Induction coil copper pipe forming device

A molding device and induction coil technology, applied in the direction of molding tools, metal processing equipment, manufacturing tools, etc., to achieve the effect of beautiful eddy current loss, low labor intensity of workers, and small eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

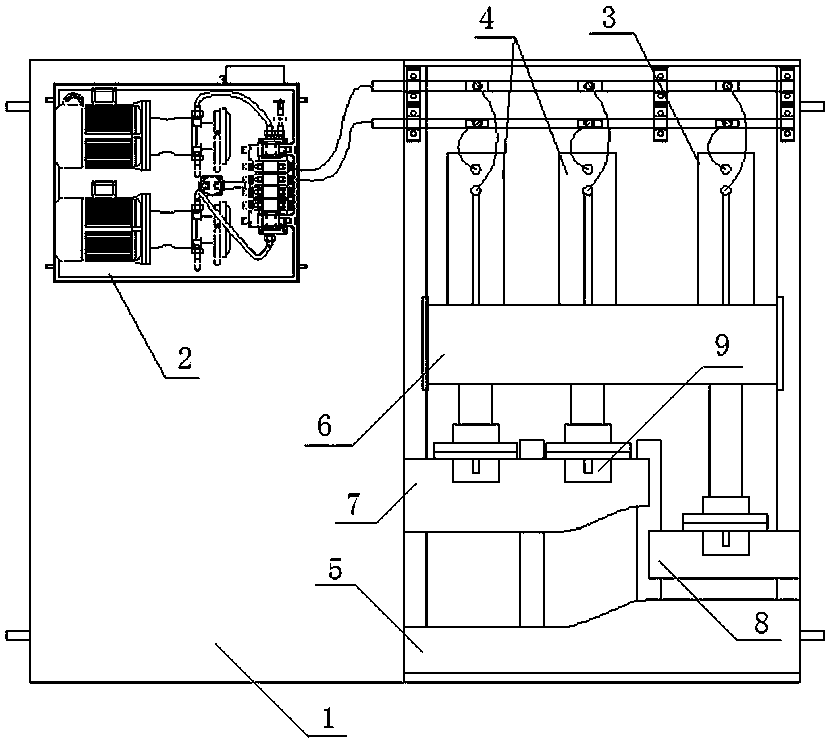

[0016] Such as figure 1 A kind of induction coil copper pipe forming device shown, comprises frame 1, fixed mold 5 that is installed on frame 1, is provided with hydraulic top fixed frame 6 on frame 1, is installed on hydraulic top fixed frame 6 Mold hydraulic jack 4, copper pipe fixed hydraulic jack 3, movable mold hydraulic jack 4 connected to movable mold 7, copper tube fixed hydraulic jack 3 connected to fixed block 8, bending arcs are set on fixed mold 5 and movable mold 7, and movable mold hydraulic pressure The top 4 and the copper pipe fixed hydraulic top 3 are connected to the hydraulic pump station 2 .

[0017] When working, first replace the mold according to the size of the copper tube, install the fixed mold and the movable mold, then use the copper tube to fix the hydraulic jack 3, press the copper tube, and then drive the hydraulic jack 4 of the movable mold to press.

Embodiment 2

[0019] As a specific structural design of Embodiment 1, two hydraulic jacks 4 of the movable mold are arranged in parallel. In order to ensure the bending effect, we designed two movable mold hydraulic jacks 4, this design, after the copper tube is fixed by the hydraulic jack 3, it is easier to bend into the desired shape.

[0020] The movable mold 7 is connected with the hydraulic rods of the two movable mold hydraulic jacks 4 through the mold mounting seat 9 .

[0021] The copper tube fixed hydraulic jack 3 is connected to the fixed block 8 through the mounting seat.

[0022] A chute is set on the frame 1 under the movable mold 7 and the fixed block 8, and a slide block is set on the movable mold 7 and the fixed block 8 on the chute. This structural design allows the movement of the movable mold 7 and the fixed block 8 to be more precise and run more smoothly.

[0023] The bending radian is set on the movable mold 7 at the adjacent part of the movable mold 7 and the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com