Fabricated concrete frame joint and construction method thereof

A concrete and prefabricated technology, which is applied in the direction of construction and building construction, can solve the problems of increased rigidity of joint parts, high cost, and change of stirrup size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

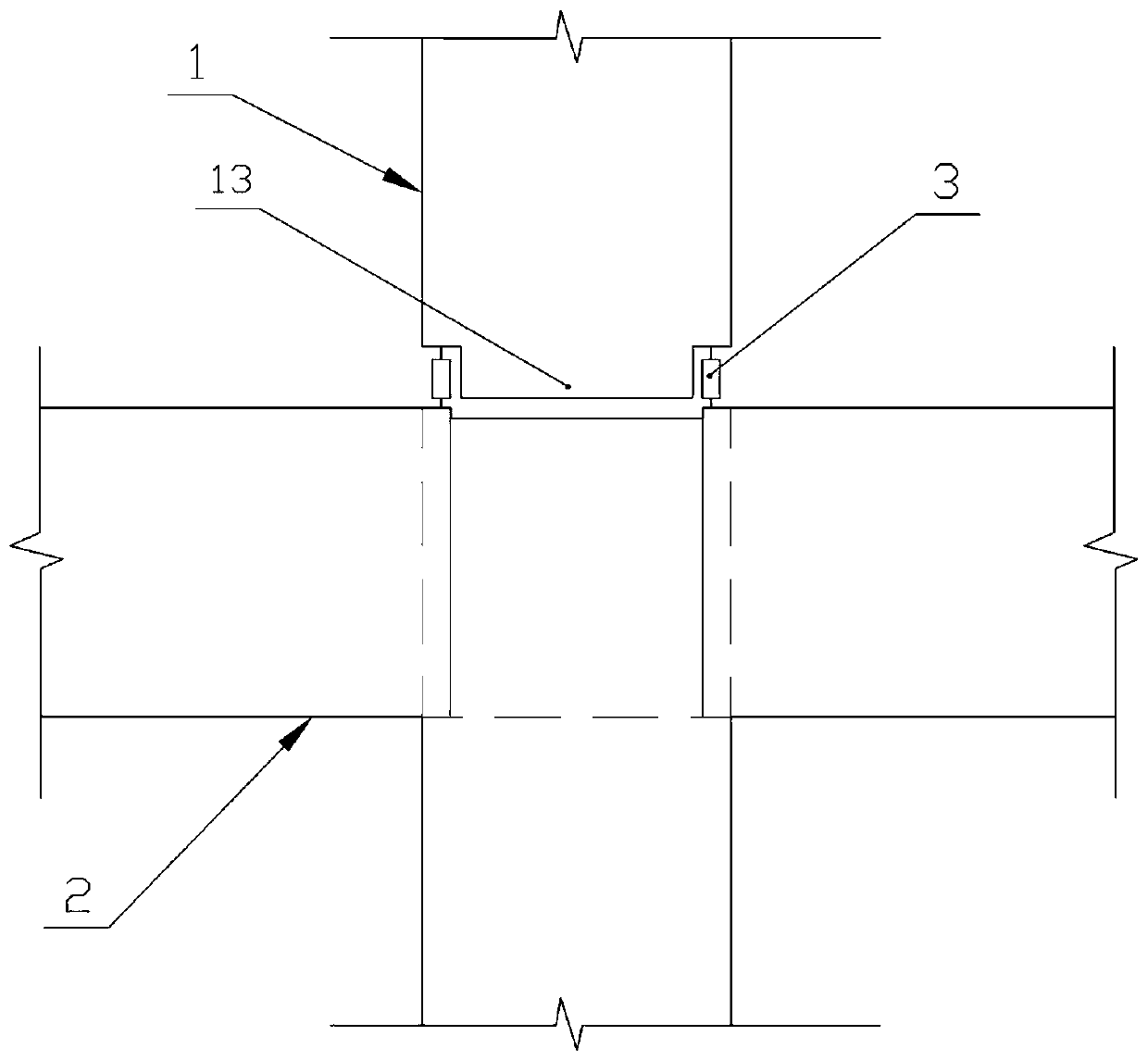

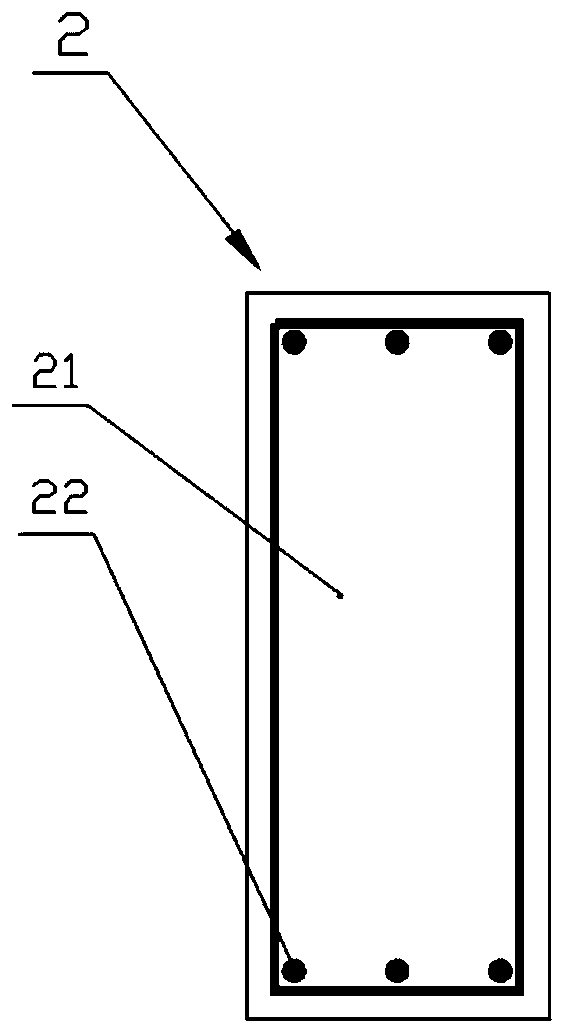

[0034] Preferred embodiment one, such as figure 1 As shown, the prefabricated concrete frame node disclosed in this embodiment includes a prefabricated column 1 and a prefabricated beam 2 , and the upper and lower prefabricated columns are connected through a threaded sleeve 3 .

