A kind of deburring equipment for hollow bridge processing

A hollow bridge and burr technology, which is applied in the field of deburring equipment for hollow bridge processing, can solve the problems of low efficiency and manpower consumption, and achieve the effects of quality assurance, high work efficiency, and stable deburring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

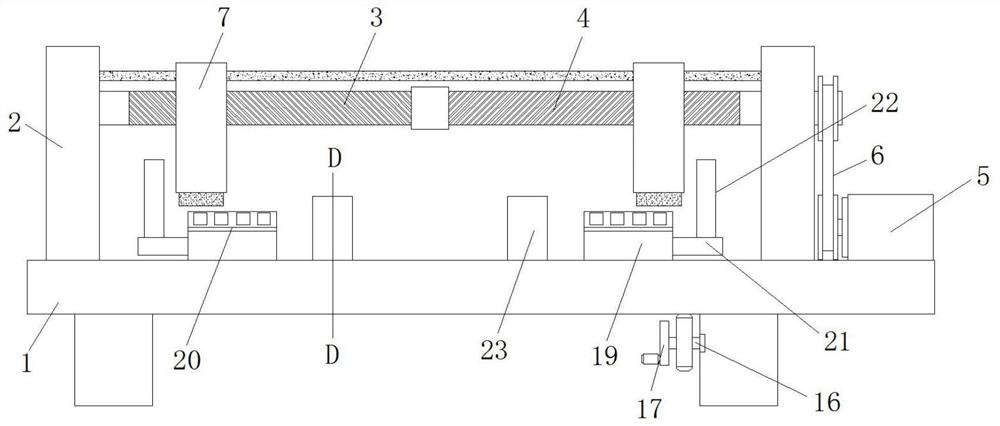

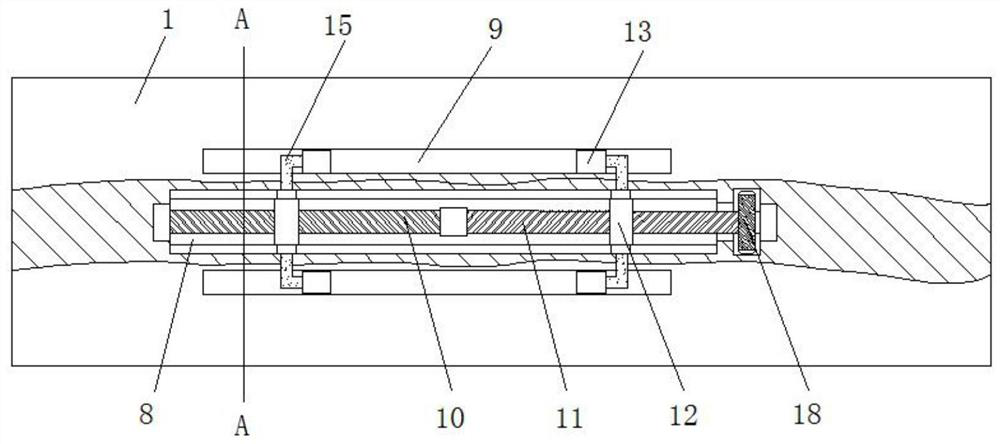

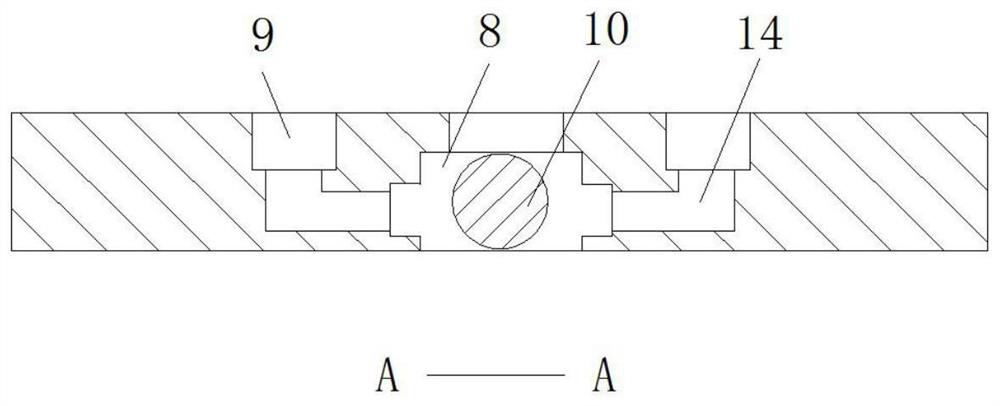

[0032] refer to Figure 1-7, a kind of deburring equipment for hollow bridge processing, comprising a machine 1, a support plate is fixed on both sides of the lower end of the machine 1, a support seat 2 is fixedly connected to both sides of the upper end of the machine 1, and two support seats 2 The side close to the upper end is respectively connected to the first screw 3 and the second screw 4 through rolling bearings, and the screw threads of the first screw 3 and the second screw 4, as well as the third screw 10 and the fourth screw 11, have opposite screw threads, and the machine 1 A servomotor 5 is also fixed on one side of the upper end surface, and the output end of the servomotor 5 is connected with the screw rod 2 4 through the transmission device 6. The outer wall of the screw rod 1 3 and the screw rod 2 4 is fixedly connected with a deburring device 7 for deburring. The burr device 7 comprises a mounting seat 701, and the mounting seat 701 is threadedly connected ...

Embodiment 2

[0035] Such as figure 1 and 7 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the bridge fixing device 23 includes a support seat 2301, and the support seat 2301 is fixed on the sliding block 13, and the upper part of the support seat 2301 is screwed. Rotating rod 2302, the two ends of rotating rod 2302 are fixedly connected with extruding plate 1 2303 and rotating handle 2304 respectively, and extruding plate 1 2303 is close to the side of the center of machine table 1, and the end of extruding plate 1 2303 is close to the center of machine table 1. A cylindrical barrel 2305 is fixedly connected, and the inner wall of the cylindrical barrel 2305 is slidably connected with a pressure rod 2306. A spring 2307 is fixed between the pressure rod 2306 and the bottom surface of the cylindrical barrel 2305. One end of the pressure rod 2306 is fixedly connected with an extrusion plate 2308. A rubber head 2309 is fixed on the side of the second plate 2308 a...

Embodiment 3

[0038] Such as Figure 7 As shown, this embodiment is basically the same as Embodiment 1. Preferably, there are multiple cylindrical barrels 2305 that are evenly distributed on the end surface of the extruded plate 1 2303 .

[0039] In this embodiment, a plurality of cylindrical barrels 2305 are provided to ensure that the rubber head 2309 is pressed evenly on the bridge frame, thereby ensuring the stability of the bridge frame during deburring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com