Fault detection method and system for desorption control valve of fuel evaporation and emission system

A technology of evaporative emission and desorption control, applied in engine control, fuel injection control, electrical control, etc., can solve the problems of low detection frequency and accuracy, oscillation of fuel tank pressure signal, difficulty in meeting detection frequency, etc., to improve accuracy , the effect of increasing the amount of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] This embodiment provides a fault detection method for the desorption control valve of the evaporative emission system, which is used for detecting the normally open fault of the desorption control valve of the fuel evaporative emission system of the vehicle, wherein the fuel evaporative emission system of the vehicle can also be called the vehicle's Fuel evaporative emission control system. First, in order to facilitate the understanding of the fault detection method for the desorption control valve of the evaporative emission system provided in this embodiment, the fuel evaporative emission control system and the engine air intake system of the vehicle are firstly described in this embodiment.

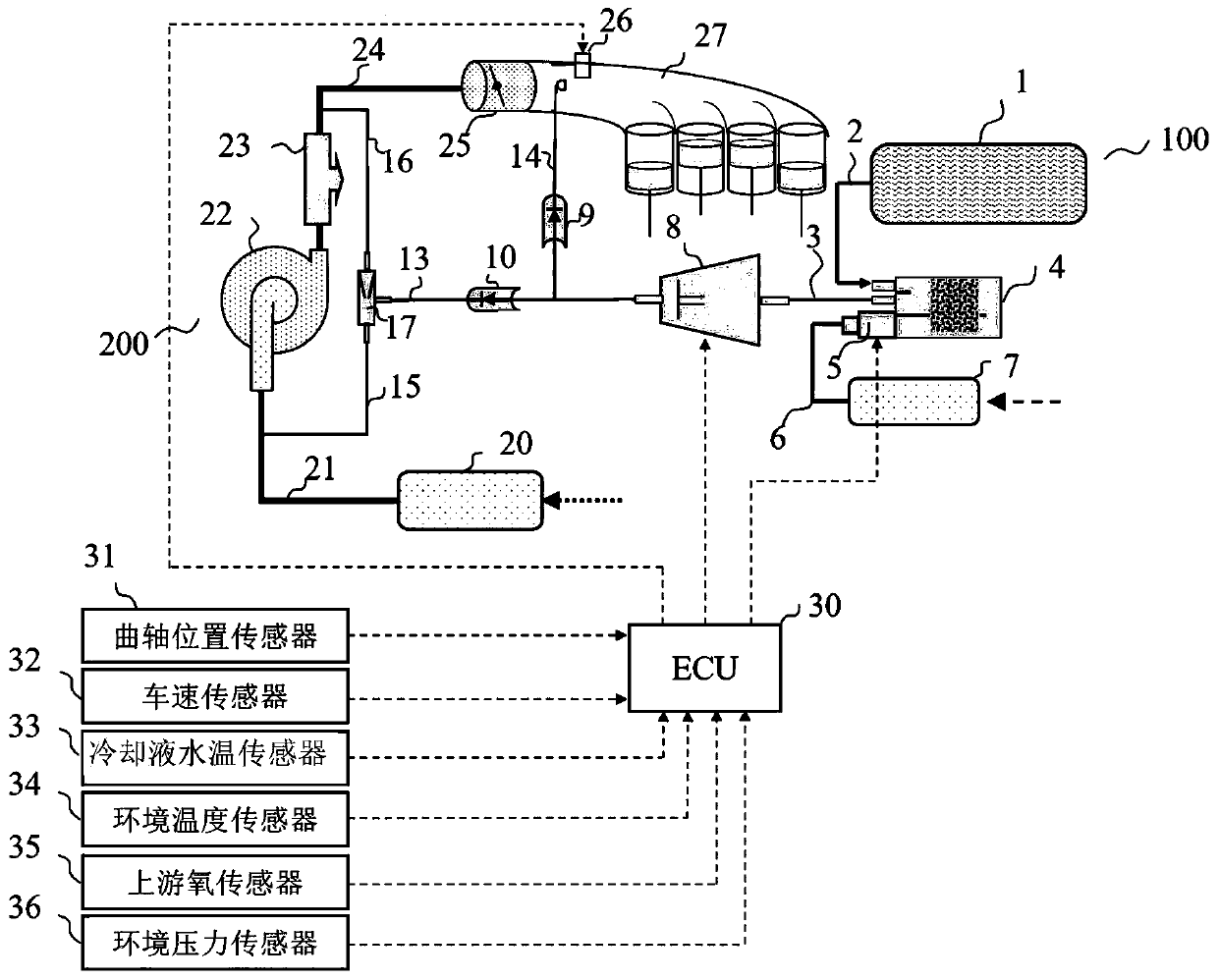

[0059] For example, as figure 1 As shown, the vehicle includes an evaporative emissions system 100 and an engine intake system 200 .

