Raw material cleaning device for glutinous rice wine production

A cleaning device and technology for glutinous rice wine, which is applied in the direction of separating solids from solids with airflow, solid separation, filtration, etc., can solve the problems of production impact of glutinous rice wine, inability to clean dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

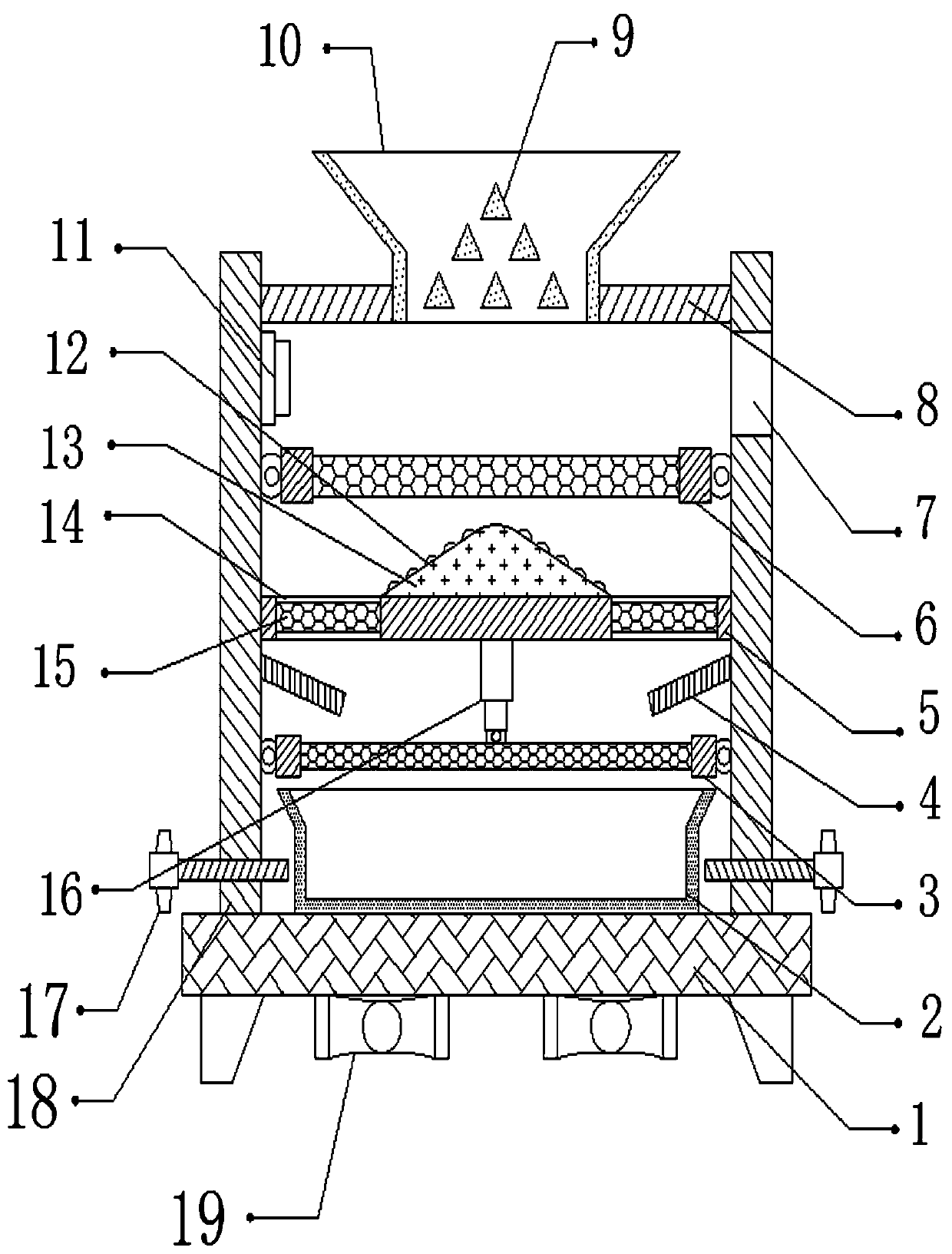

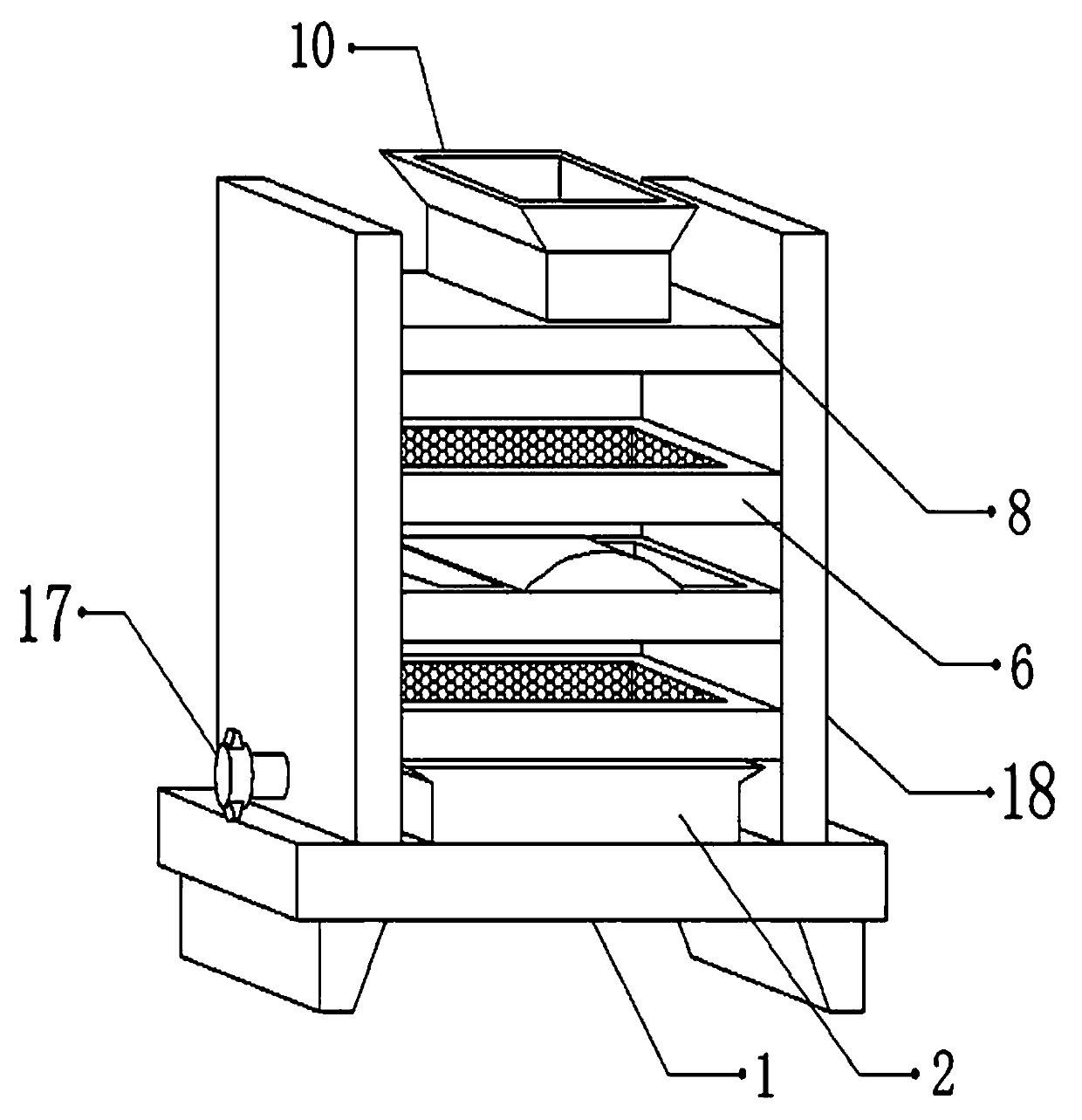

[0027] refer to Figure 1-2 , a raw material cleaning device for glutinous rice wine production, comprising a fixed seat 1, the two sides of the top outer wall of the fixed seat 1 are connected with connecting plates 18 by bolts, and the outer walls of the opposite sides of the two connecting plates 18 are connected by bolts Connected with a support plate 8, the top outer wall of the support plate 8 has a feed inlet, and the inner wall of the feed inlet is connected with a feed hopper 10 by bolts, and the inner wall of the feed hopper 10 is connected with a plurality of stoppers 9 by bolts, one One side of the outer wall of the connecting plate 18 near the top is connected with a fan 11 by bolts, the other connecting plate 18 has a dust removal port 7 on one side of the outer wall, and the opposite side outer walls of the two connecting plates 18 are connected by a hinge. The second filter screen 6 is provided with a collection box 2 on the top outer wall of the fixing base 1 ...

