Cementing material containing large amount of waste incineration fly ash and slag, and preparation method and application thereof

A technology of waste incineration fly ash and cementitious materials, applied in the field of building materials, can solve the problem of adding too much activator, etc., and achieve the effects of high utilization rate, avoid corrosion, and reduce the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 4

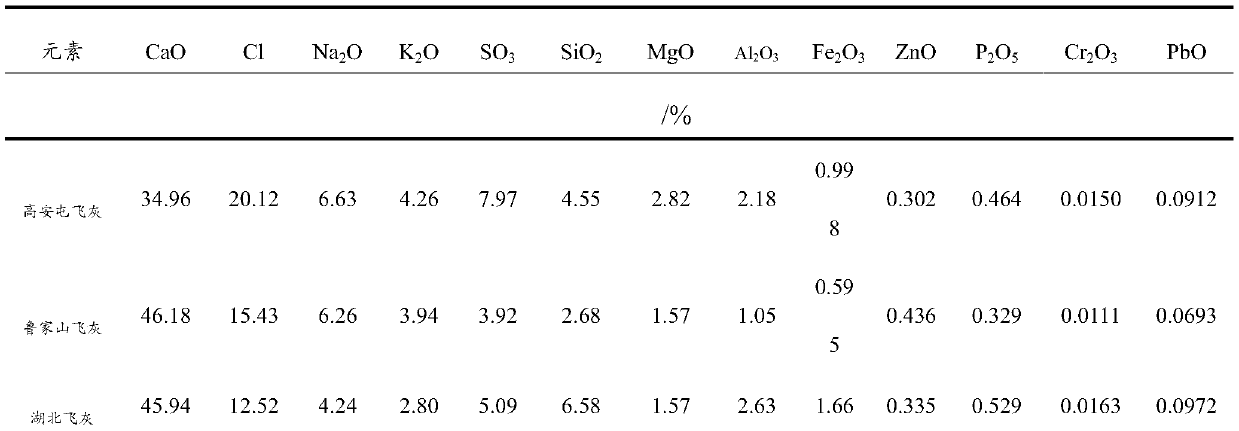

[0044] The method for preparing cementitious material with a large amount of waste incineration fly ash in 4 embodiments, which consists of the following components by mass percentage: 20-35% of waste incineration fly ash (respectively from 4 incineration power plants: Beijing Gaoantun, Beijing Lujiashan, a factory in Sichuan, a factory in Hubei), S95 slag powder 55-70%, desulfurization gypsum 10%.

[0045] Among them, the chemical composition of fly ash, S95 slag powder and desulfurized gypsum is shown in Table 1. The detection method is: X-ray fluorescence spectroscopic analysis (XRF), using XRF-1800 X-ray fluorescence spectrometer to measure secondary X-rays for material composition analysis.

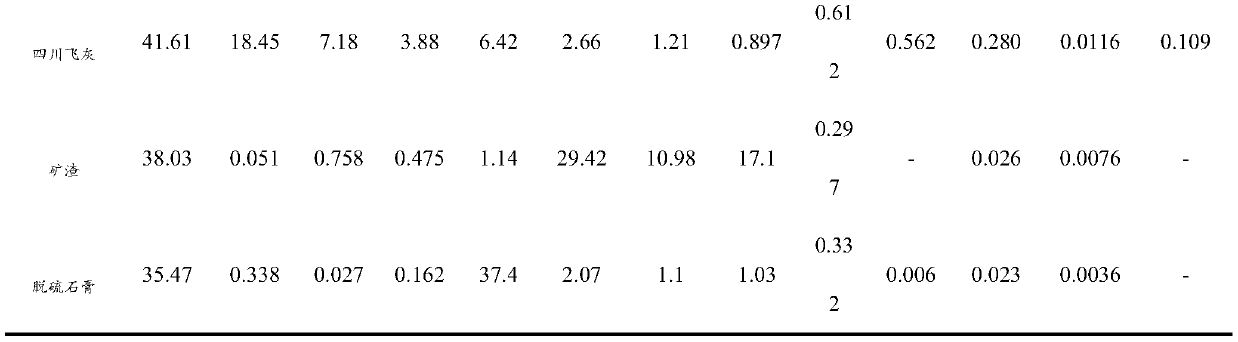

[0046] Table 2 shows the heavy metal leaching concentrations of four types of waste incineration fly ash and S95 slag powder.

[0047] After pouring and curing to different ages, the compressive strength test and leaching toxicity test are carried out. The test methods are:

[0048]...

Embodiment 5 to 8

[0054] The method for preparing cementitious material with a large amount of garbage incineration fly ash of 4 embodiments, which is composed of the following components by mass percentage: 35-50% of garbage incineration fly ash (from 4 incineration power plants respectively: Beijing Gaoantun, Beijing Lujiashan, Sichuan, Hubei), S95 slag powder 40-55%, desulfurization gypsum 10%.

[0055] Among them, the chemical composition and source of waste incineration fly ash, S95 slag powder and desulfurized gypsum are the same as in Example 1.

[0056] After being poured and molded, it was maintained to different ages for compressive strength test and leaching toxicity test. The test method is the same as that of Example 1, and the test results are shown in Tables 3 and 4.

Embodiment 9 to 12

[0058] The method for preparing cementitious material with a large amount of waste incineration fly ash in 4 embodiments, which is composed of the following components by mass percentage: 50-60% of waste incineration fly ash (respectively from 4 incineration power plants: Beijing Gaoantun, Beijing Lujiashan, Sichuan, Hubei), S95 slag powder 30-40%, desulfurization gypsum 10%.

[0059] Among them, the chemical composition and source of waste incineration fly ash, S95 slag powder and desulfurized gypsum are the same as in Example 1.

[0060] After being poured and molded, it was maintained to different ages for compressive strength test and leaching toxicity test. The test method is the same as that of Example 1, and the test results are shown in Tables 3 and 4.

[0061] Table 2 Leach concentration of heavy metals in four kinds of waste incineration fly ash and slag (ug / L)

[0062]

[0063]

[0064] Table 3 compressive strength of clean pulp test block

[0065]

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com