[0060] Among them, the evaporative emission system includes a fuel tank 1, a fourth vacuum pipeline 2, an activated carbon tank 4, a detection...

Embodiment 2

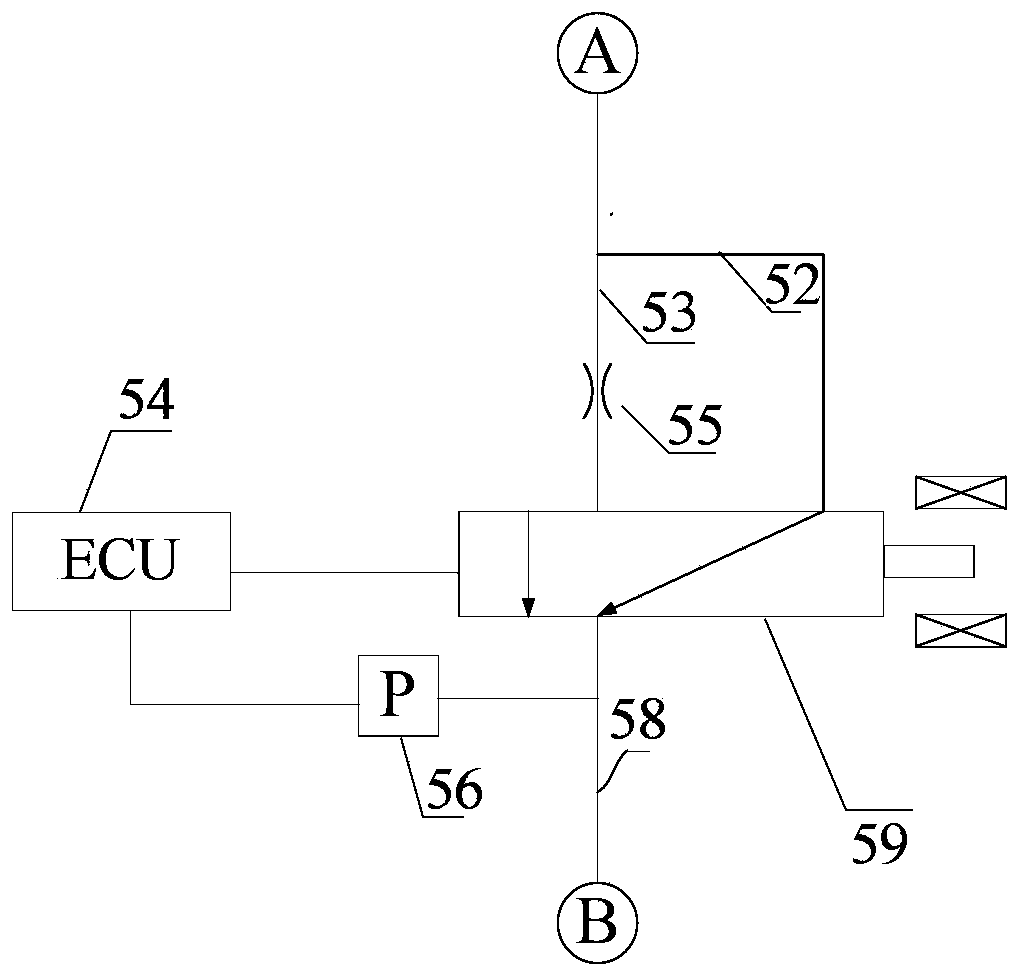

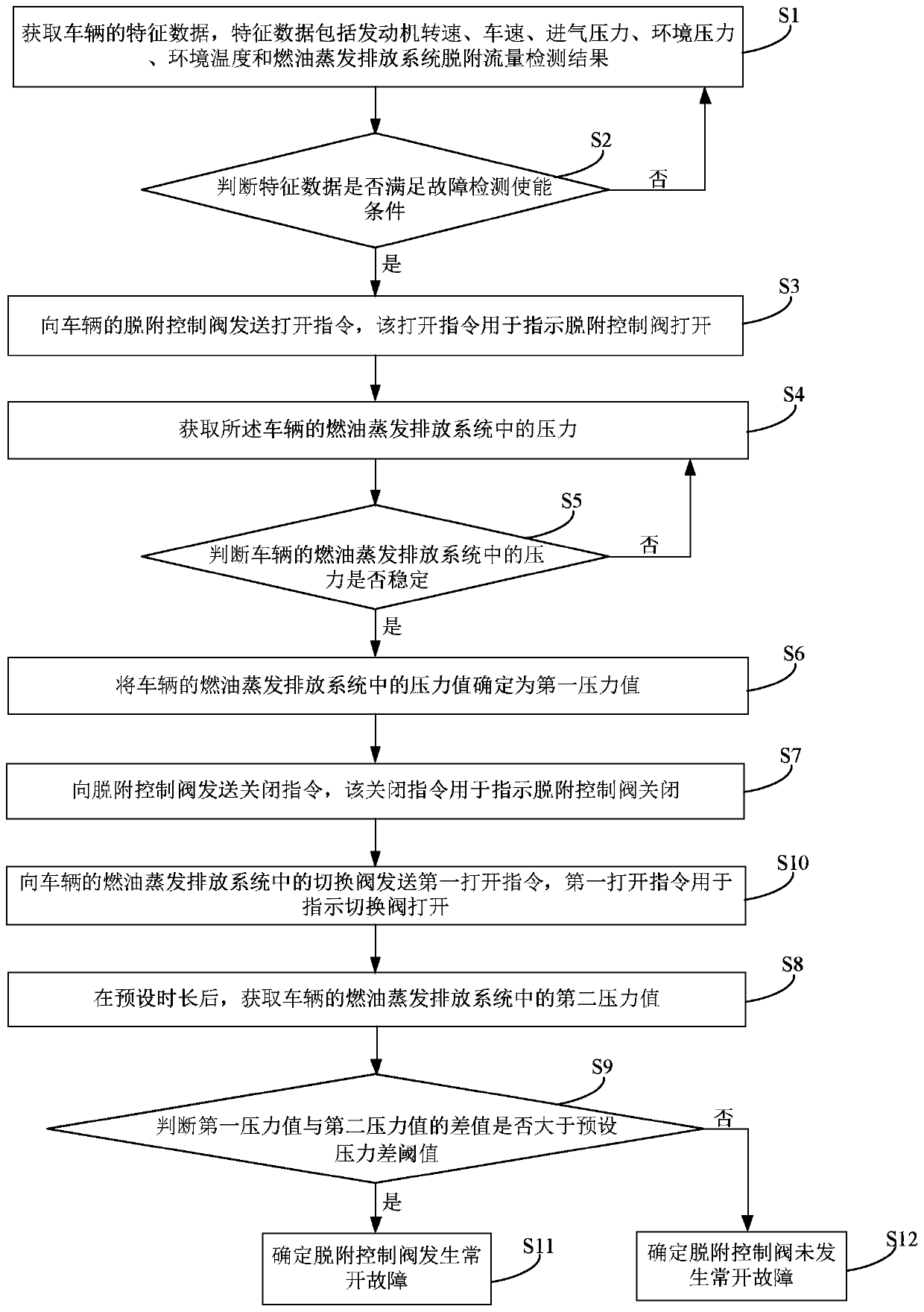

[0068] This embodiment can be implemented by the fuel evaporative emission system desorption control valve fault detection system, the fuel evaporative emission system desorption control valve fault detection system can be implemented by software and / or hardware, the fuel evaporative emission system desorption control valve The valve fault detection system can be integrated in the vehicle's ECU. The method provided in this embodiment can be applied to the embodiment and various optional implementations of the fault detection system for the desorption control valve of the fuel evaporative emission system. Such as image 3 As shown, the fault detection method for the desorption control valve of the fuel evaporative emission system includes the following steps:

[0069] S1. Obtain the characteristic data of the vehicle, which includes engine speed, vehicle speed, intake pressure, ambient pressure, ambient temperature and detection results of the desorption flow rate of the fuel ...

Embodiment 3

[0094] This embodiment provides a fault detection system for the desorption control valve of the fuel evaporative emission system, which can implement the above-mentioned fault detection method for the desorption control valve of the fuel evaporative emission system. Specifically, such as Figure 5 As shown, the fuel evaporative emission system desorption control valve fault detection system includes:

[0095] The first obtaining device 501 is used to obtain characteristic data of the vehicle, the characteristic data includes engine speed, vehicle speed, intake pressure, ambient pressure, ambient temperature and detection results of desorption flow rate of the fuel evaporative emission system;

[0096] The first judging means 502 is used to judge whether the feature data satisfies the enabling condition of fault detection;

[0097] The first sending device 503 is used to send an opening instruction to the desorption control valve of the vehicle when the characteristic data me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com