Power electronic wire and terminal fixed connection equipment and operation method

A technology for terminal fixing and connecting equipment, applied in the direction of tightening/insulating connectors, connections, parts of connecting devices, etc. Ends fall off and other problems, to achieve the same degree of compression, avoid defective products, and avoid falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

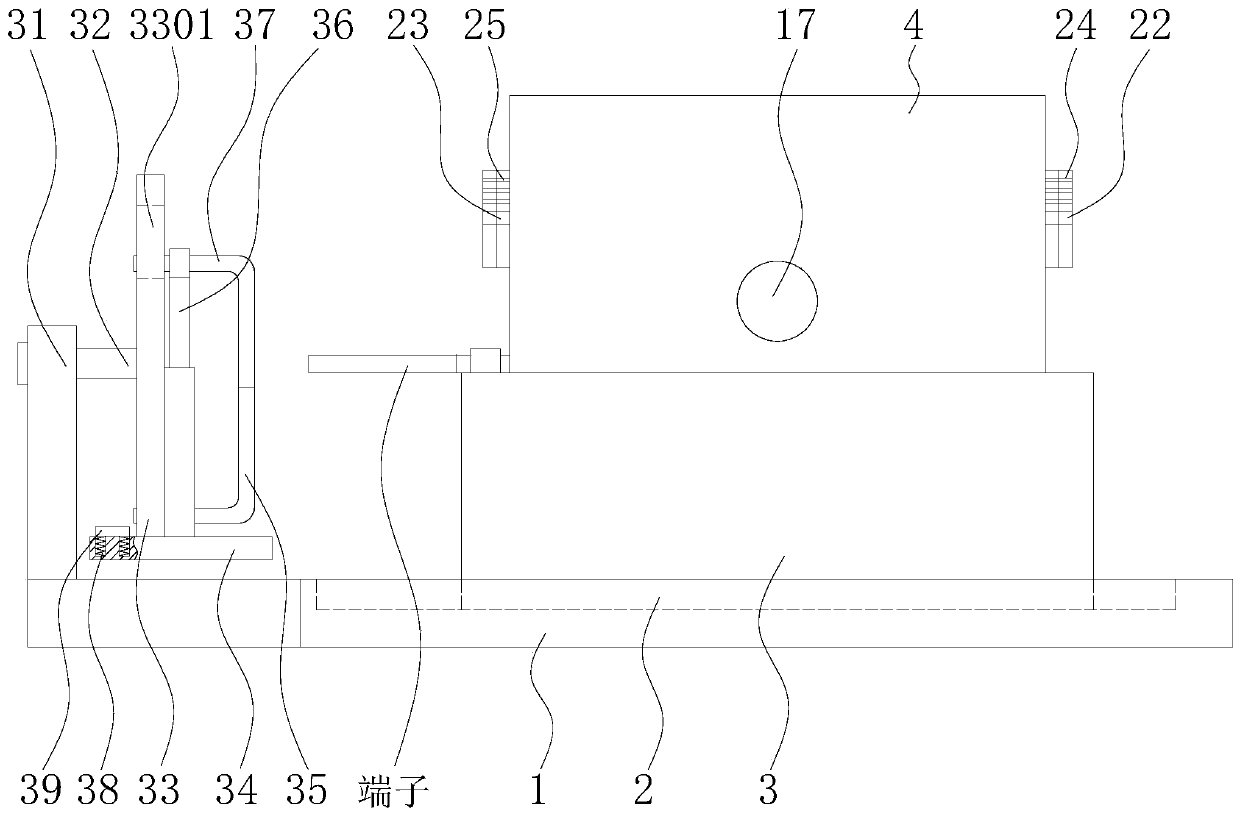

