Waste gas and liquid incineration disposal device applied to organosilicone industry

A treatment device and organosilicon technology, applied in steam generation methods using heat carriers, incinerators, combustion methods, etc., can solve problems such as easy blockage of boilers, short operating cycles, excessive dioxin emissions, etc., to avoid secondary Pollution, improve the effect of operating economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

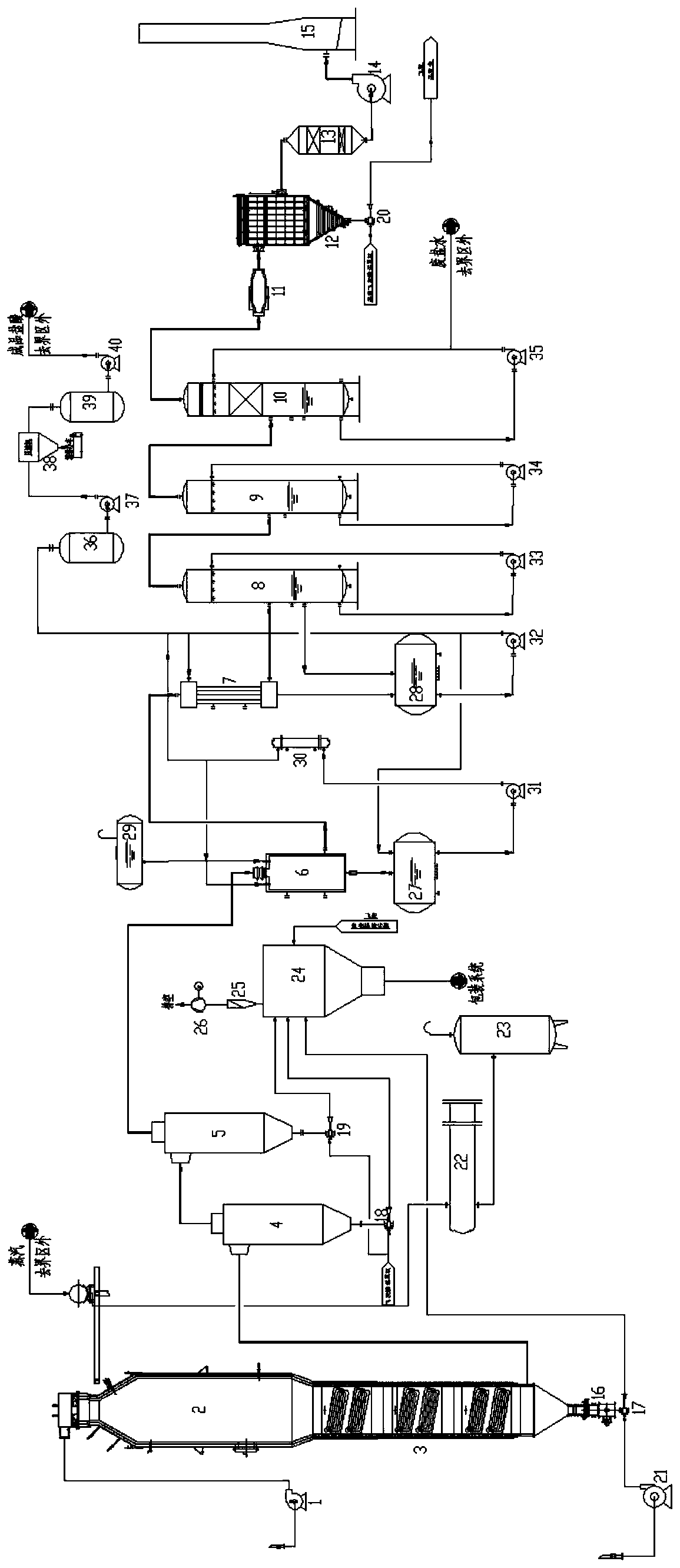

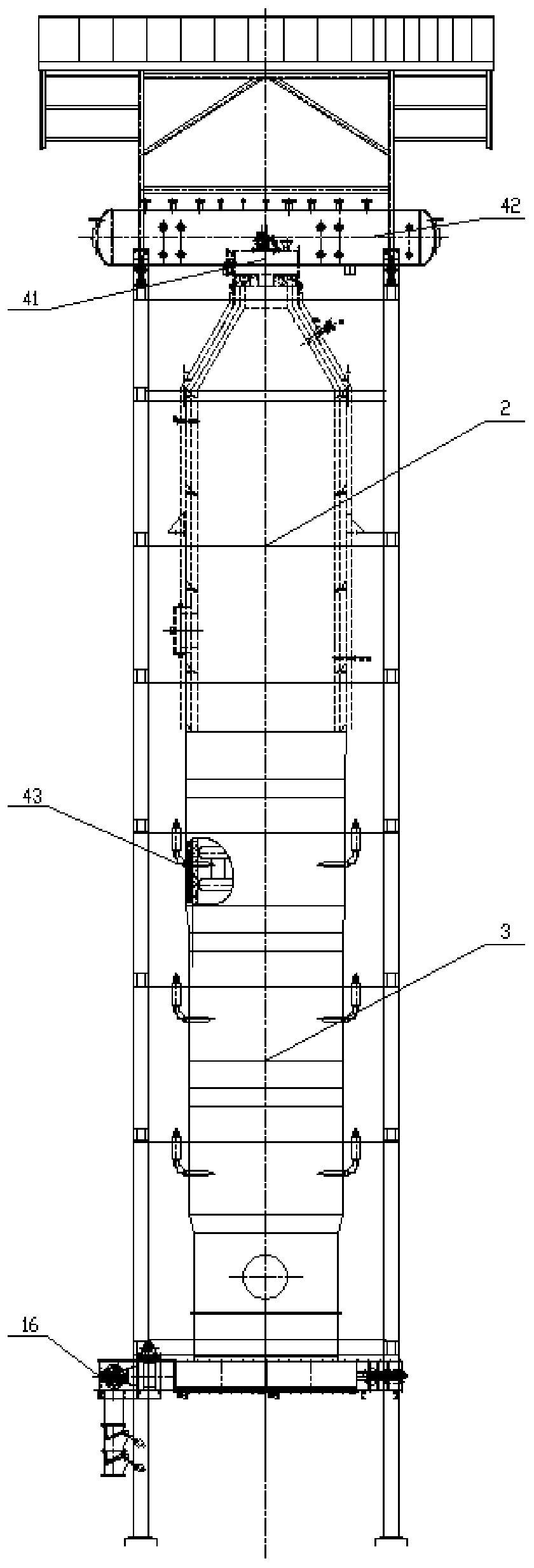

[0023] The present invention will be further described in conjunction with the accompanying drawings.

[0024] An incineration treatment device for waste gas and waste liquid in the organic silicon industry, used for incineration treatment of silicon-containing chlorine-containing waste gas and waste liquid in the production of organic silicon, the device includes a blower 1, an incinerator 2, a waste heat boiler 3, and a first cyclone dust collector 4, the second cyclone dust collector 5, the quenching tower 6, the falling film absorber 7, the primary water washing tower 8, the secondary water washing tower 9, the alkali washing tower 10, the pipeline heater 11, the bag filter 12, the activated carbon adsorption tower 13. Induced fan 14, chimney 15, fly ash conveying system (including water-cooled scraper machine 16, first Venturi conveyor 17, second Venturi conveyor 18, third Venturi conveyor 19, fourth Venturi conveyor 20, Roots blower 21), blowdown heat exchanger 22, blowd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com