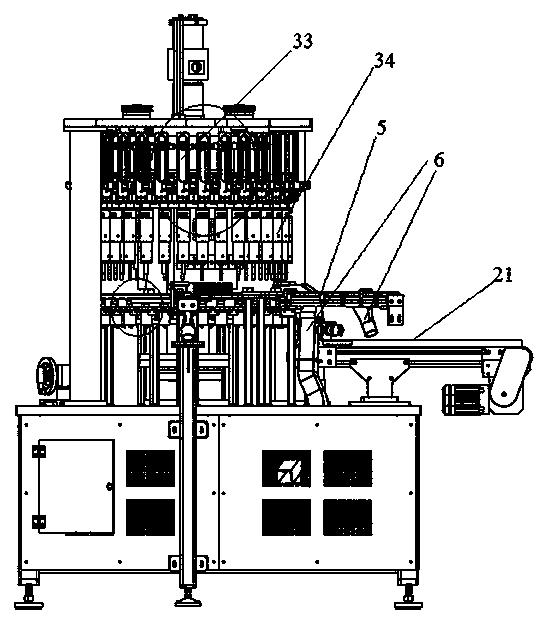

Bottle cap and silicone valve assembling machine

A silicone valve and assembly machine technology, which is applied to household components, household appliances, and other household appliances. It can solve the problems of difficult inspection of finished products, environmental pollution in the workshop, and breakage, so as to improve production efficiency, protect the environment in the workshop, and ensure airtightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further elaborated.

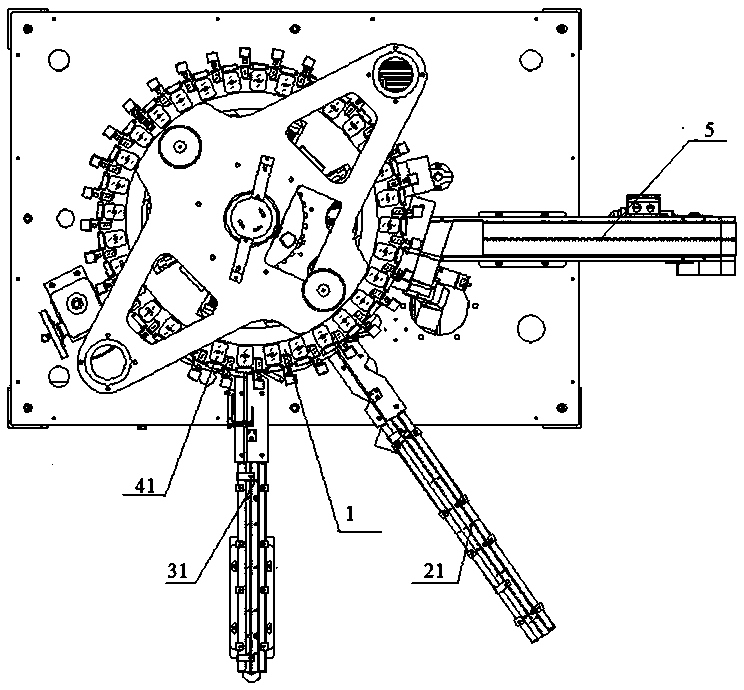

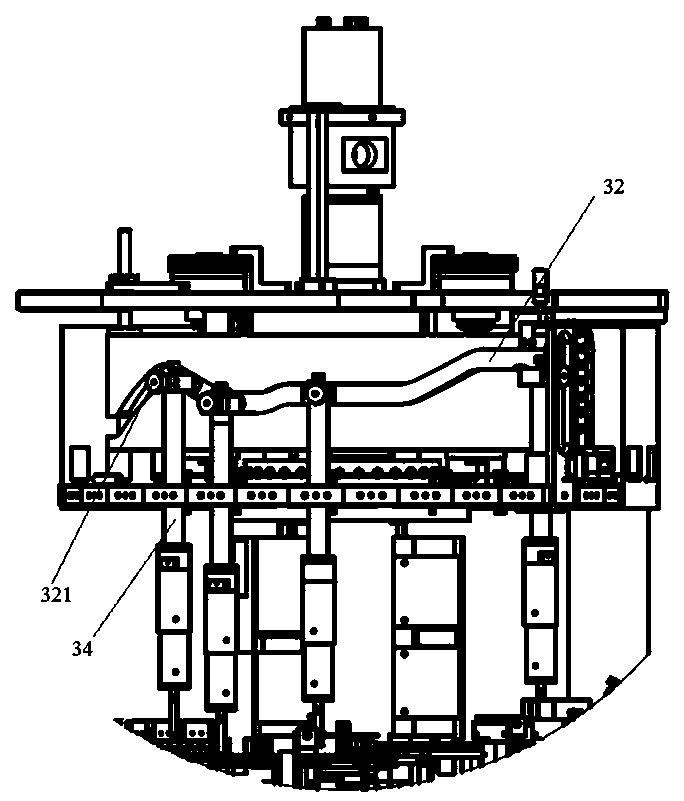

[0040] First, combine the Figure 1~7 The bottle cap silicone valve assembly machine according to the embodiment of the present invention is used for assembling the silicone valve of the bottle cap, and has a wide range of application scenarios.

[0041] Such as Figure 1~2 As shown, the bottle cap silicone valve assembly machine of the embodiment of the present invention has an annular turntable 1, a valve seat transfer module, a silicone valve transfer module, a hot melt assembly module, and a bottle cap output track. Among them, the circular turntable 1 is driven to rotate by a motor; the valve seat transmission module includes a valve seat input track 21 connected with the circular turntable 1 and a plurality of valve seat delivery seats 22, and a plurality of valve seat delivery ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap