Folding equipment for textile fabric

A folding equipment and textile fabric technology, which is applied in the direction of folding thin materials, thin material processing, transportation and packaging, etc., can solve the problems of unrealized automatic non-marking textile fabric folding and reduce work efficiency, so as to achieve simple structure and improve production efficiency , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

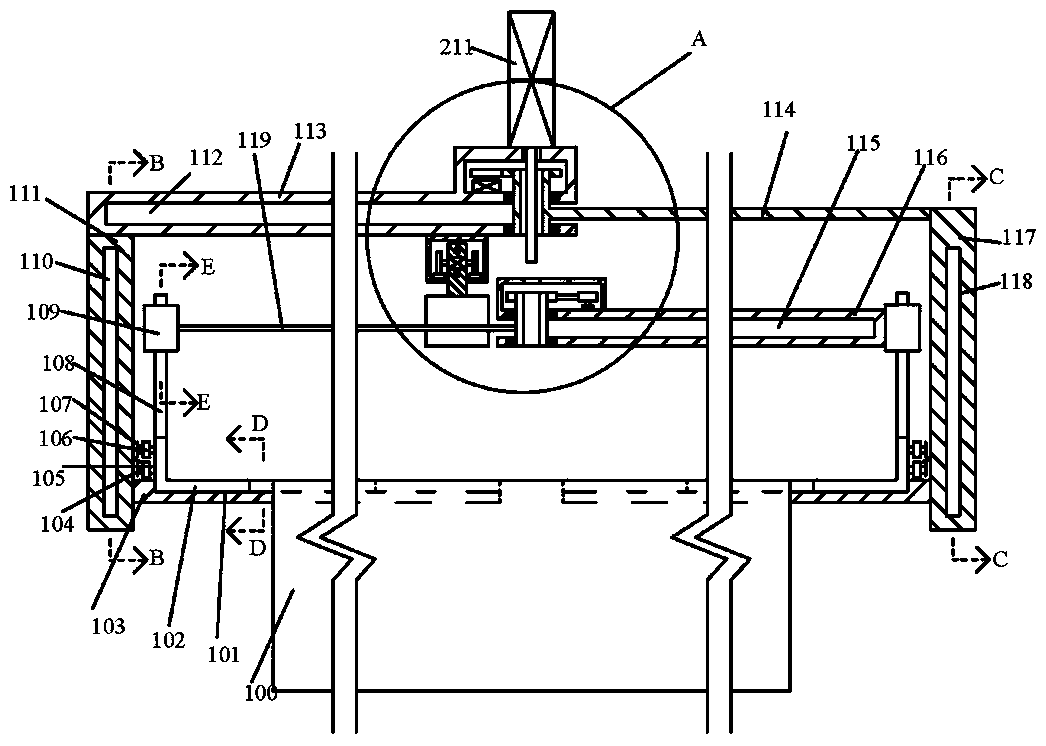

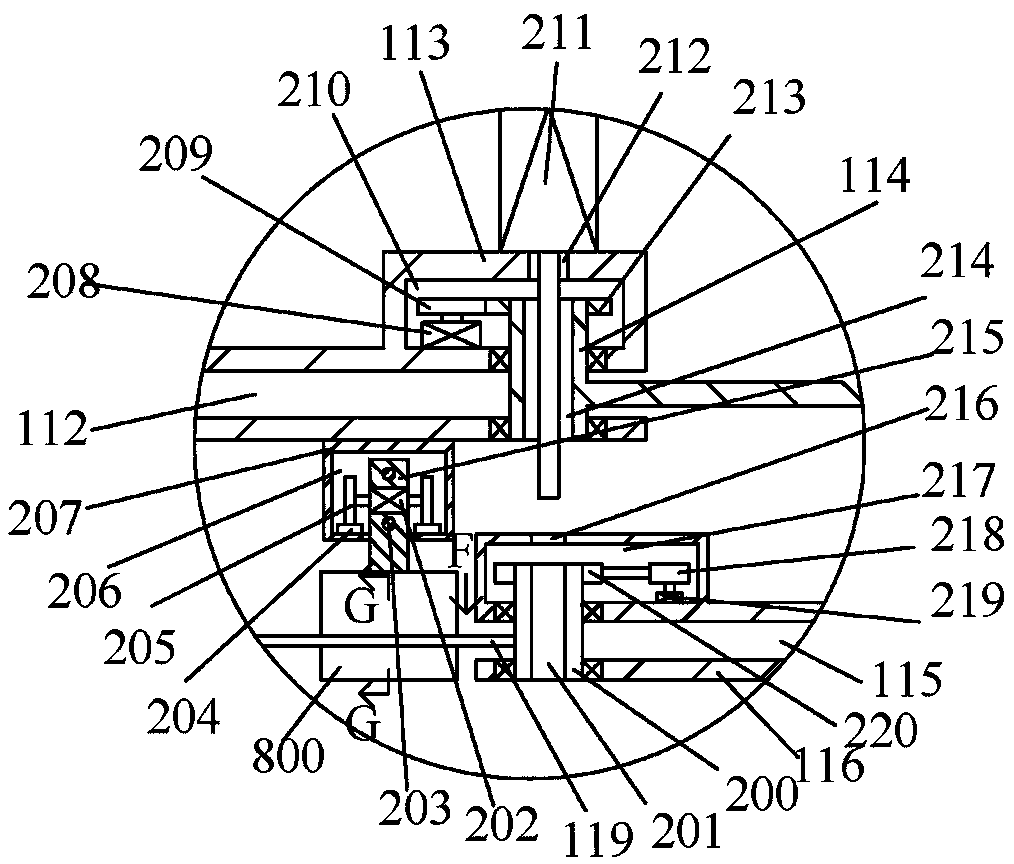

[0024] Combine below Figure 1-9 The present invention will be described in detail.

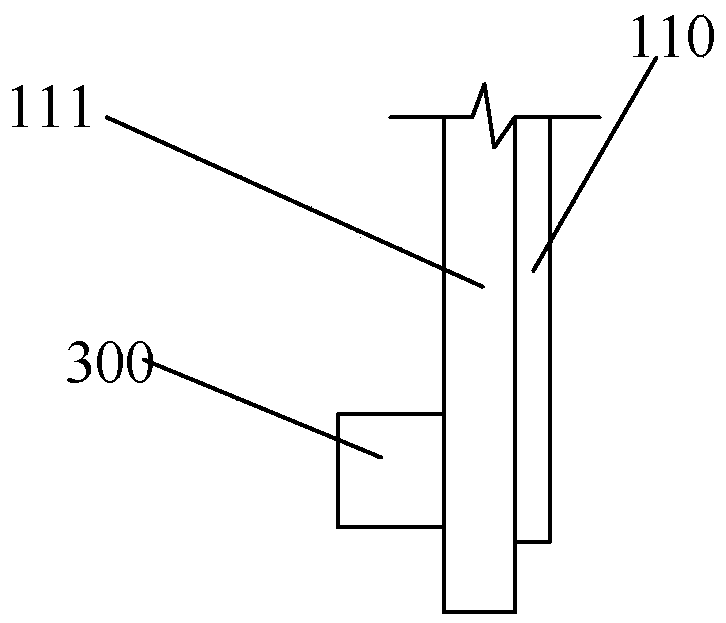

[0025] refer to Figure 1-9According to an embodiment of the present invention, a textile fabric folding device includes a swing plate 113 fixed to an external space support, a translation device, an overturning device, a lifting device and a telescopic device. Through the cavity 112, the gear cavity 210 located in the swing plate 113 is arranged above the penetration cavity 112. The lower end wall of the through cavity 201 is fixed with a rotating motor 208, and the upper end surface of the output shaft of the rotating motor 208 is fixed with a driving gear 209. The gear cavity The upper end wall of 210 is communicated with an opening cavity 212 with an opening facing upwards, and an engaging gear 213 is arranged on the right side of the driving gear 209. The transmission ratio between the driving gear 209 and the engaging gear 213 is 0.5, and the engaging gear 213 is fixed with a rotating ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap