Intelligent medicinal acupoint patch hobbing forming machine

A technology of acupoint sticking and molding machines, which is applied in the direction of making medicines into special physical or ingestible devices, metal processing, dressings, etc. It can solve the problems of easily damaged knives, poor position consistency, and different frequency of magnet landing , to achieve the effect of high efficiency, good location consistency and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

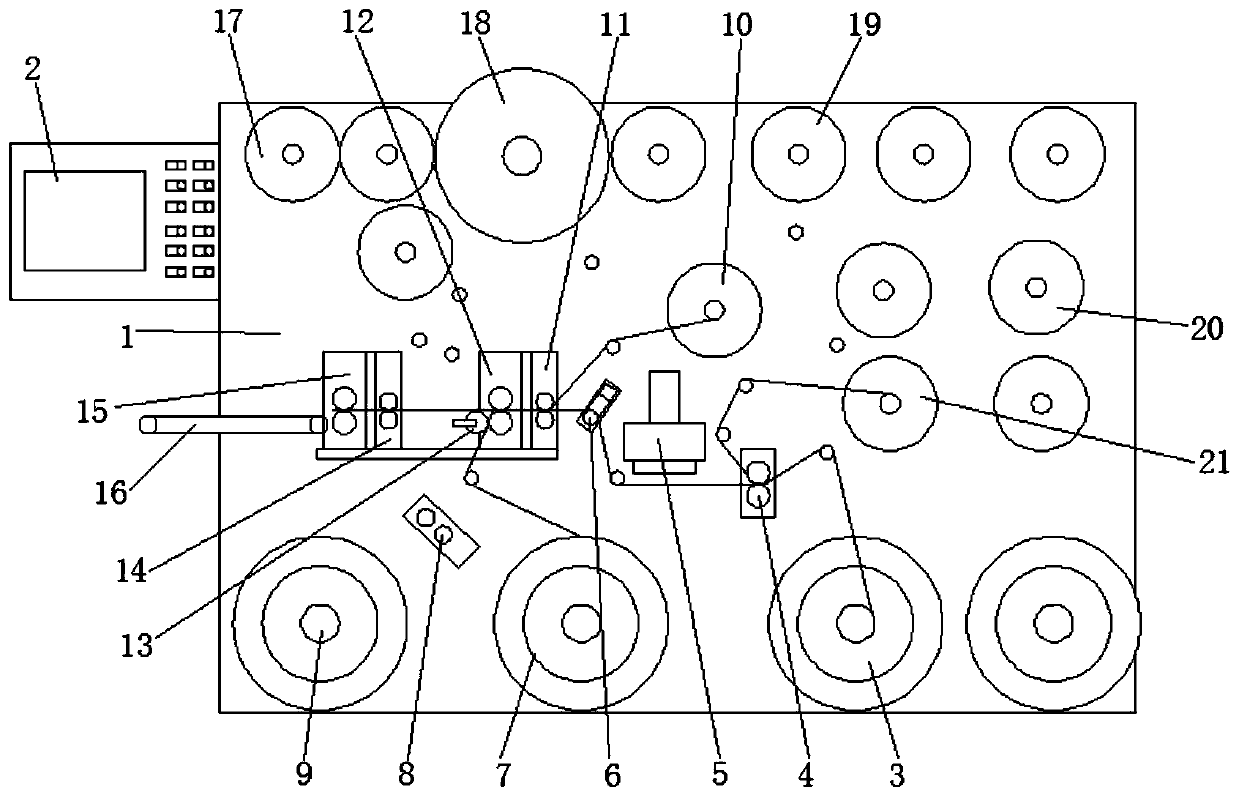

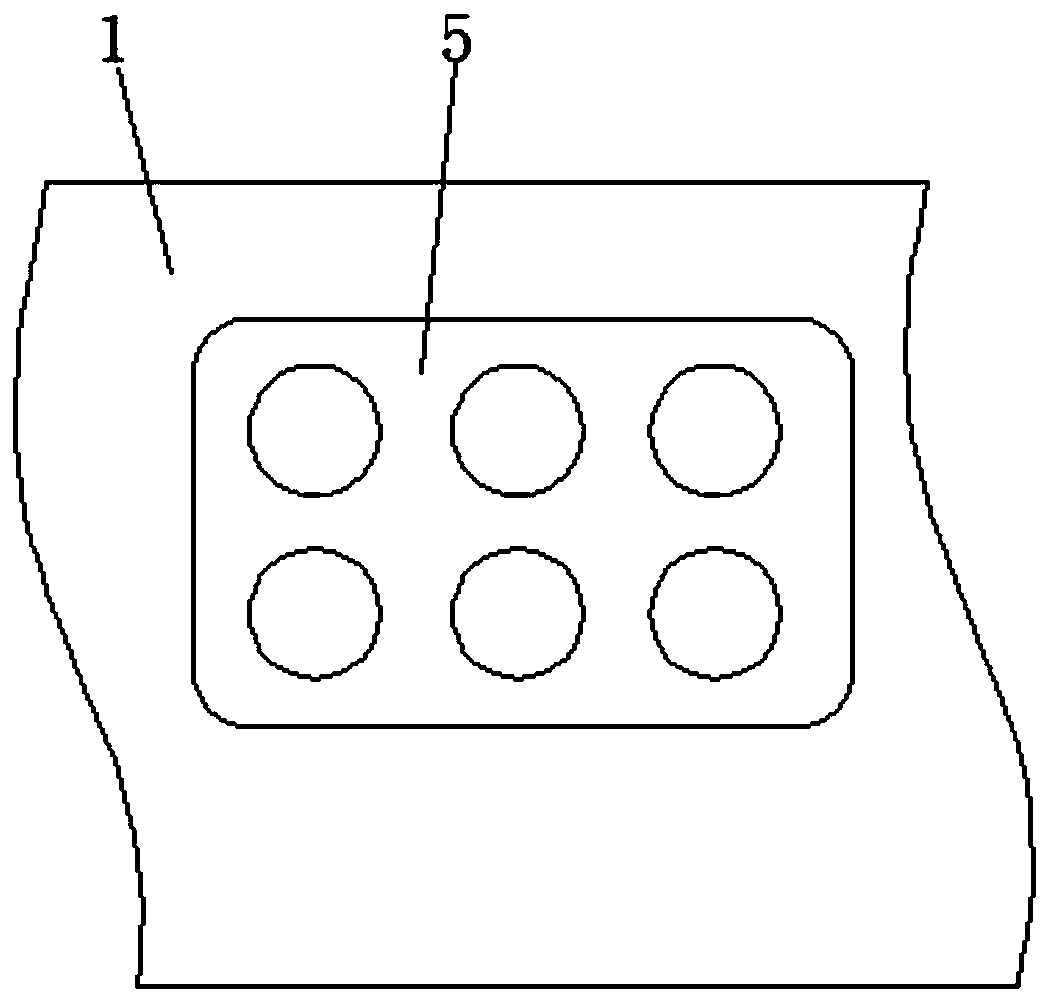

[0019] Reference Figure 1-2 , An intelligent medicine stick acupoint paste roll-cutting forming machine, comprising a frame 1, a controller 2 is fixedly connected to one side of the frame 1, and two core releasing wheels 3 are fixedly connected to the upper surface of the frame 1, The role of the core release wheel 3 is to release the black plaster. One side of the core release wheel 3 is fixedly connected with a paper adhesive peeling mechanism 4, which is used to peel off the paper adhesive on the surface of the black plaster, and the paper adhesive peeling mechanism 4 is fixed. On the frame 1, one side of the paper glue peeling mechanism 4 is fixedly connected with a direction adjusting mechanism 6. The function of the direction adjusting mechanism 6 is to change the moving direction of the black plaster. The frame 1 is fixedly connected with a steel ball magnet blanking mechanism 5. The steel ball magnet blanking mechanism 5 can install six steel balls in a single channel,...

Embodiment 2

[0023] Reference Figure 1-2 As another preferred embodiment of the present invention, the difference from embodiment 1 is that the rolling mechanism includes a first bonding mechanism 11, which is used to bond the base tape and the black plaster, and the first bonding mechanism The mechanism 11 is fixed on the frame 1, and the frame 1 is fixedly connected with a core roller mechanism 12. The function of the core roller mechanism 12 is to squeeze the first adhesive patch to make the black plaster adhere to the base tape tightly. The core roller mechanism 12 is located on one side of the first bonding mechanism 11, and the center of the first bonding mechanism 11 and the roller core mechanism 12 are on the same straight line.

Embodiment 3

[0025] Reference Figure 1-2 As another preferred embodiment of the present invention, the difference from Embodiment 1 is that the roll cutting mechanism includes a second bonding mechanism 14. The second bonding mechanism 14 is fixed on the frame 1, and a part of the second bonding mechanism 14 A rolling cutter 15 is fixedly connected to the side. The function of the rolling cutter 15 is to cut the formed medicine stick. The rolling cutter 15 is fixed on the frame 1, and the outlet of the second bonding mechanism 14 is connected to the rolling cutter 15 The entrance is at the same height.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com