A method for detecting the quality information of forgings in a die forging intelligent manufacturing production line

A technology of intelligent manufacturing and quality information, applied in the direction of program control, electrical program control, comprehensive factory control, etc., can solve the problems of insufficient multi-stage production quality control, low production detection accuracy, low efficiency, etc., and achieve high detection and identification High efficiency and accuracy, realize quality traceability, and reduce misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Examples of the invention are described in detail below, examples of which are shown in the accompanying drawings:

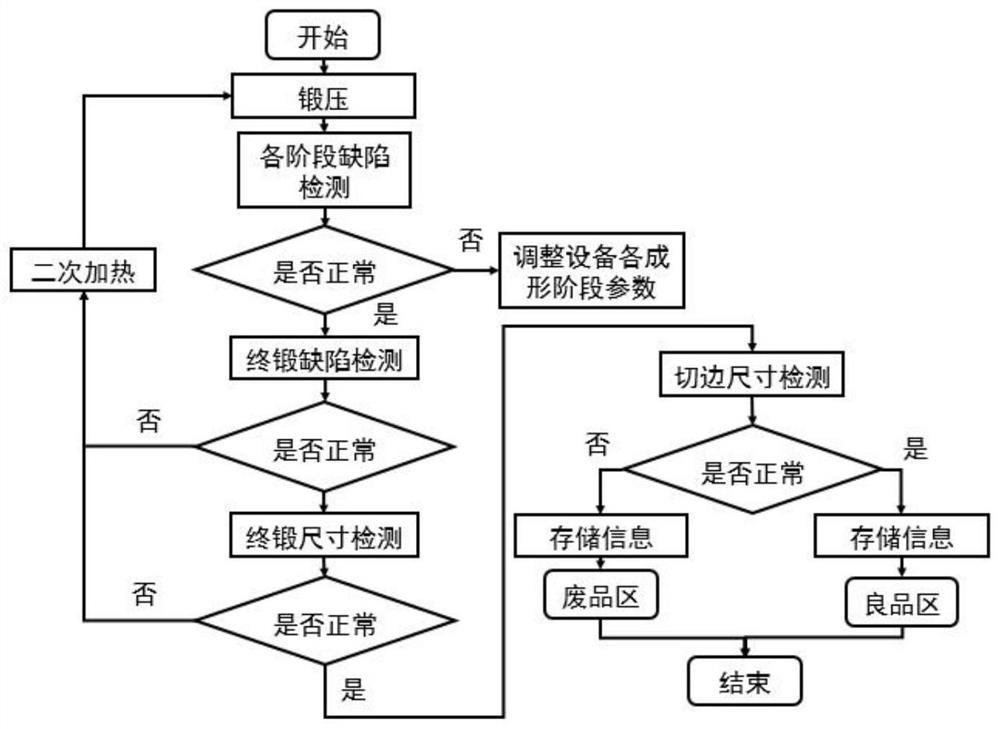

[0049] The implementation process of the present invention is as follows figure 1 As shown, the specific implementation process is as follows:

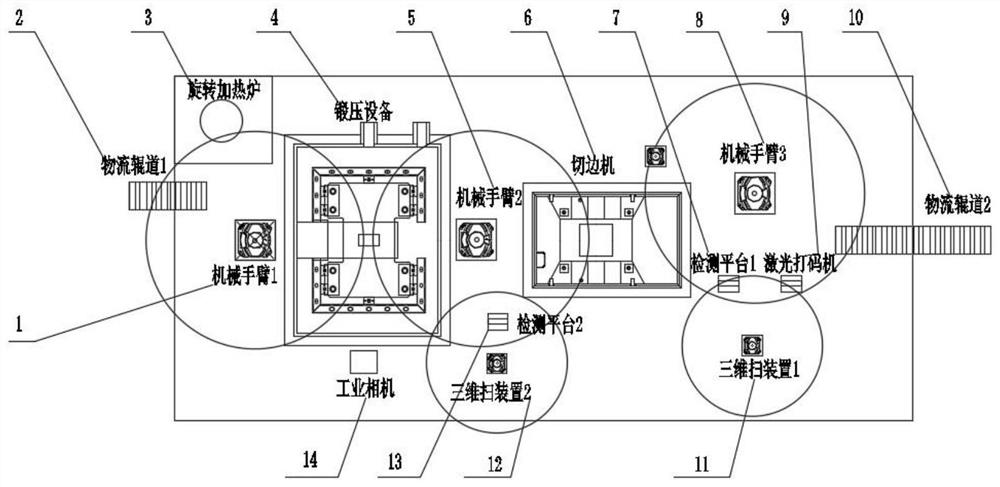

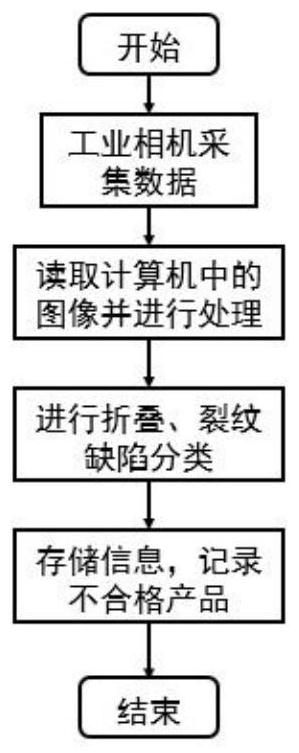

[0050] The implementation process of the die forging intelligent manufacturing production line: first, the billet is transported by the robot arm (1) into the rotary heating furnace (3) for heating through the logistics roller table A (2), and then transported by the robot arm A (1) into the forging equipment (4 ) for forging and forming, the forging is formed by multi-stage forging and forming by forging equipment, and after each forging and forming, the forging is inspected by an industrial camera (14) for defects; the defect modes mainly include three modes: folding, crack and normal. If the forging appears folded or cracked before forging, the forging press stops operation and checks and adjusts the forging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com