Traceable pN-scale force value calibration device and method

The technology of a calibration device and calibration method is applied in the direction of measurement devices, optical devices, and the measurement of force balance force, which can solve problems such as difficulty in setting up an experimental platform, difficulty in reproducing, and deviation of results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

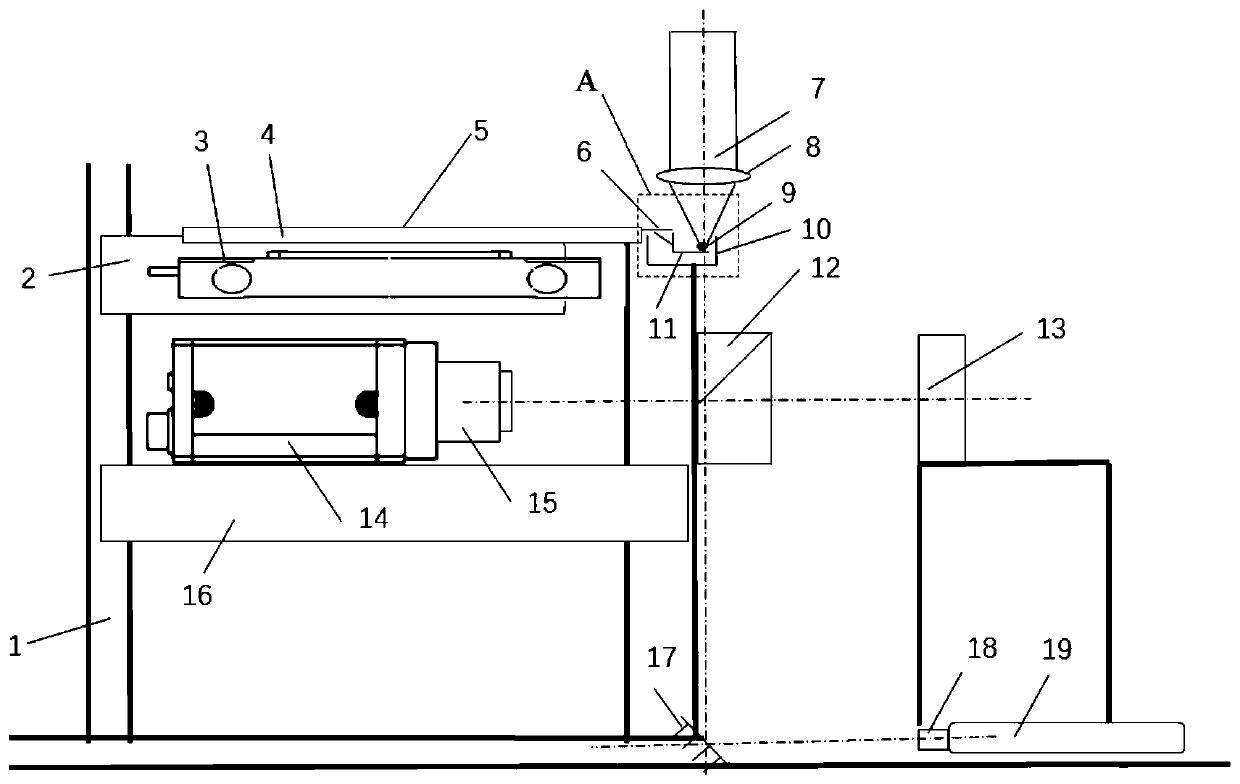

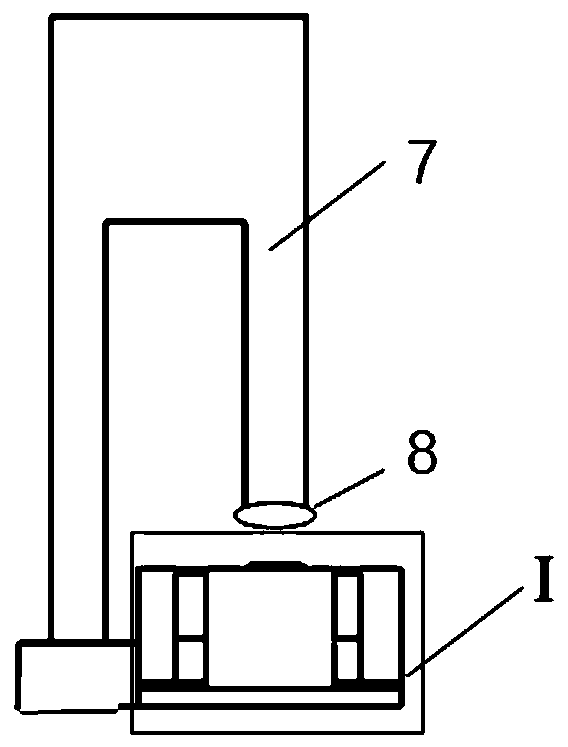

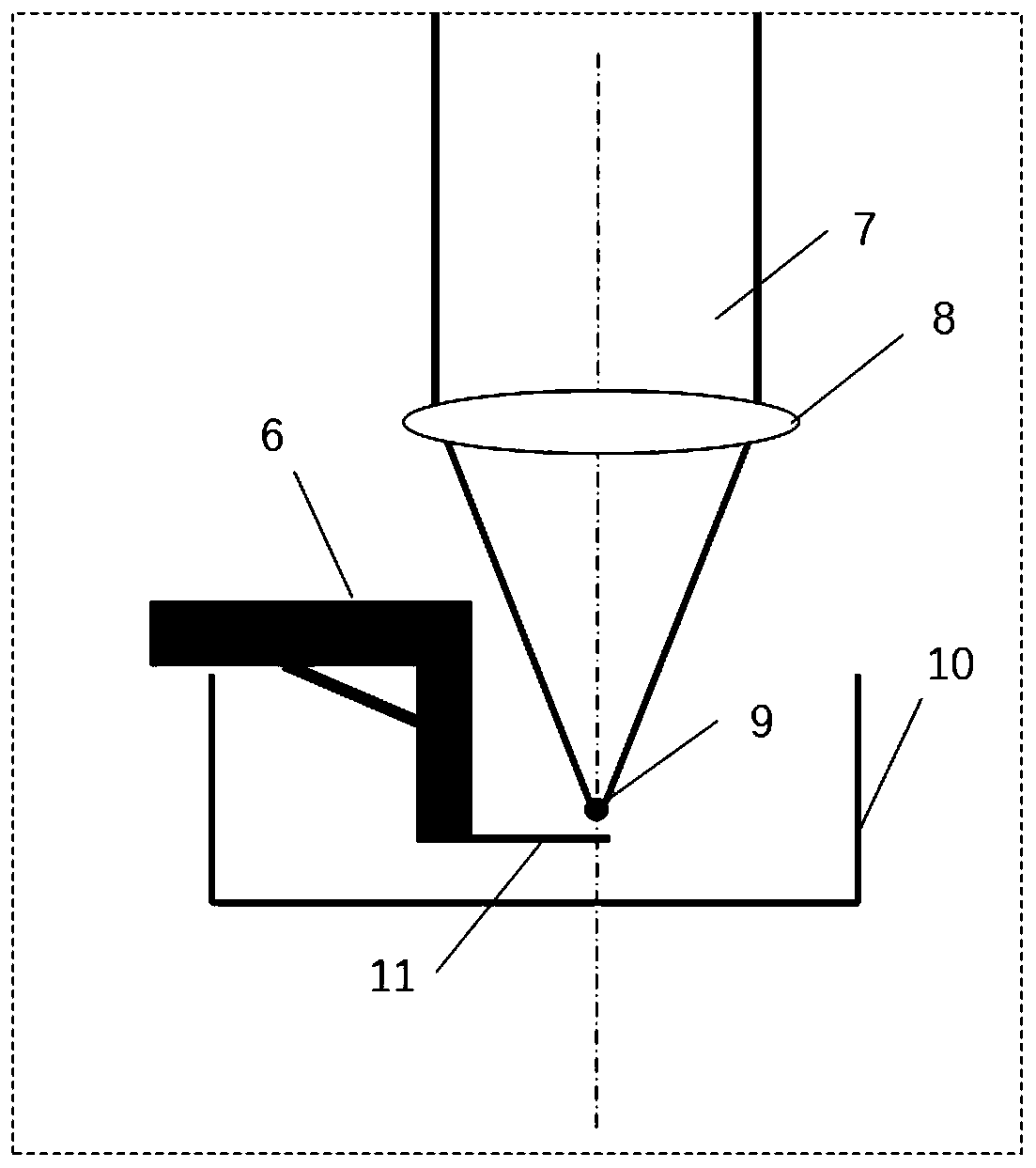

[0052] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0053] 1. Estimate the magnitude of light pressure

[0054] Normally, the optical tweezers system uses a 1064nm Nd:YAG laser, a linear polarization converter, and an objective lens with a large NA. The microsphere 9 part often uses micron-sized silicon balls or silicon dioxide balls, and the liquid environment is water.

[0055] The trapping force of optical tweezers on particles is generated from the change of momentum caused by the change of propagation direction when the beam with momentum is incident on the surface of the particle. According to Newton's second law, the binding force of optical traps can be obtained from the time change rate of momentum. According to Newton's second law law, the binding force of the optical trap can be exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com