Printing processing device for konjac packaging food bag

A technology for processing devices and food bags, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of decreased printing effect, easy generation of static electricity, indeterminate mottles, electrostatic burr phenomenon, etc., to improve stability and improve printing. effect, the effect of improving the leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

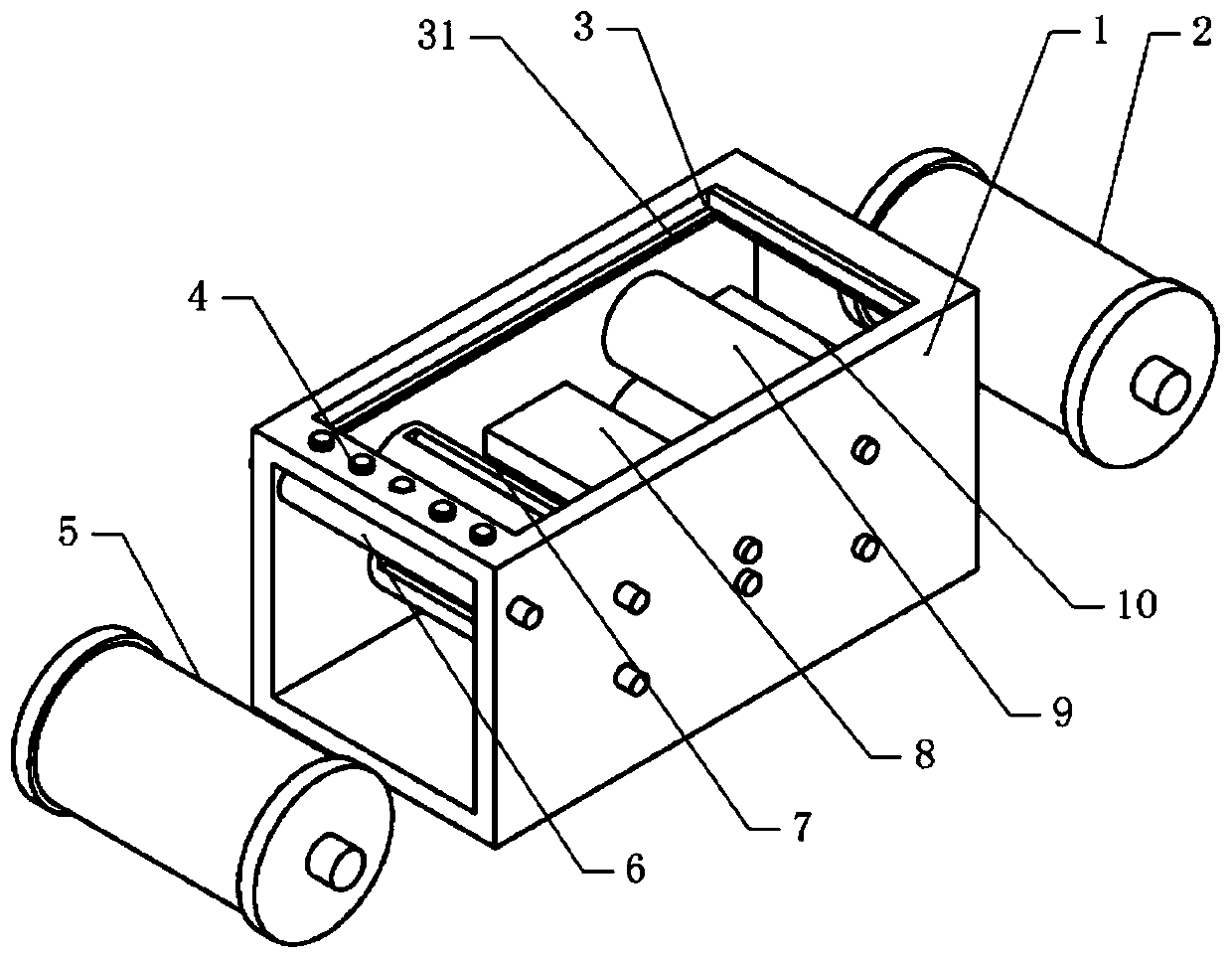

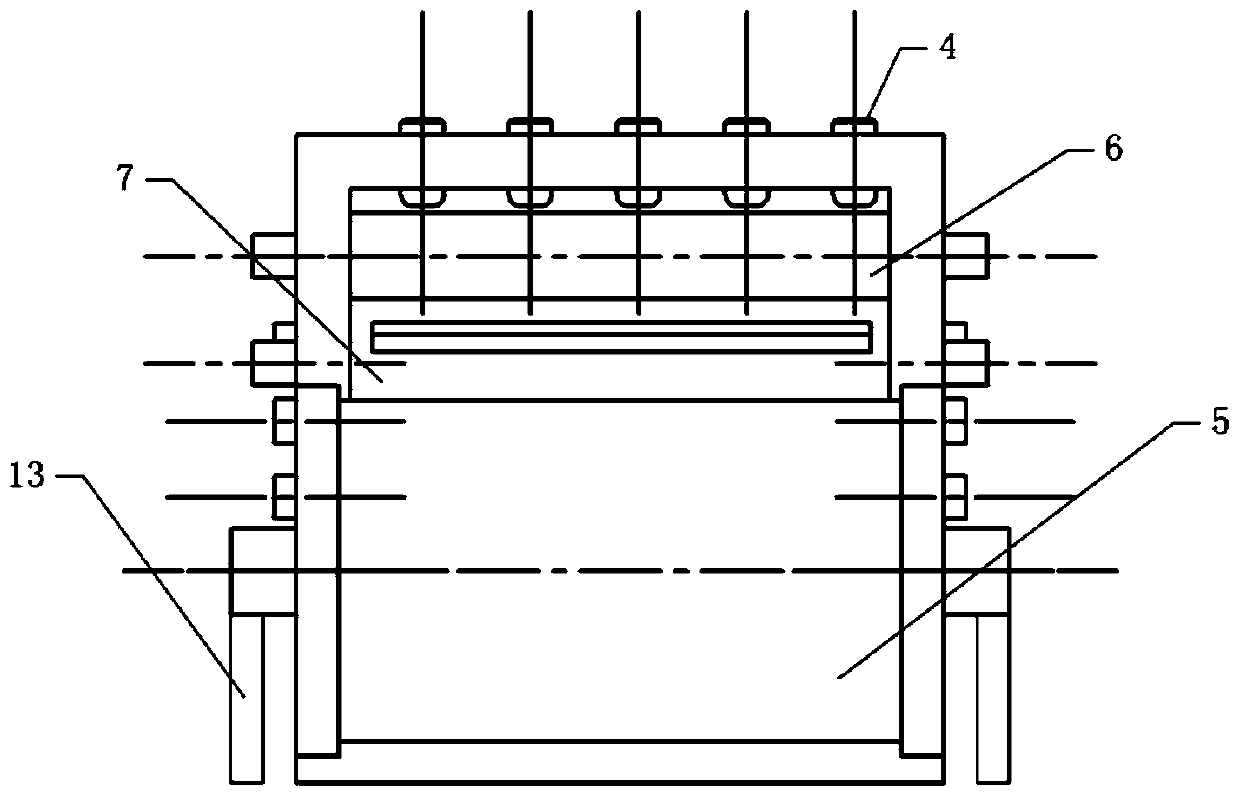

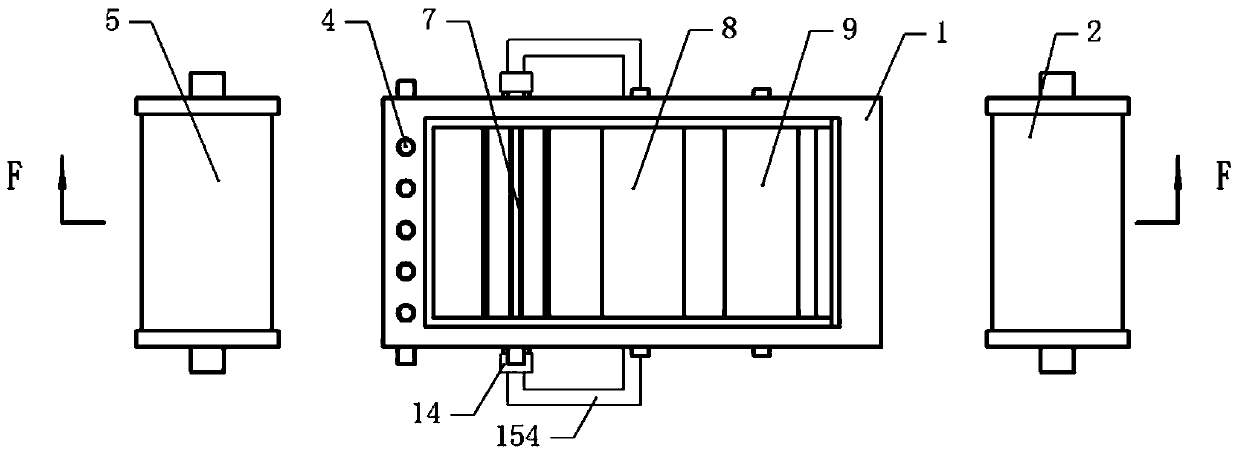

[0042] Basic as attached figure 1 Shown, a kind of printing and processing device of konjac packaged food bag comprises from left to right and comprises discharging roller 5, printing box 1 and winding roller 2 successively, and winding roller 2 is wound with sufficient packaging bag 11. combined with figure 2 As shown, the winding roller 2 and the discharging roller 5 are all rotatably mounted on the frame 13, and the winding roller 2 and the discharging roller 5 are respectively driven by two unidirectional motors (not shown in the figure).

[0043] as attached image 3 And attached Figure 4 Shown, the top wall of printing box 1 has window, is provided with the baffle plate 3 that is connected with printing box 1 rotation in the window, is provided with the placement plate 31 that is welded and fixed on the printing box 1 below the baffle plate 3, and the placement plate 31 A buffer layer is bonded on the top wall, and the buffer layer is made of rubber in this embodime...

Embodiment 2

[0058] The difference between embodiment two and embodiment one is that, as attached Figure 6 And attached Figure 7 As shown, the air outlet of the first pump assembly pump is connected to an upper dust removal box 151 through a pipeline, and water is housed in the upper dust removal box 151. The air curtain pipe 16 on the box 1, the communicating place of the pipeline and the upper dust removal box 151 is located above the liquid level.

[0059] The air outlet of the second pump assembly is connected to the lower dust removal box 152 through a pipeline, and is located below the fixed roller. The upper part of the lower dust removal box 152 has a tapered opening in longitudinal section, and a liquid inlet unit is fixed in the opening by fastening bolts. To the valve 153 , the liquid inlet check valve 153 communicates with the bottom of the lower dust removal box 152 , and the ink in the opening enters in the lower dust removal box 152 through the liquid inlet check valve 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com