Double steel plate concrete composite energy dissipation coupling beam, and construction method

A construction method and concrete technology, which are applied in the directions of structural elements, building components, and elongated structural components for load-bearing, etc., can solve problems such as difficulty in meeting expected requirements, poor deformation capacity and energy dissipation capacity, etc. The effect of optimizing the seismic performance and the convenient operation of the construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

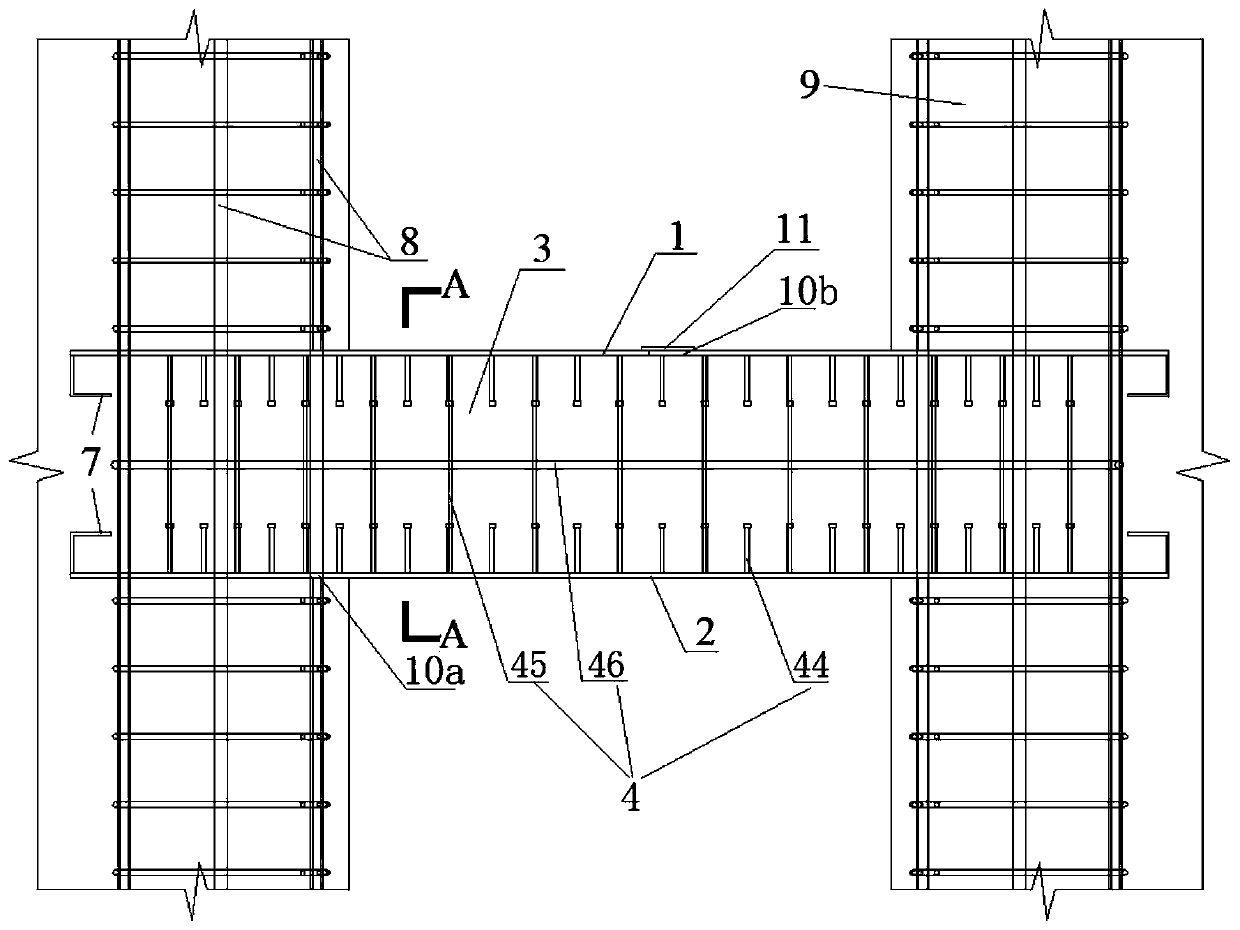

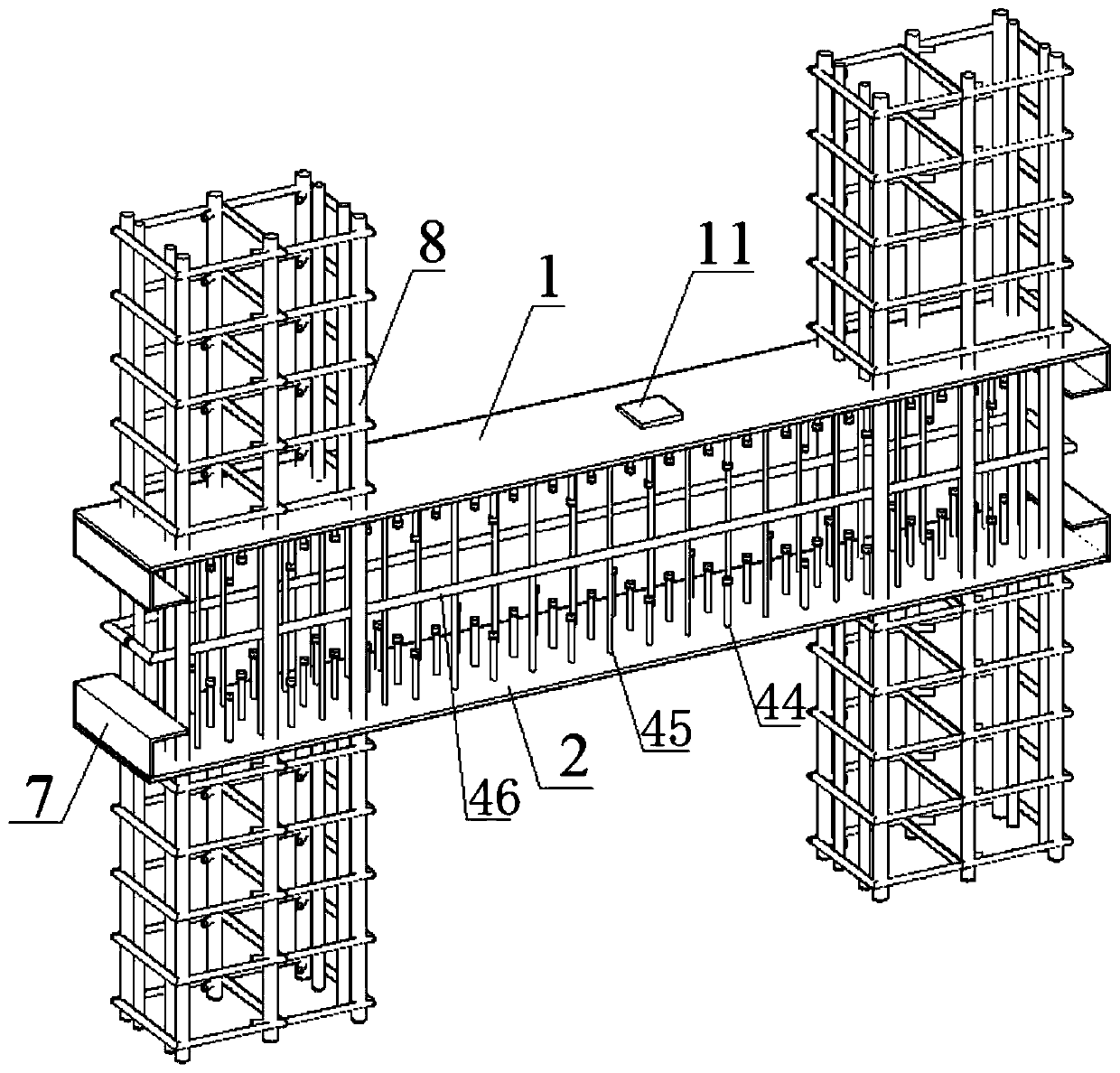

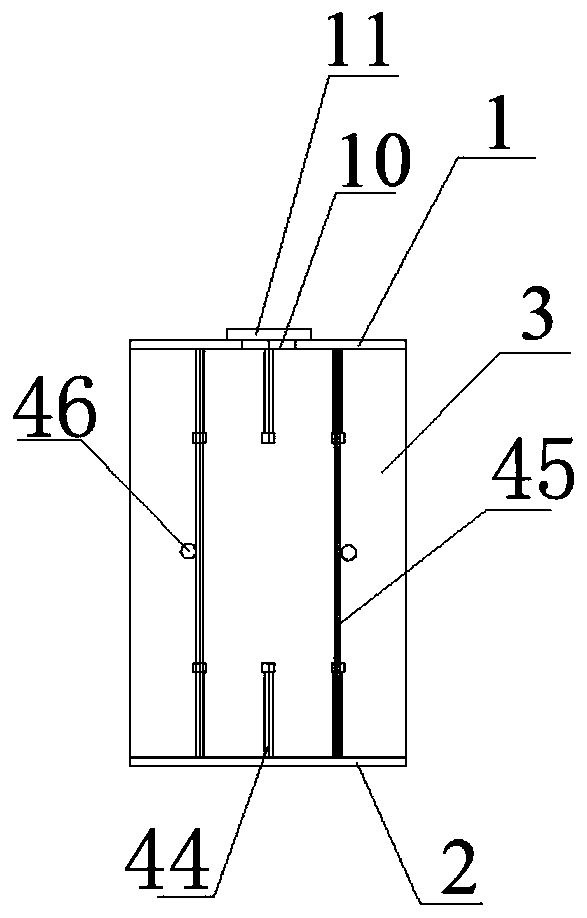

[0029] combine Figure 1 to Figure 3 As shown, a double-steel plate concrete composite energy-dissipating connecting beam includes a horizontally arranged first steel plate 1, a second steel plate 2, a steel skeleton 4 connecting the two steel plates, and an inner filling concrete 3 poured between the two steel plates. The first steel plate 1 , the second steel plate 2 and the inner concrete 3 form a "sandwich" structure, and the two steel plates and the inner concrete 3 are connected by a steel skeleton 4 to form a whole. The two ends of the first steel plate 1 and the second steel plate 2 extend into the shear wall plinth 9 respectively, and the two steel plates are respectively provided with holes 10a at the positions where the longitudinal steel bar 8 passes through the pier, so as to ensure the restraint of the edge members of the pier The longitudinal reinforcement 8 runs continuously through the steel plate. The two ends of the first steel plate 1 and the second steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com