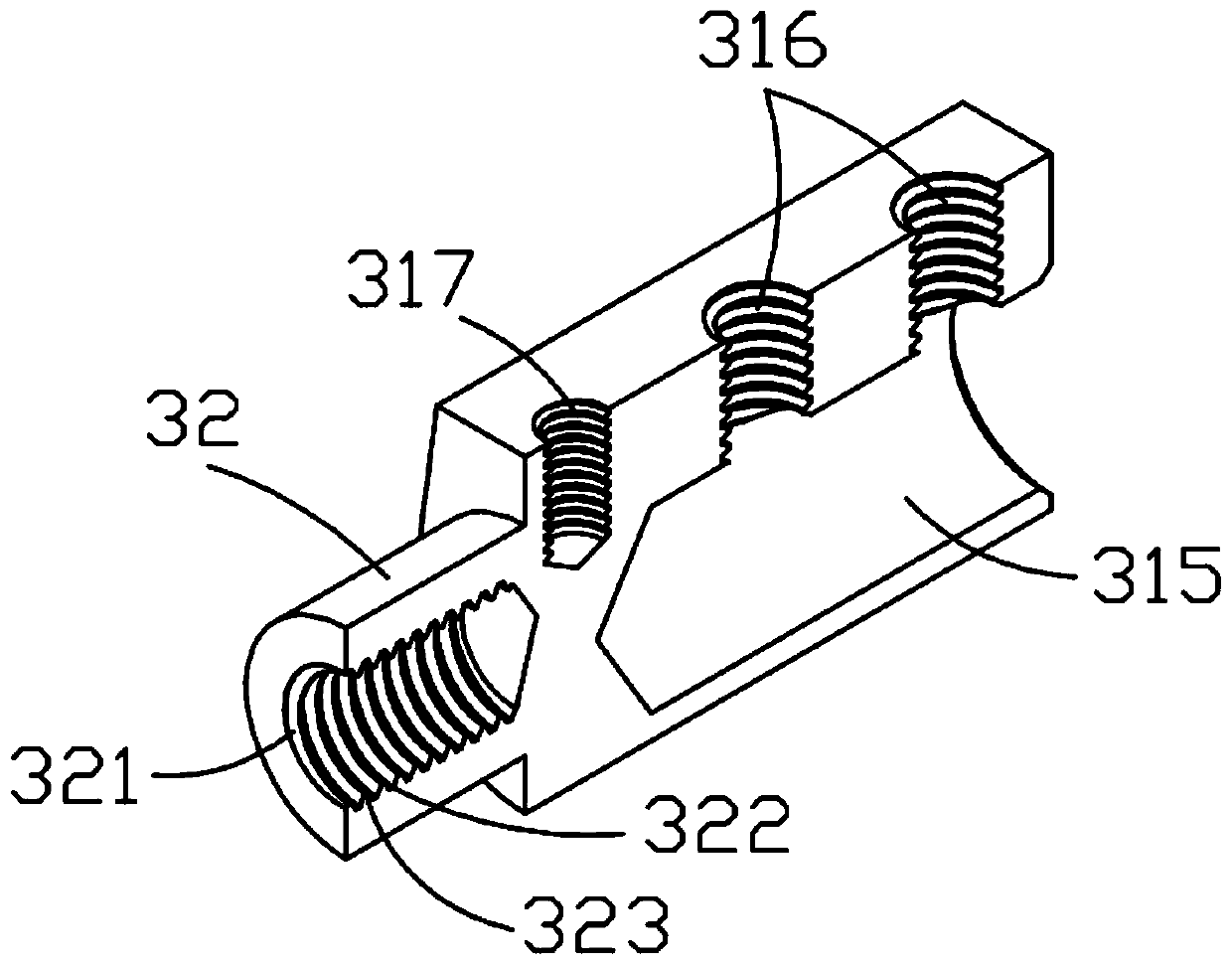

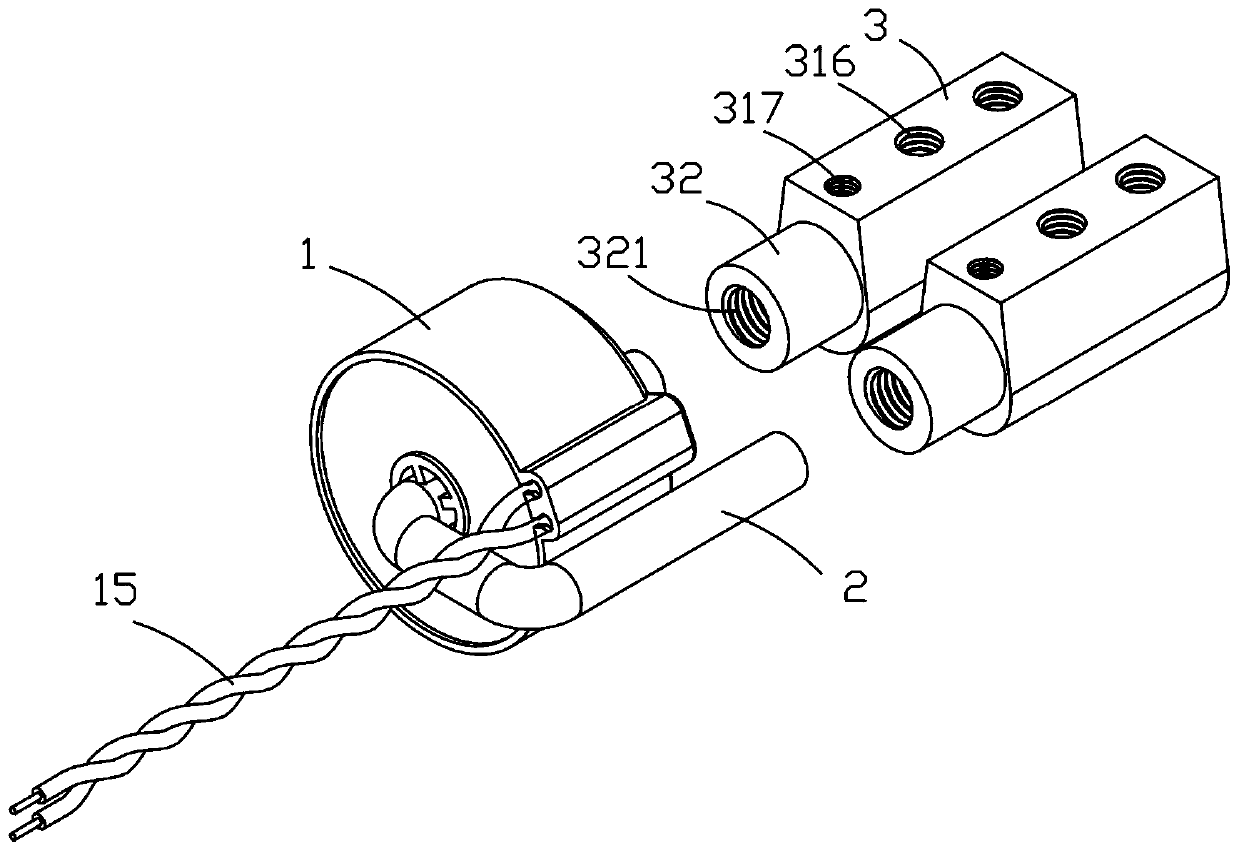

[0068] Embodiment 1: When the diameter of the primary current wire 2 is φ3.5mm, the thread diameter of the connection hole 321 is M4.0mm, the depth of the connection hole 321 is 10.0mm, and the outer diameter of the columnar body 32 is φ7.0-8.5mm, both Connected contact resistance 0-5uΩ.

Embodiment 2

[0069] Embodiment 2: When the diameter of the primary current wire 2 is φ5.0mm, the thread diameter of the connection hole 321 is M6.0mm, the depth of the connection hole 321 is 9.0mm, and the outer diameter of the columnar body 32 is φ8.5-10.0mm, both Connected contact resistance 0-5uΩ.

Embodiment 3

[0070] Embodiment 3: When the diameter of the primary current wire 2 is φ6.0mm, the thread diameter of the connection hole 321 is M7.0mm, the depth of the connection hole 321 is 8.0mm, and the outer diameter of the columnar body 32 is φ10.5-12.5mm, both Connected contact resistance 0-5uΩ.

[0071] Since this product is a power device that requires large-scale production and application, it has very high requirements for the stability of its own power transmission and adaptability to the environment:

[0072] On the one hand, in the process of use, if there is a large current input, or a long-term current input, it is easy to cause high temperature in the connection structure between the transformer and the terminal button, and the connection structure between the transformer and the terminal button at high temperature The safety and stability of the environment are related to the measurement accuracy of the electric energy meter, and in serious cases, it is related to the safe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com