An automatic fitting equipment for dust-proof protective sleeves for metal pipe fittings

A technology of metal pipe fittings and automatic assembly, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of complex work engineering, large floor space, inconvenient operation, etc., and achieve synchronous movement, stable structure, and energy saving The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

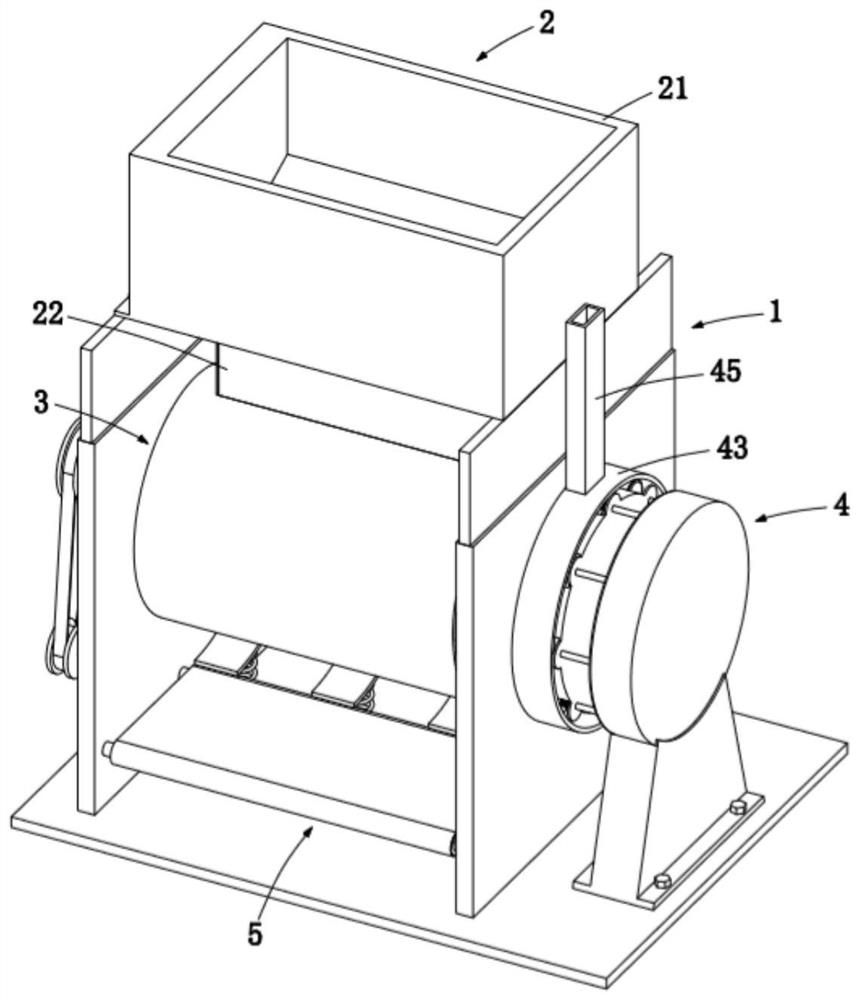

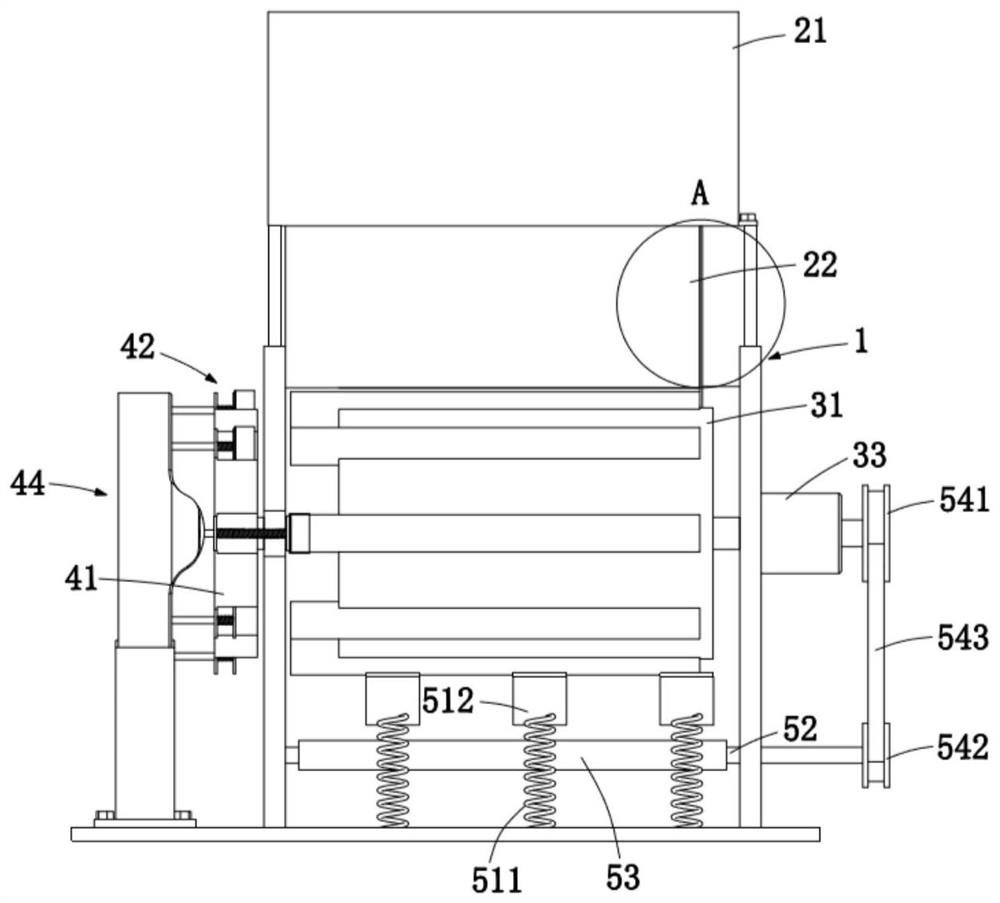

[0042] Such as Figure 1 to Figure 9 As shown in the figure, an automatic dust-proof protective cover equipment for metal pipe fittings, including:

[0043] Rack 1;

[0044] Feeding assembly 2, the feeding assembly 2 is arranged on the upper end of the frame 1, it includes a material storage box 