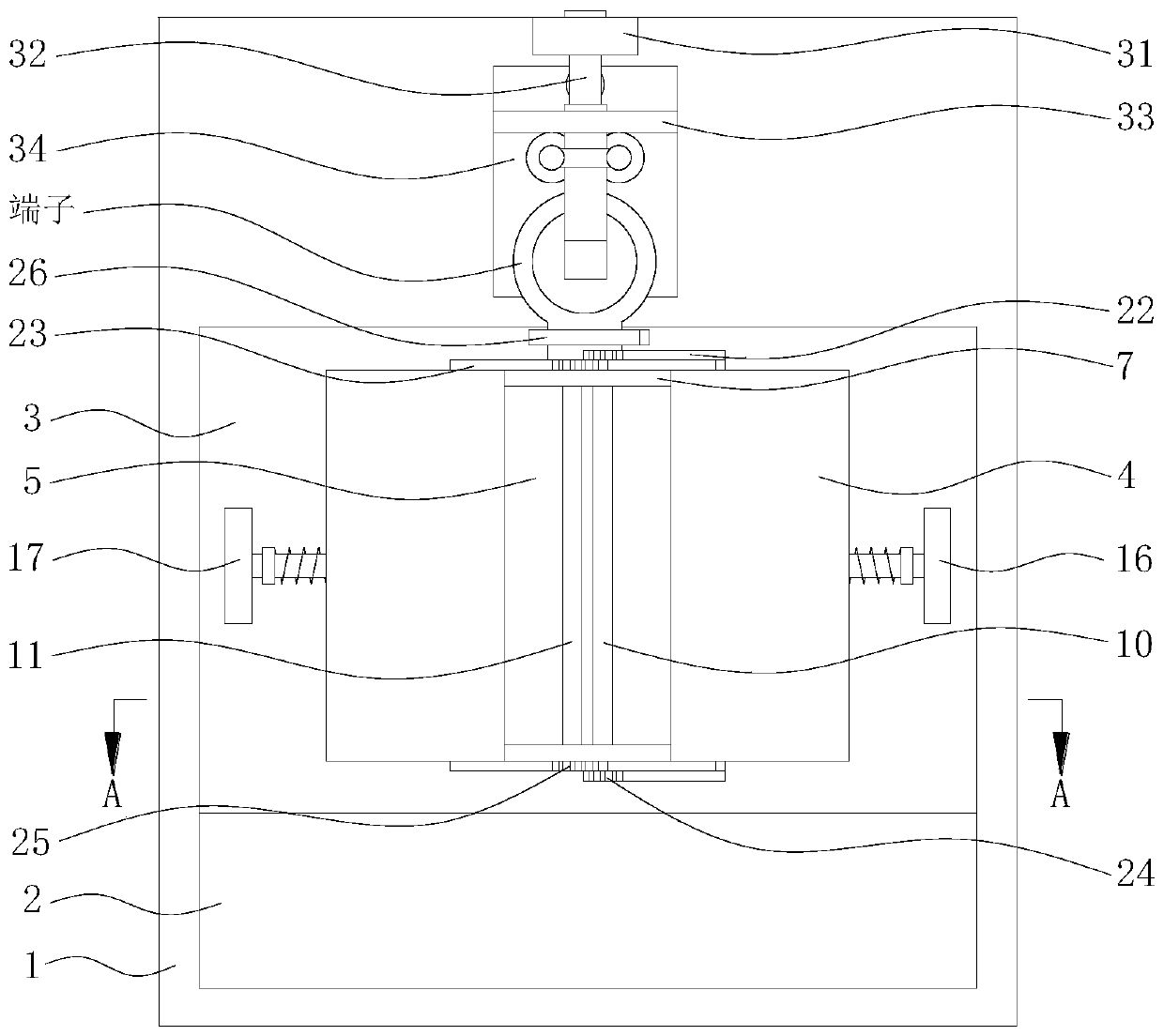

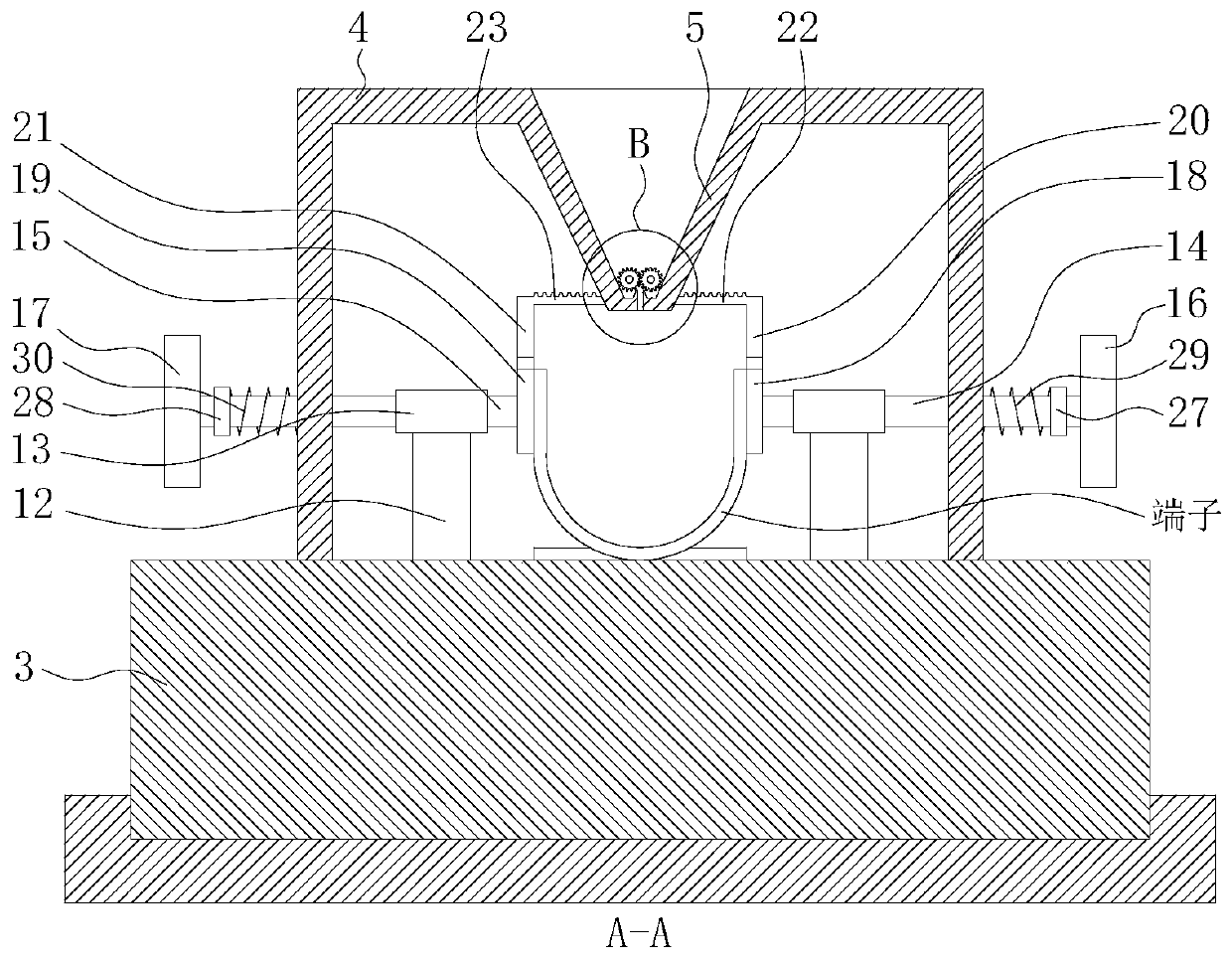

[0034] Such as Figure 1 to Figure 4 As shown, this embodiment provides a device for fixed connection between power electronic wires and terminals, where the terminal refers to a wire lug or other terminals similar to a wire lug, and the fixed connection refers to the fixed connection of two wires. The device includes a bottom plate 1, the upper surface of the bottom plate 1 is provided with a first chute 2, and a slider 3 is slidably fitted in the first chute 2. The upper surface of the slide block 3 is an iron horizontal plane and two symmetrical mounting frames 4 are vertically fixedly installed, and the longitudinal section of the mounting frame 4 is an inverted L-shape. Two baffle plates 5 are obliquely and fixedly installed on the top edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com