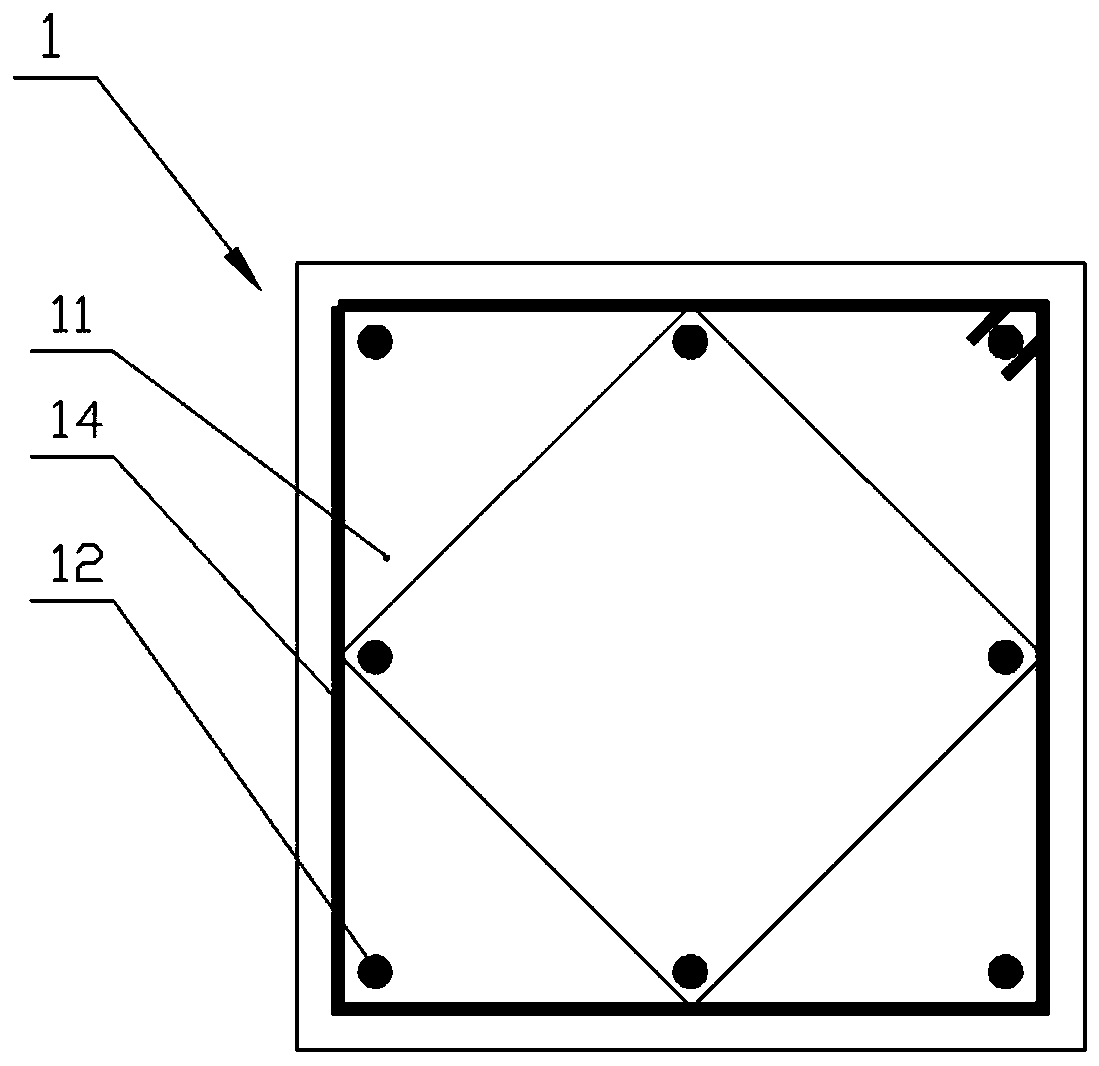

[0035] Such as figure 2 As shown, the prefabricated column 1 includes a column main body 11 and column connecting ribs 12; wherein the column main body 11 is a rectangular main body formed by pouring concrete, and the lower end of the column main body 11 is provided with a protruding core tenon 13 to facilitate the positioning of the prefabricated column when connecting The column connecting rib 12 is the steel bar that both ends are rolled with straight threads, the column connecting rib is arranged along the length direction of the column main body, and is separately located around the column main body, each edge connecting rib of the column main body is arranged along the column height and the le...

Embodiment 2

[0044] Preferred embodiment two, such as Figure 5 As shown, the difference between this embodiment and the preferred embodiment 1 is that the steel column foot 4 is used instead of the threaded sleeve 3 as the connecting piece between the upper and lower prefabricated columns.

[0045] Such as Figure 5 , Figure 6 As shown, the steel column foot 4 includes a top plate 41, a bottom plate 42 and a rib 43, and each rib is arranged in a well-shaped shape and is arranged between the top plate and the bottom plate. The ribs separate several independent areas on the top plate and the bottom plate. Each area There are connecting holes inside, and the column feet are welded in the factory. When assembling, the end (threaded) of the column connecting rib passes through the connecting hole and then tightened by a nut.

[0046] Compared with sleeve grouting, the present invention has the following advantages:

[0047] (1) Convenient processing and simple operation;

[0048] (2) The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com