Variable-working-condition gas boosting system and boosting method thereof

A technology of gas pressurization and variable working conditions, which is applied in the direction of fluid pressure actuation system components, fluid pressure converters, fluid pressure actuation devices, etc. System efficiency and chemical process and other issues to achieve the effect of strengthening heat transfer capacity, avoiding damage, and reducing swirl phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further described below in conjunction with accompanying drawing:

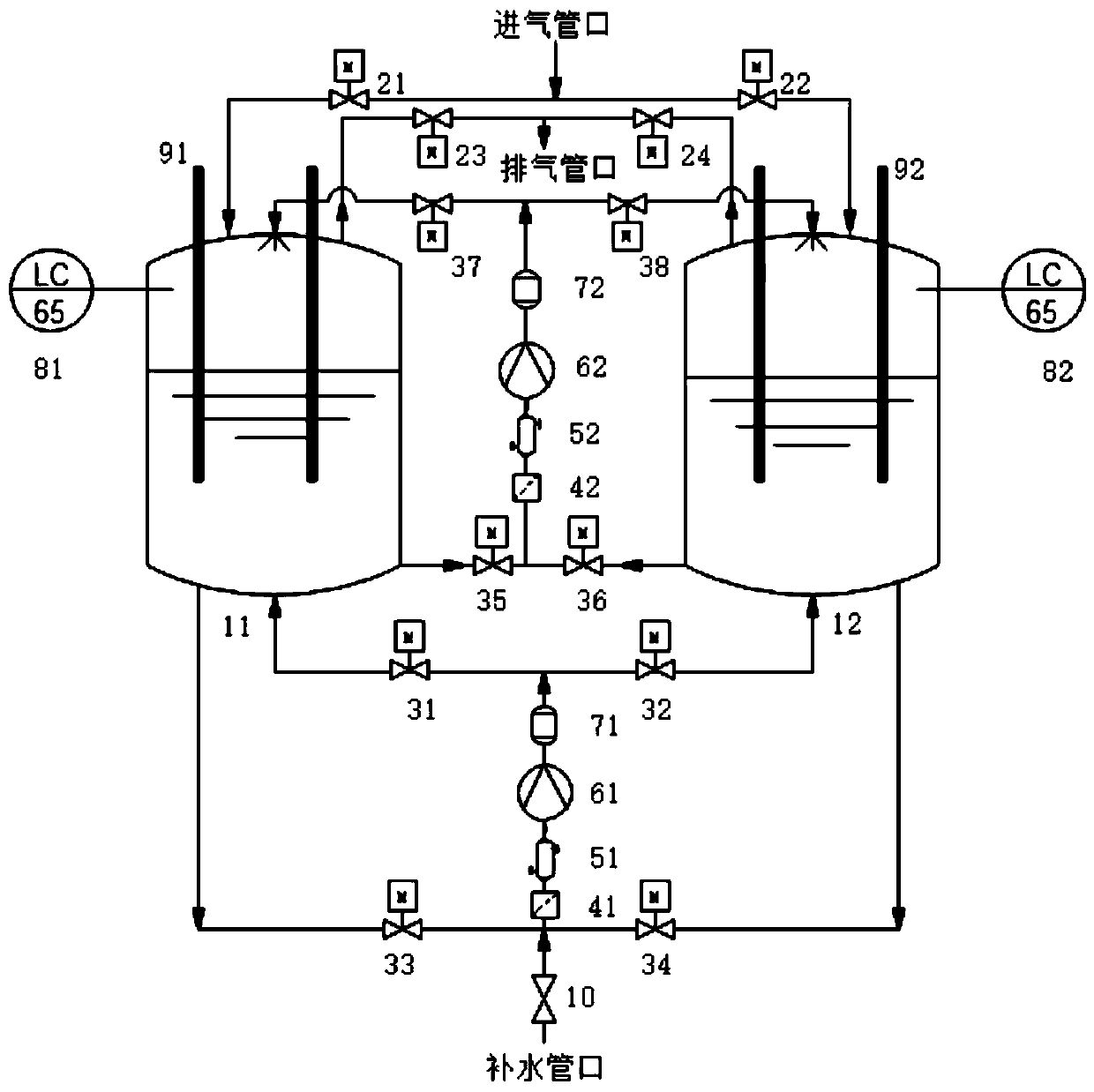

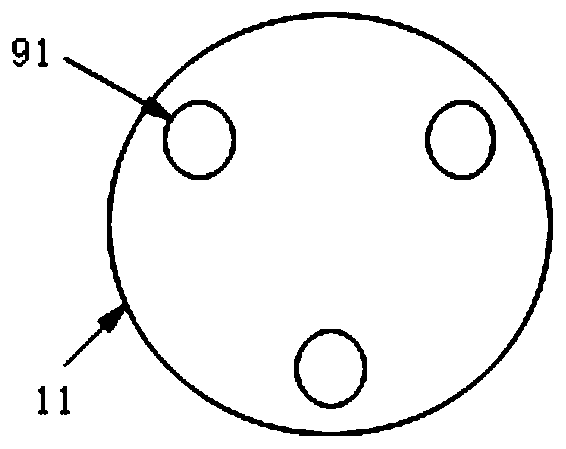

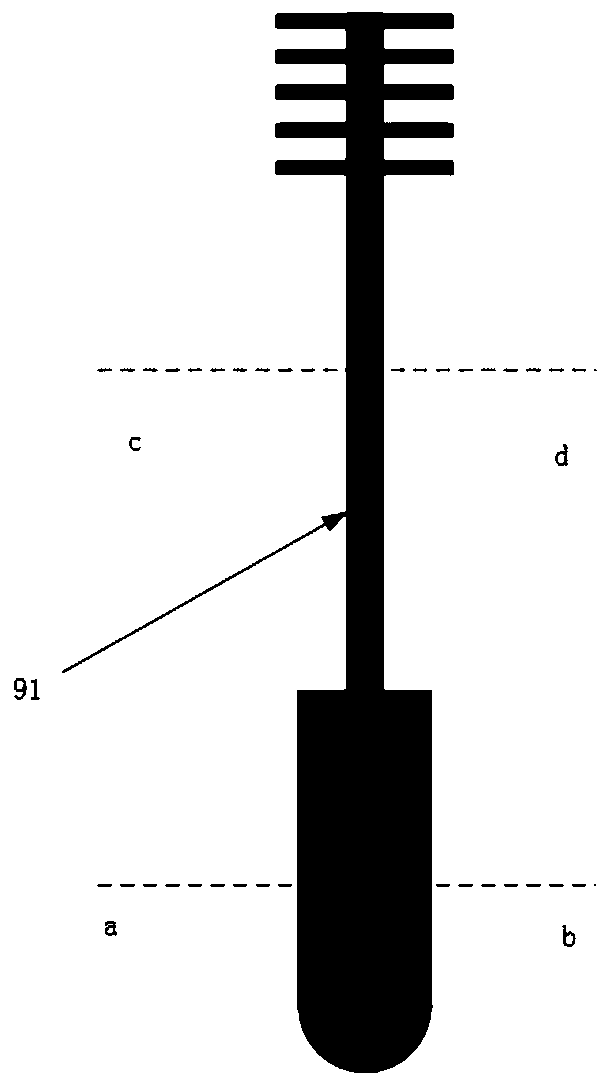

[0036] see Figure 1 to Figure 6 , a variable working condition gas pressurization system and pressurization method thereof, including intake and exhaust pipelines for controlling intake and exhaust, two high-pressure water and gas tanks for gas pressurization, and two high-pressure water and gas tanks for connecting The water pump unit pipeline and the spray circuit for spray cooling.

[0037] Such as figure 1As shown, the intake and exhaust pipelines include an intake pipeline and an exhaust pipeline connecting two high-pressure water and gas tanks in parallel; the corresponding intake pipelines of the first high-pressure water and gas tank 11 and the second high-pressure water and gas tank 12 There are a first air intake valve 21 and a second air intake valve 22; there are first exhaust valves 23 and second exhaust valves on the exhaust pipelines corresponding to the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com