A kind of airflow dispensing equipment and dispensing method for electronic processing

An air flow and dispensing technology, which is applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, and can solve the problems of accelerating the efficiency and quality of workpiece dispensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

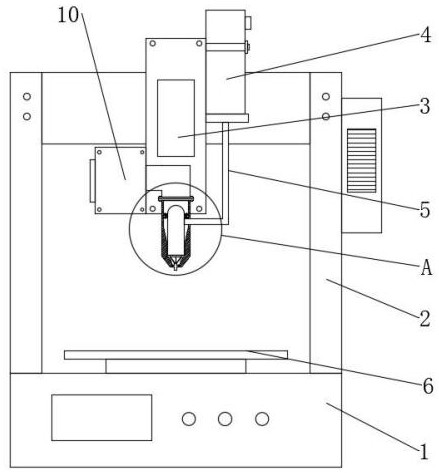

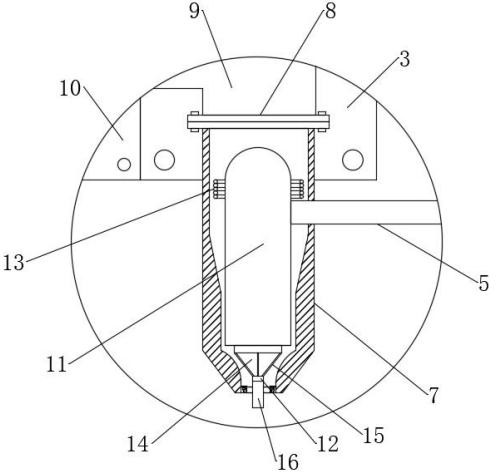

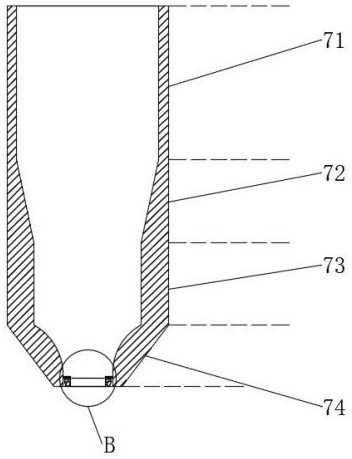

[0048] see Figure 1-2 , an air-flow dispensing device for electronic processing, including a dispensing workbench 1, a mobile support 2 is installed on the upper end of the dispensing workbench 1, most of the mobile support 2 can be designed as a three-axis motion mechanism at present, and the specific structure and function are in This will not go into details here, the mobile bracket 2 is equipped with a mounting plate 3, the upper end of the dispensing workbench 1 is fixedly connected with a receiving plate 6, the front end of the mounting plate 3 is fixedly connected with an inner changing air duct 7, and the inner side of the inner changing air duct 7 is provided. Dispensing head 11, the dispensing head 11 is an existing technology, the dispensing process can be automatically realized by setting parameters, the dispensing head 11 is connected with the glue replenishing hard tube 5, and the glue replenishing hard tube 5 runs through the inside and changes out of the air cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com