21 installed on the inner wall of the frame 1, and a storage box 21 arranged at the bottom of the storage box 21 The feeding chute 22;

[0045] The transmission part 3, the transmission part 3 is arranged below the feed assembly 2 and installed on the inner wall of the frame 1, which includes a feed roller 31 rotatably mounted on the inner wall of the frame 1, and the The feeding roller 31 is coaxially arranged around it and is installed on the limit frame a32 on one side of the inner wall of the frame 1, and is arranged on one side of the frame 1 and is connected to one end of the feeding roller 31. The biaxial motor 33;

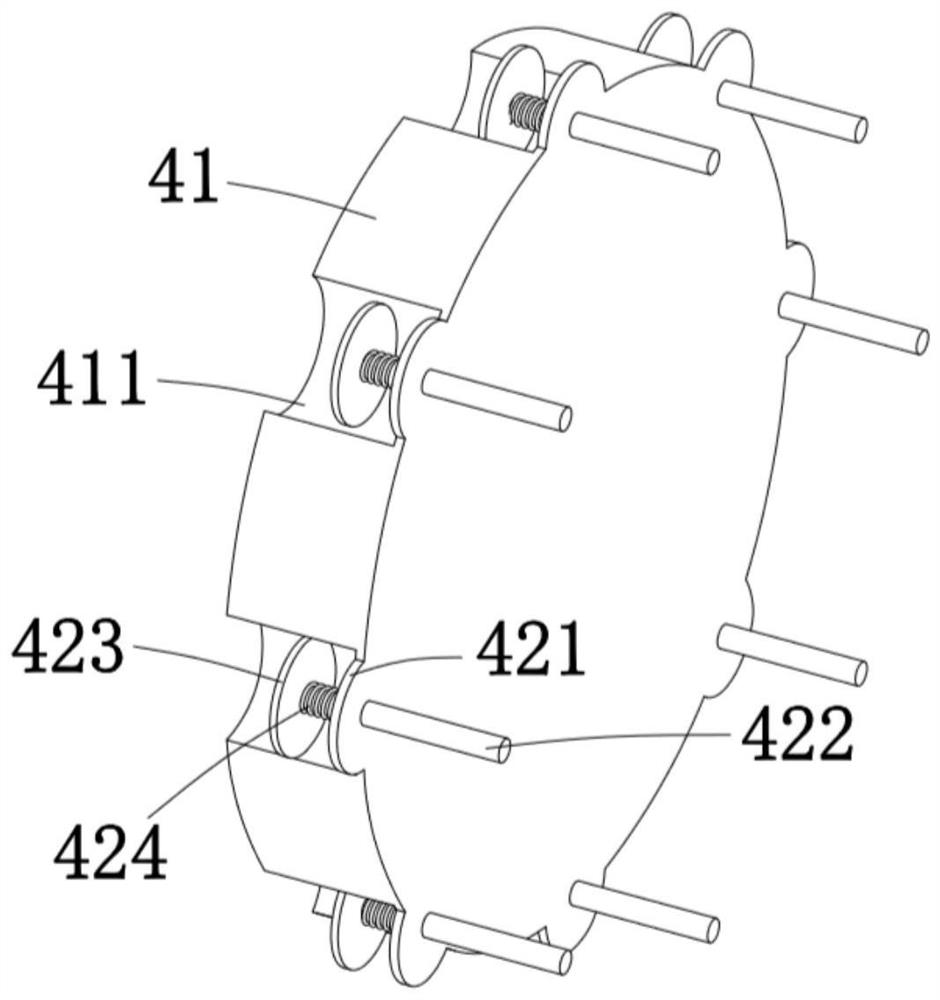

[0046] The automatic cover part 4, the automatic cover part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com