Preparation method of staining-resistant wear-resistant finishing varnish

A varnish and a technology of preparation steps, which are applied in the field of preparation of stain-resistant and wear-resistant varnishes, can solve the problems of poor stain resistance, poor scratch resistance and wear resistance, and insufficient hardness, and achieve good chemical stability. properties, low surface energy, and enhanced binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

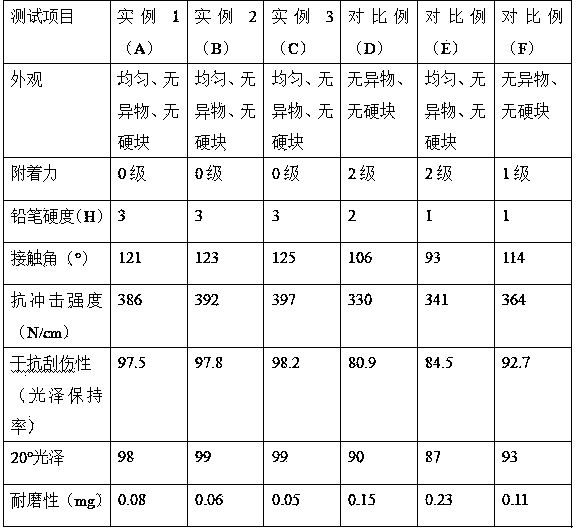

Examples

preparation example Construction

[0034] Preparation of natural silicone oil: Put 200g of oatmeal and 400mL of sodium silicate solution with a mass fraction of 35% into a water bath reaction kettle with a stirrer, heat the water bath to 70°C, start the stirrer, stir for 3 hours and use a mass fraction of Adjust the pH to neutral with 95% glacial acetic acid, then transfer it to a high-speed centrifuge, centrifuge at a high speed of 3500r / min for 12 minutes, remove the supernatant, separate and obtain the lower precipitate, wash the precipitate twice with water, and then transfer it to a set temperature of 70 In an oven at ℃, place a beaker under the precipitation, heat it for 10 hours, collect the natural silicone oil, and set it aside.

[0035] Preparation of graft enhancer: Add 6g of α-amylase and 100mL of starch gelatin with a mass fraction of 45% to the beaker, stir and disperse, then add 5g of 2,3-epoxypropyltrimethylammonium chloride, place the beaker In a water bath, heat up to 55° C., keep warm for 3 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com