Manual mortar packer for construction and decoration project, and using method

A stuffer and engineering technology, applied in building maintenance, construction, building construction, etc., can solve the problems of uneven stuffing technology of operators, difficult stuffing technology, affecting the quality of the project, etc. Good effect, realize the effect of economic investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

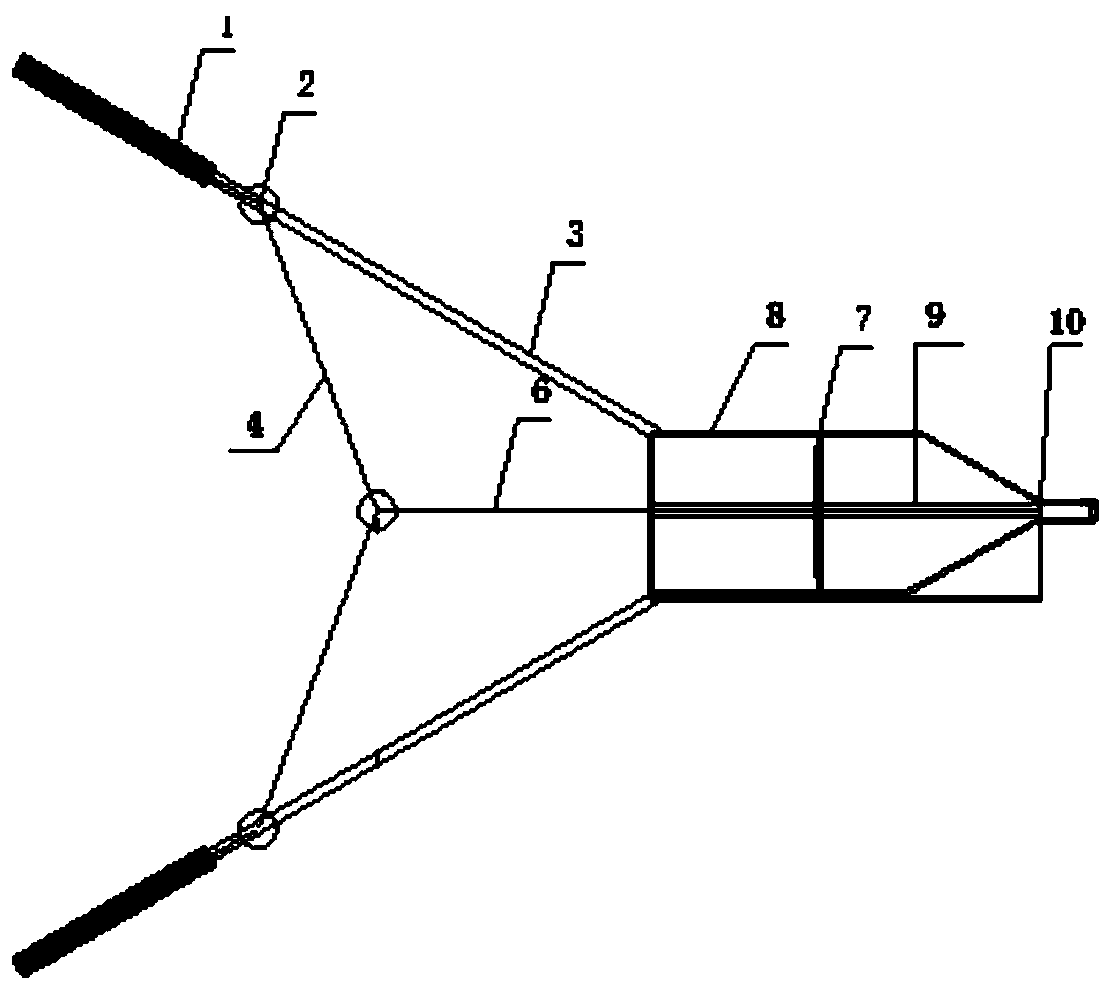

[0028] Combine below figure 1 , detailing the structural composition of the manual mortar packer used in construction and decoration engineering of the present invention.

[0029] Please refer to figure 1 , a manual mortar packer used in construction and decoration projects, including a pressure rod 6, a push plate 7, a slurry / 8, the front end of the pressure rod 6 is sleeved with a support rod 9; the push plate 7 is sleeved on the support rod 9 Above; the slurry chamber 8 is sleeved on the periphery of the push plate 7 through the support rod 9, the front end of the slurry chamber 8 is provided with a nozzle 10, and the rear end of the slurry chamber 8 is provided with a pair of brackets 3; 2 A pair of hinged push rods 4 are hingedly connected to the corresponding brackets 3, so that the two push rods 4 and one pressure rod 6 are hingedly connected to the end of the pressure rod 6, and the two brackets 3 can drive the pressure rod 6 Push the push plate 7 to move toward th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com