Embodiment 2

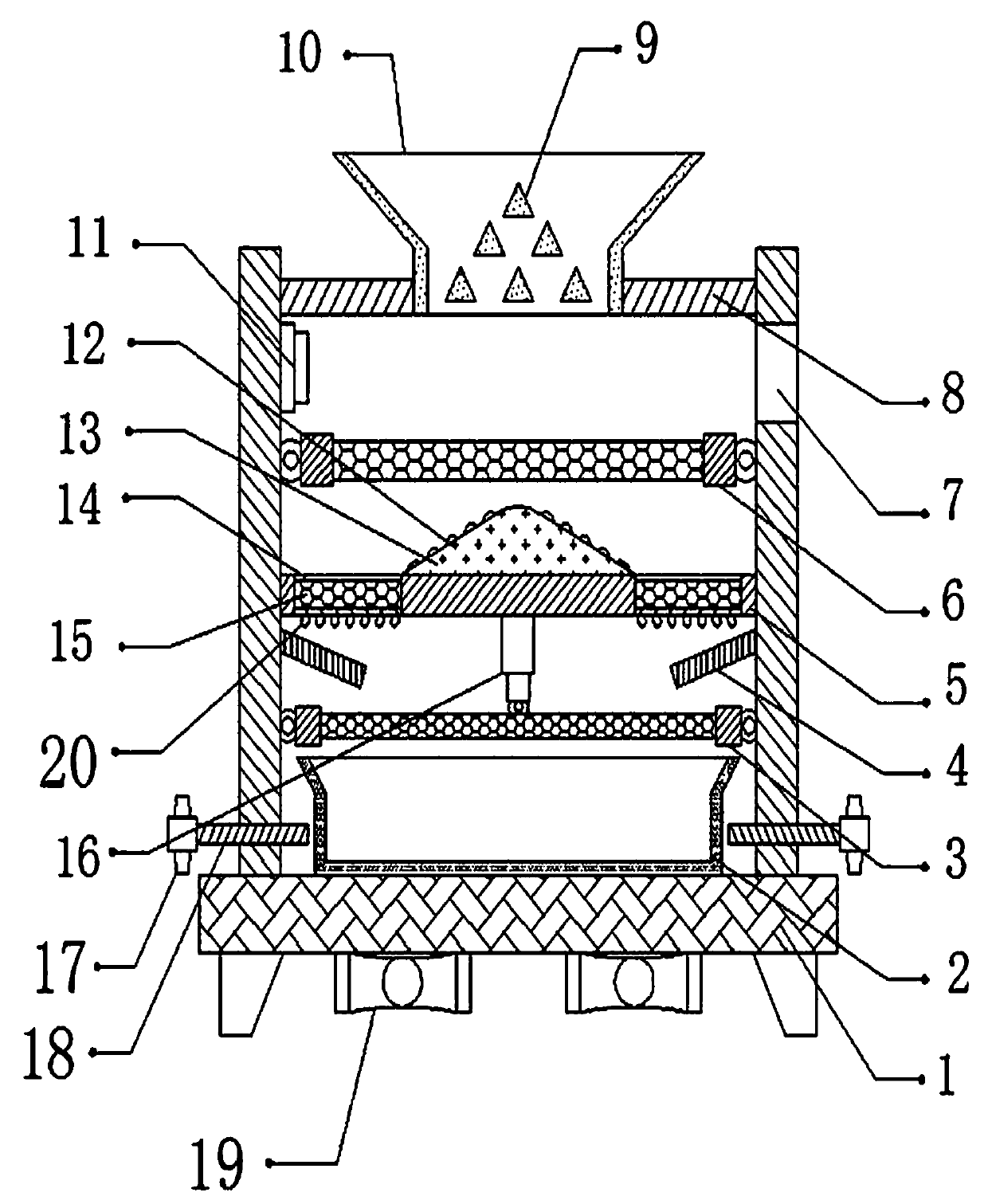

[0031] refer to image 3 , a raw material cleaning device for the production of glutinous rice wine. Compared with Embodiment 1, the outer walls of the bottom of the two filter buckets 15 in this embodiment are provided with hooks 20 distributed equidistantly.

[0032] Working principle: when in use, the raw materials that need to be screened are filled into the device through the feed pipe 10, and the falling speed of the raw materials can be slowed down by the stopper 9, and at the same time, the raw materials can be dispersed by the stopper 9 to prevent the accumulation of raw materials It is not convenient to screen together. The dust mixed in the raw materials can be cleaned by the fan 11. The dust will be discharged through the dust removal port 7, and the raw materials will fall into the second filter screen 6, and the raw materials will be preliminarily filtered through the second filter screen 6. Screening, the screened raw materials will fall on the drainage plate 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com