Electrochemical Preparation of Aligned Carbon Nanotubes Embedded with Copper Nanoparticles

A technology of copper nanoparticles and carbon nanotubes, applied in jewelry and other directions, can solve the problems of cumbersome process, time-consuming, reducing copper azide sensitivity, etc., and achieve the effect of improving deposition density and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] References for the preparation of aligned carbon nanotubes [Guo Rui, Preparation method and application of carbon nanotube-filled oxidant composite energetic materials [D]; Nanjing University of Science and Technology, 2016]. Specifically:

[0023] 1) Weigh 37.82g of oxalic acid dihydrate and dissolve it in 1L of water to prepare a 0.3mol / L oxalic acid solution, weigh 6g of phosphoric acid and 1.8g of chromium trioxide and dissolve it in 92.2ml of water to prepare 6wt% phosphoric acid and 1.8wt% Tris For the mixed solution of chromium oxide, take 5g of phosphoric acid and dissolve it in 95ml of water to prepare 5wt% pore-enlarging solution. Use a 15*15mm aluminum-plated silicon chip as the anode, use a platinum sheet as the cathode, and use a DC power supply of 45V to oxidize for 16 minutes at a constant voltage; After one-step anodizing, put it into a mixed solution of phosphoric acid and chromium trioxide and place it in a constant temperature water bath at 70°C for 3...

Embodiment 1

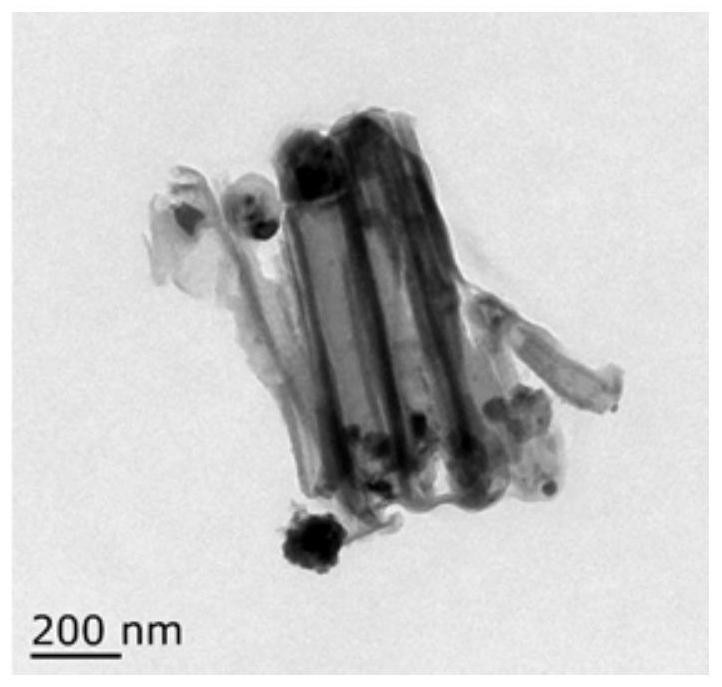

[0026] Dissolve 2.5g of copper sulfate pentahydrate and 2.5g of boric acid in water to prepare 100mL of electrolytic solution, and add 1mg of thiourea and 10mg of polyvinylpyrrolidone, that is, the additives used are 10mg / L of thiourea and 0.1g / L of polyethylene pyrrolidone. The porous alumina deposited with carbon nanotubes on the inner wall of the channel was used as the cathode, and the platinum wire electrode was used as the anode. The current density was controlled at 0.1mA, the constant current electrodeposition was 3h, and the temperature was 30°C. After the deposition, the sample was taken out, soaked in deionized water, and then put into a 6mol / L sodium hydroxide solution to remove the porous alumina template to obtain aligned carbon nanotubes embedded with copper nanoparticles, as shown in the transmission electron microscope image 3 .

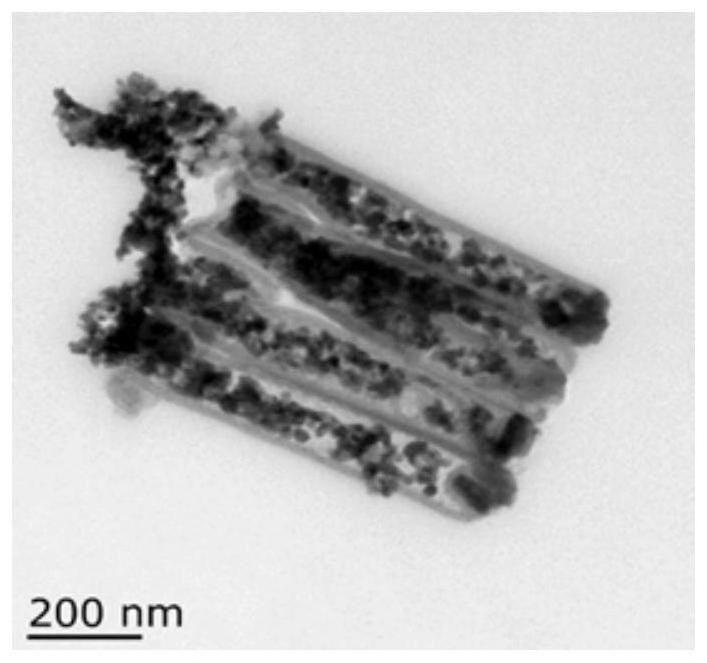

[0027] From image 3 , Figure 4 and Figure 5 It can be seen that when thiourea and polyvinylpyrrolidone are used as additive...

Embodiment 2

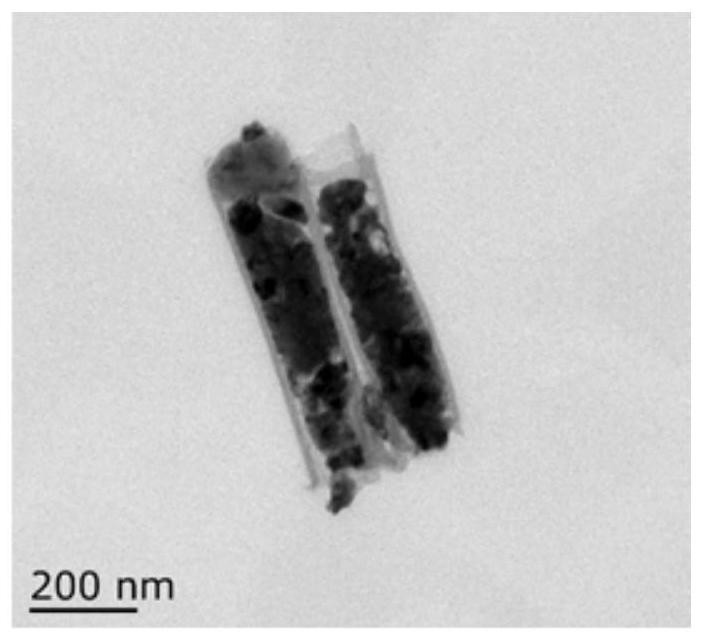

[0031] This example is basically the same as Example 1, except that the additives used are 15mg / L thiourea and 0.1g / L polyvinylpyrrolidone to obtain aligned carbon nanotubes embedded with copper nanoparticles, as shown in the transmission electron microscope Figure 4 .

[0032] From Figure 4 It can be seen that when the concentration of the thiourea additive is 15 mg / L, the prepared copper nanoparticles are deposited in the carbon nanotubes, the density of the copper nanoparticles does not decrease, and the copper particles do not agglomerate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com